NOTE:

Techniques to avoid unwanted cutting marks

Uneven and unwanted cutting marks can be avoided by shifting from 3 press cutting to 4 slide cutting in a single, uninterrupted motion.

Techniques to avoid burnt marks

Burnt marks can be avoided by shifting from 3 press cutting to 4 slide cutting in a single, uninterrupted motion in the same manner as the above, applying a slight lateral force toward the

(5)Miter cutting

Miter cutting is accomplished by turning the turn table. (For details, please refer to the Instruction Manual "Miter cutting procedures.")

(6)Bevel cutting

Bevel cutting of 0 - 45° to the left or 0 - 5° to the right is accomplished by inclining the motor head section. (For details, refer to the Instruction Manual "Bevel cutting procedures.")

WARNING: When the workpiece is secured on the left or right side of the blade, the short

CAUTION: When cutting a workpiece of 50 mm

(7)Compound (miter + bevel) cutting

Compound (miter + bevel) cutting can be accomplished by combining the miter cutting and bevel cutting operations described in paragraphs (5) and (6) above. (For details, refer to the Instruction Manual "Compound cutting procedures.") When the saw blade is inclined 45° to the left, the turn table can be turned up to 45° to the left and right.

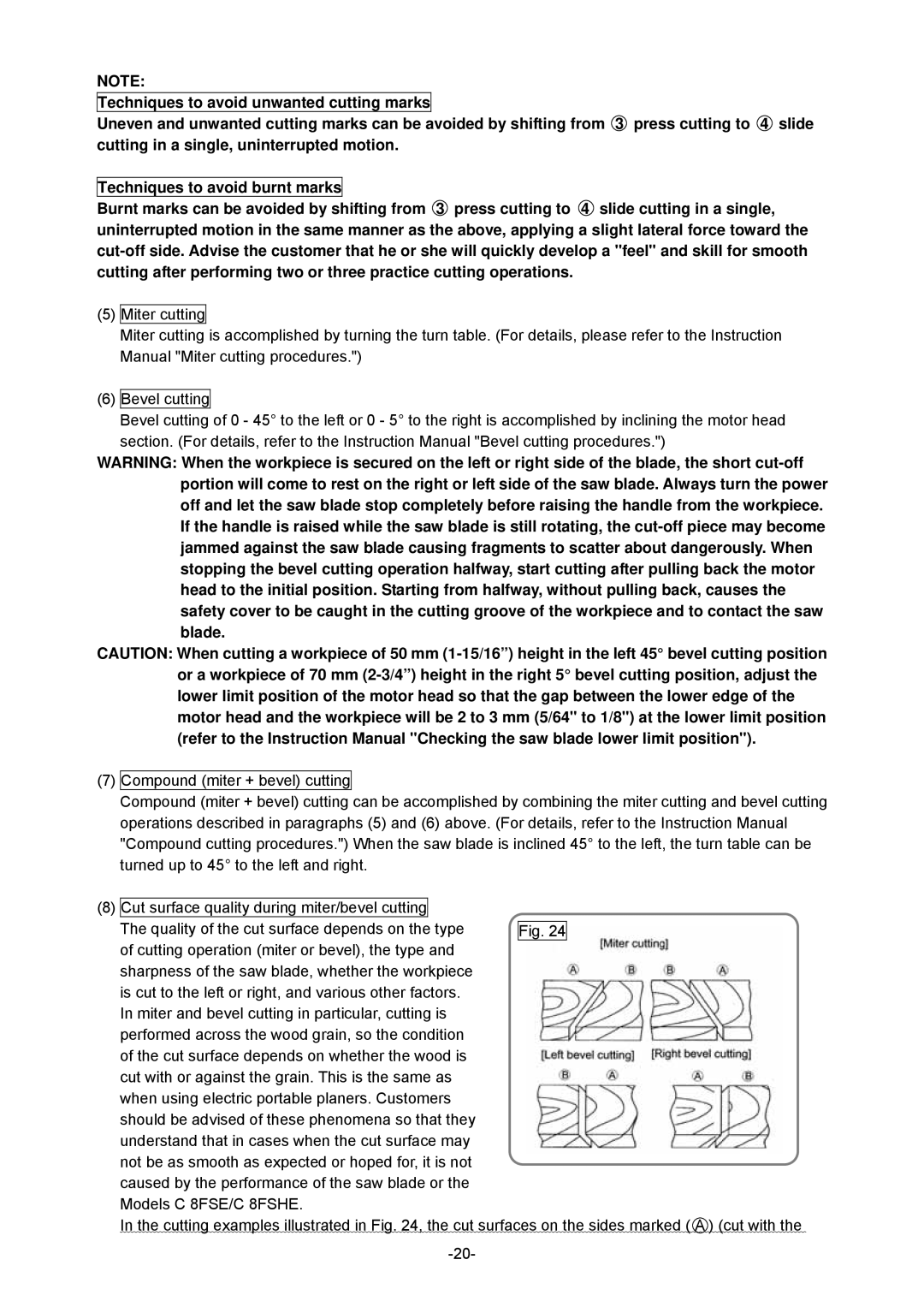

(8)Cut surface quality during miter/bevel cutting

The quality of the cut surface depends on the type of cutting operation (miter or bevel), the type and sharpness of the saw blade, whether the workpiece is cut to the left or right, and various other factors. In miter and bevel cutting in particular, cutting is performed across the wood grain, so the condition of the cut surface depends on whether the wood is cut with or against the grain. This is the same as when using electric portable planers. Customers should be advised of these phenomena so that they understand that in cases when the cut surface may not be as smooth as expected or hoped for, it is not caused by the performance of the saw blade or the Models C 8FSE/C 8FSHE.

In the cutting examples illustrated in Fig. 24, the cut surfaces on the sides marked ( A ) (cut with the