of the laser line. (Repeat this operation 3 or 4 times depending on the adjusting conditions of the laser marker.) Refer to the above "(1) Construction of laser marker and functions of each component" for the relation between the two Seal Lock Hex. Socket Set Screws M5 x 6 [103] and the laser line.

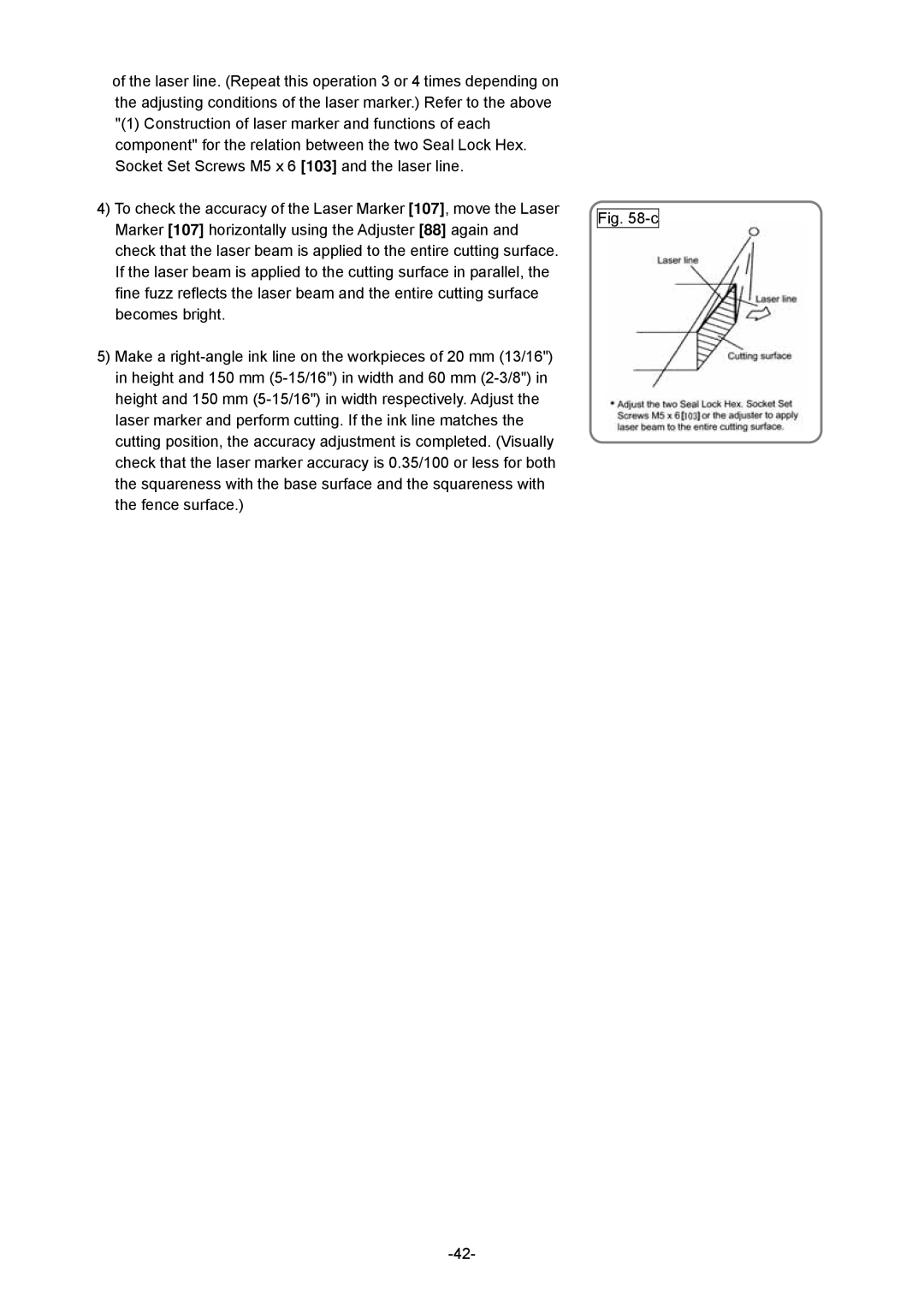

4)To check the accuracy of the Laser Marker [107], move the Laser Marker [107] horizontally using the Adjuster [88] again and check that the laser beam is applied to the entire cutting surface. If the laser beam is applied to the cutting surface in parallel, the fine fuzz reflects the laser beam and the entire cutting surface becomes bright.

5)Make a

Fig.