Item | Phenomenon | Cause | Factory | Inspection, repair or adjustment | |

standard | |||||

|

|

|

| ||

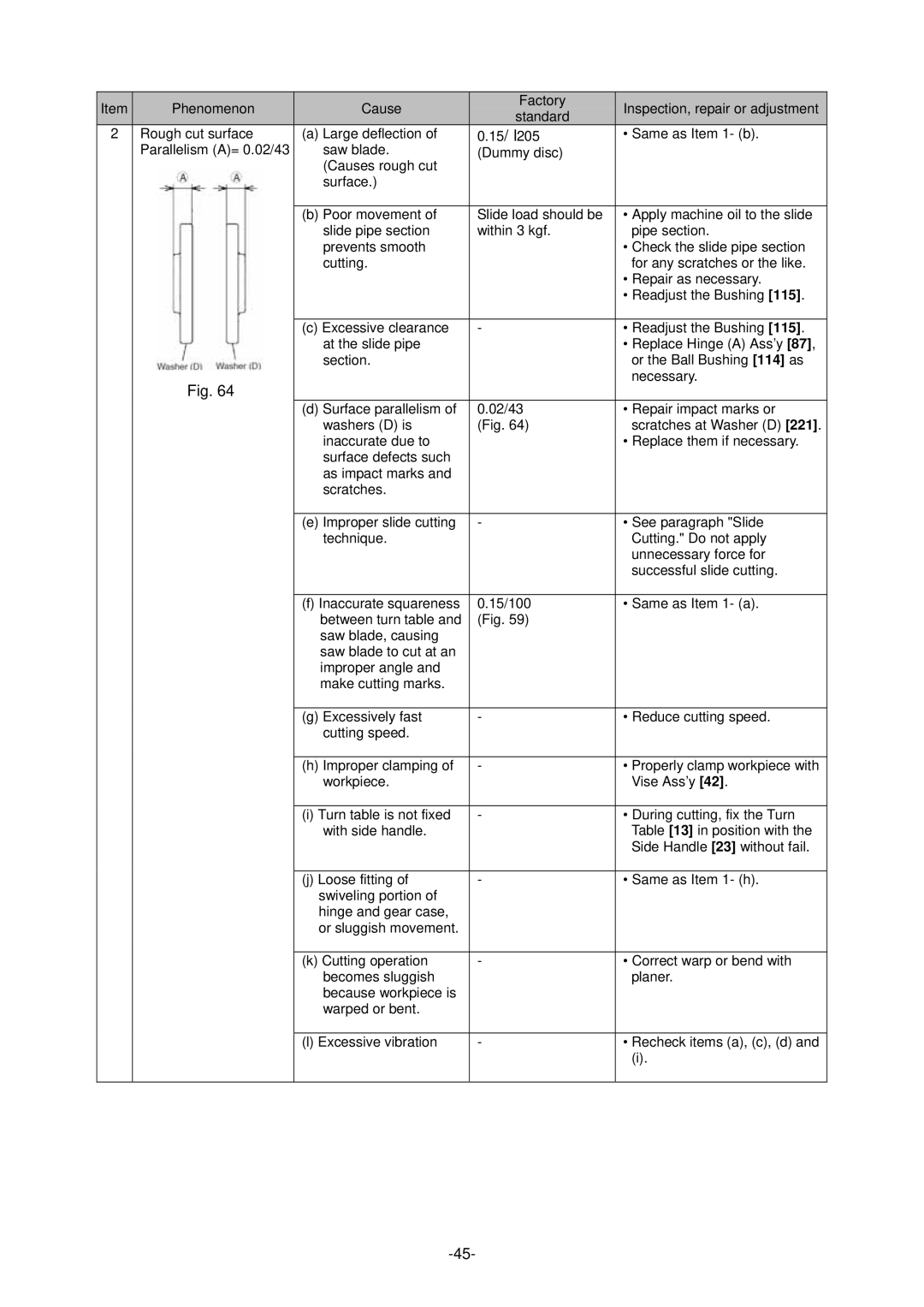

2 | Rough cut surface | (a) Large deflection of | φ | • Same as Item 1- (b). | |

| Parallelism (A)= 0.02/43 | saw blade. | 0.15/ 205 |

| |

| (Dummy disc) |

| |||

|

| (Causes rough cut |

|

| |

|

| surface.) |

|

| |

|

|

|

|

| |

|

| (b) Poor movement of | Slide load should be | • Apply machine oil to the slide | |

|

| slide pipe section | within 3 kgf. | pipe section. | |

|

| prevents smooth |

| • Check the slide pipe section | |

|

| cutting. |

| for any scratches or the like. | |

|

|

|

| • Repair as necessary. | |

|

|

|

| • Readjust the Bushing [115]. | |

|

|

|

|

| |

|

| (c) Excessive clearance | - | • Readjust the Bushing [115]. | |

|

| at the slide pipe |

| • Replace Hinge (A) Ass’y [87], | |

|

| section. |

| or the Ball Bushing [114] as | |

| Fig. 64 |

|

| necessary. | |

|

|

|

| ||

|

| (d) Surface parallelism of | 0.02/43 | • Repair impact marks or | |

|

| washers (D) is | (Fig. 64) | scratches at Washer (D) [221]. | |

|

| inaccurate due to |

| • Replace them if necessary. | |

|

| surface defects such |

|

| |

|

| as impact marks and |

|

| |

|

| scratches. |

|

| |

|

|

|

|

| |

|

| (e) Improper slide cutting | - | • See paragraph "Slide | |

|

| technique. |

| Cutting." Do not apply | |

|

|

|

| unnecessary force for | |

|

|

|

| successful slide cutting. | |

|

|

|

|

| |

|

| (f) Inaccurate squareness | 0.15/100 | • Same as Item 1- (a). | |

|

| between turn table and | (Fig. 59) |

| |

|

| saw blade, causing |

|

| |

|

| saw blade to cut at an |

|

| |

|

| improper angle and |

|

| |

|

| make cutting marks. |

|

| |

|

|

|

|

| |

|

| (g) Excessively fast | - | • Reduce cutting speed. | |

|

| cutting speed. |

|

| |

|

|

|

|

| |

|

| (h) Improper clamping of | - | • Properly clamp workpiece with | |

|

| workpiece. |

| Vise Ass’y [42]. | |

|

|

|

|

| |

|

| (i) Turn table is not fixed | - | • During cutting, fix the Turn | |

|

| with side handle. |

| Table [13] in position with the | |

|

|

|

| Side Handle [23] without fail. | |

|

|

|

|

| |

|

| (j) Loose fitting of | - | • Same as Item 1- (h). | |

|

| swiveling portion of |

|

| |

|

| hinge and gear case, |

|

| |

|

| or sluggish movement. |

|

| |

|

|

|

|

| |

|

| (k) Cutting operation | - | • Correct warp or bend with | |

|

| becomes sluggish |

| planer. | |

|

| because workpiece is |

|

| |

|

| warped or bent. |

|

| |

|

|

|

|

| |

|

| (l) Excessive vibration | - | • Recheck items (a), (c), (d) and | |

|

|

|

| (i). | |

|

|

|

|

|