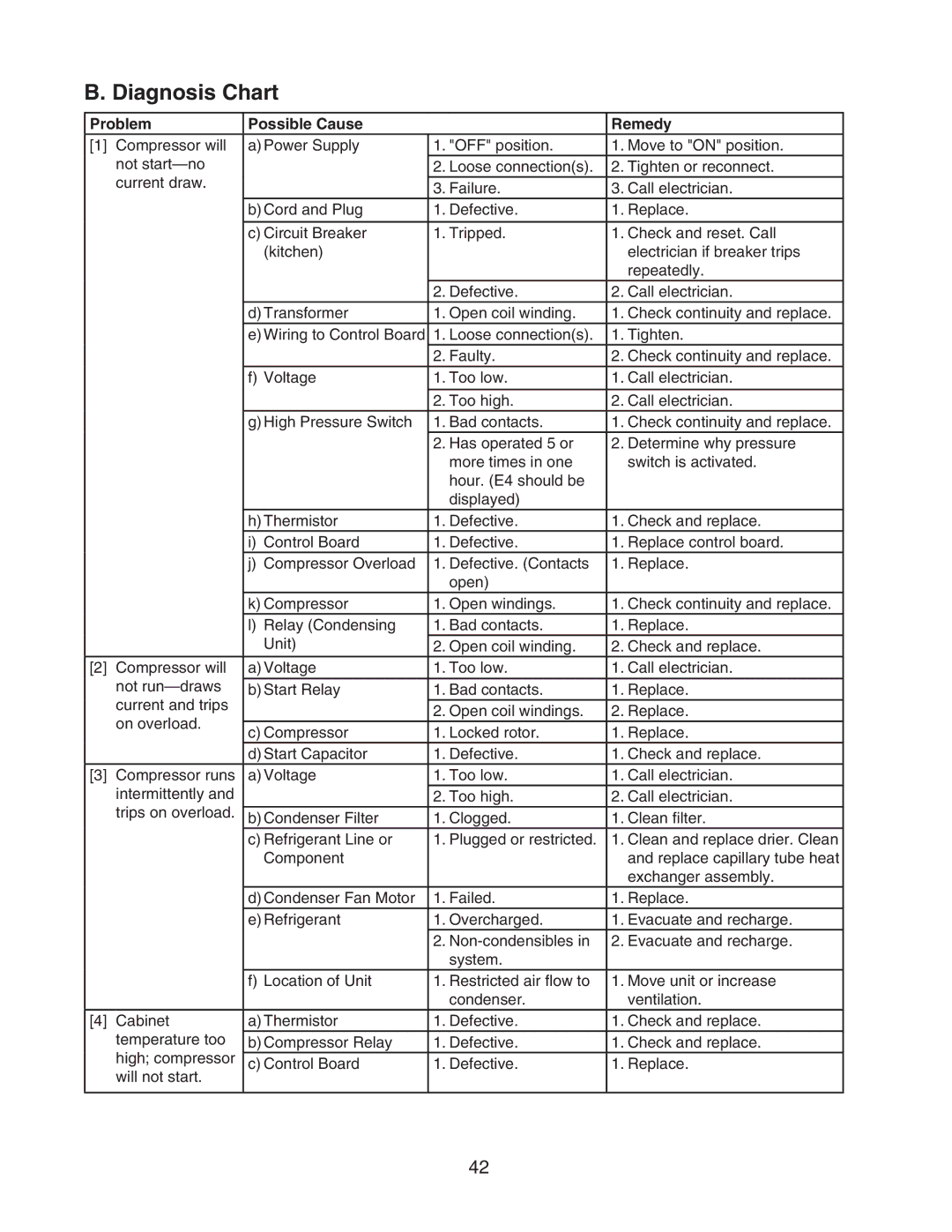

B. Diagnosis Chart

Problem | Possible Cause |

| Remedy | |

[1] | Compressor will | a)Power Supply | 1. "OFF" position. | 1. Move to "ON" position. |

| not |

| 2. Loose connection(s). | 2. Tighten or reconnect. |

| current draw. |

|

|

|

|

| 3. Failure. | 3. Call electrician. | |

|

|

| ||

|

| b) Cord and Plug | 1. Defective. | 1. Replace. |

|

|

|

|

|

|

| c) Circuit Breaker | 1. Tripped. | 1. Check and reset. Call |

|

| (kitchen) |

| electrician if breaker trips |

|

|

|

| repeatedly. |

|

|

| 2. Defective. | 2. Call electrician. |

|

| d)Transformer | 1. Open coil winding. | 1. Check continuity and replace. |

|

| e)Wiring to Control Board | 1. Loose connection(s). | 1. Tighten. |

|

|

| 2. Faulty. | 2. Check continuity and replace. |

|

| f) Voltage | 1. Too low. | 1. Call electrician. |

|

|

|

|

|

|

|

| 2. Too high. | 2. Call electrician. |

|

| g)High Pressure Switch | 1. Bad contacts. | 1. Check continuity and replace. |

|

|

| 2. Has operated 5 or | 2. Determine why pressure |

|

|

| more times in one | switch is activated. |

|

|

| hour. (E4 should be |

|

|

|

| displayed) |

|

|

| h)Thermistor | 1. Defective. | 1. Check and replace. |

|

| i) Control Board | 1. Defective. | 1. Replace control board. |

|

| j) Compressor Overload | 1. Defective. (Contacts | 1. Replace. |

|

|

| open) |

|

|

| k) Compressor | 1. Open windings. | 1. Check continuity and replace. |

|

| l) Relay (Condensing | 1. Bad contacts. | 1. Replace. |

|

| Unit) | 2. Open coil winding. | 2. Check and replace. |

[2] | Compressor will | a)Voltage | 1. Too low. | 1. Call electrician. |

| not | b)Start Relay | 1. Bad contacts. | 1. Replace. |

| current and trips |

|

|

|

|

| 2. Open coil windings. | 2. Replace. | |

| on overload. |

| ||

| c) Compressor | 1. Locked rotor. | 1. Replace. | |

|

| |||

|

| d)Start Capacitor | 1. Defective. | 1. Check and replace. |

[3] | Compressor runs | a)Voltage | 1. Too low. | 1. Call electrician. |

| intermittently and |

| 2. Too high. | 2. Call electrician. |

| trips on overload. |

|

|

|

| b)Condenser Filter | 1. Clogged. | 1. Clean filter. | |

|

| c) Refrigerant Line or | 1. Plugged or restricted. | 1. Clean and replace drier. Clean |

|

| Component |

| and replace capillary tube heat |

|

|

|

| exchanger assembly. |

|

| d)Condenser Fan Motor | 1. Failed. | 1. Replace. |

|

| e)Refrigerant | 1. Overcharged. | 1. Evacuate and recharge. |

|

|

| 2. | 2. Evacuate and recharge. |

|

|

| system. |

|

|

| f) Location of Unit | 1. Restricted air flow to | 1. Move unit or increase |

|

|

| condenser. | ventilation. |

[4] | Cabinet | a)Thermistor | 1. Defective. | 1. Check and replace. |

| temperature too | b)Compressor Relay | 1. Defective. | 1. Check and replace. |

| high; compressor |

|

|

|

| c) Control Board | 1. Defective. | 1. Replace. | |

| will not start. |

|

|

|

|

|

|

|

|

42