DKM-500BAH specifications

The Hoshizaki DKM-500BAH is a high-performing ice maker renowned in the food service industry for its reliability and efficiency. This unit excels in producing crescent-style ice, which is highly sought after for its ability to chill beverages effectively while minimizing dilution. The Hoshizaki reputation for quality is well-reflected in the DKM-500BAH, making it a popular choice in restaurants, bars, and other establishments that demand high ice production capacity.One of the standout features of the DKM-500BAH is its impressive ice production capability. This model has the capacity to produce up to 500 pounds of ice per day, ensuring that businesses with high-volume demands can meet their needs without interruption. The unit operates on a refrigerant system designed for optimal energy efficiency, which can lower operating costs and contribute to sustainability goals.

The DKM-500BAH utilizes advanced technology, including Hoshizaki's patented ice-making mechanism. This system features a stainless steel evaporator that enhances durability and ice quality. The crescent-shaped ice it produces has a slower melt rate, making it perfect for restaurants and bars that focus on customer experience. Additionally, the unit is equipped with a cycle control that ensures ice is produced consistently.

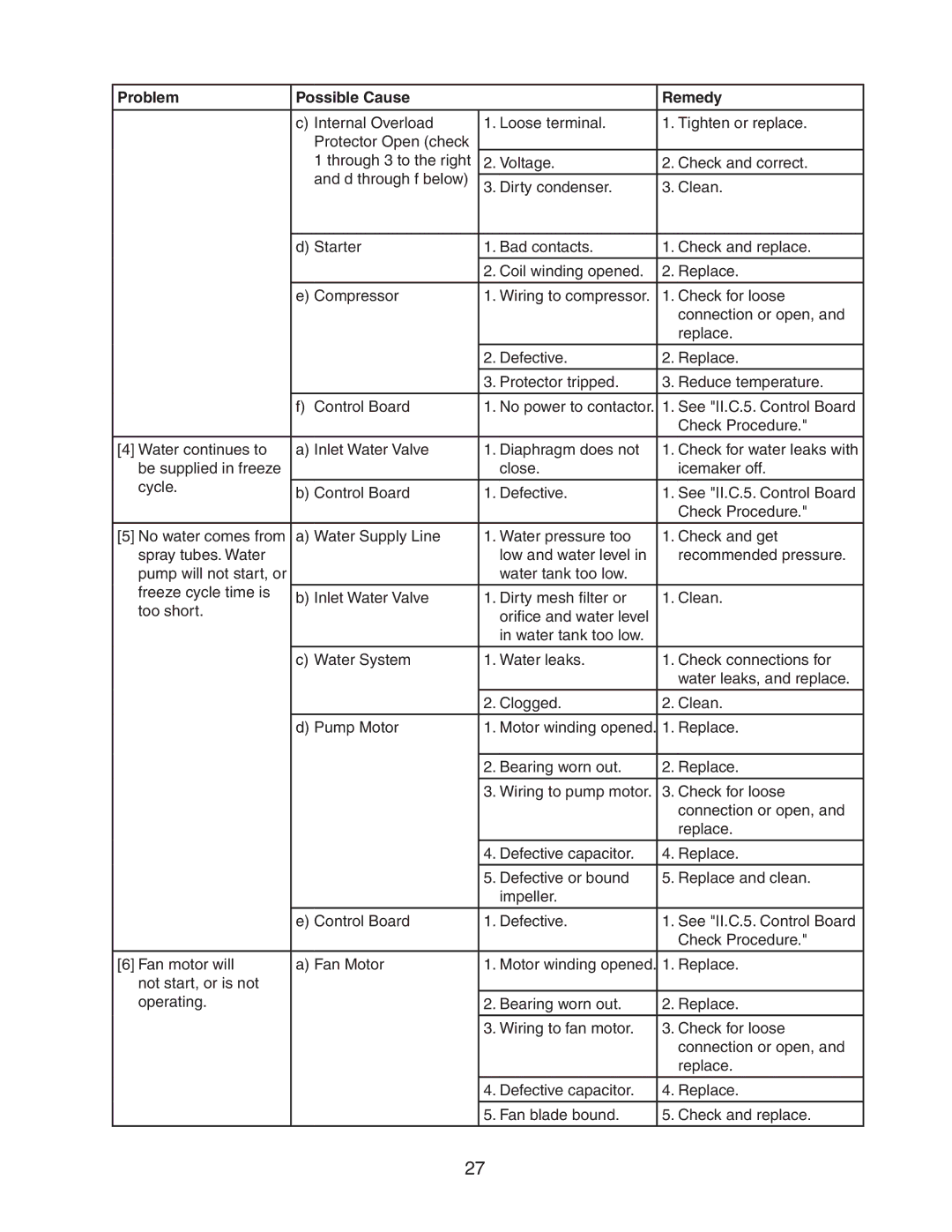

Another critical aspect of the DKM-500BAH is its user-friendly design. It features a front-facing control panel that allows for easy monitoring and adjustment of settings. A built-in diagnostics system alerts users to potential issues, enabling prompt maintenance and reducing downtime. The removable air filter is another convenience, making it simple to clean and maintain the unit’s efficiency.

Moreover, the construction of the DKM-500BAH is noteworthy. It features a corrosion-resistant stainless steel exterior that ensures longevity and maintains hygiene standards. The unit also has an insulated storage bin that holds up to 250 pounds of ice, making it an efficient solution for busy settings.

In summary, the Hoshizaki DKM-500BAH is a robust ice maker that combines high production capacity, advanced technology, and user-friendly features. Its build quality and efficient performance position it as a leader in the commercial ice-making market, making it an ideal investment for establishments requiring reliable ice supply.