Troubleshooting

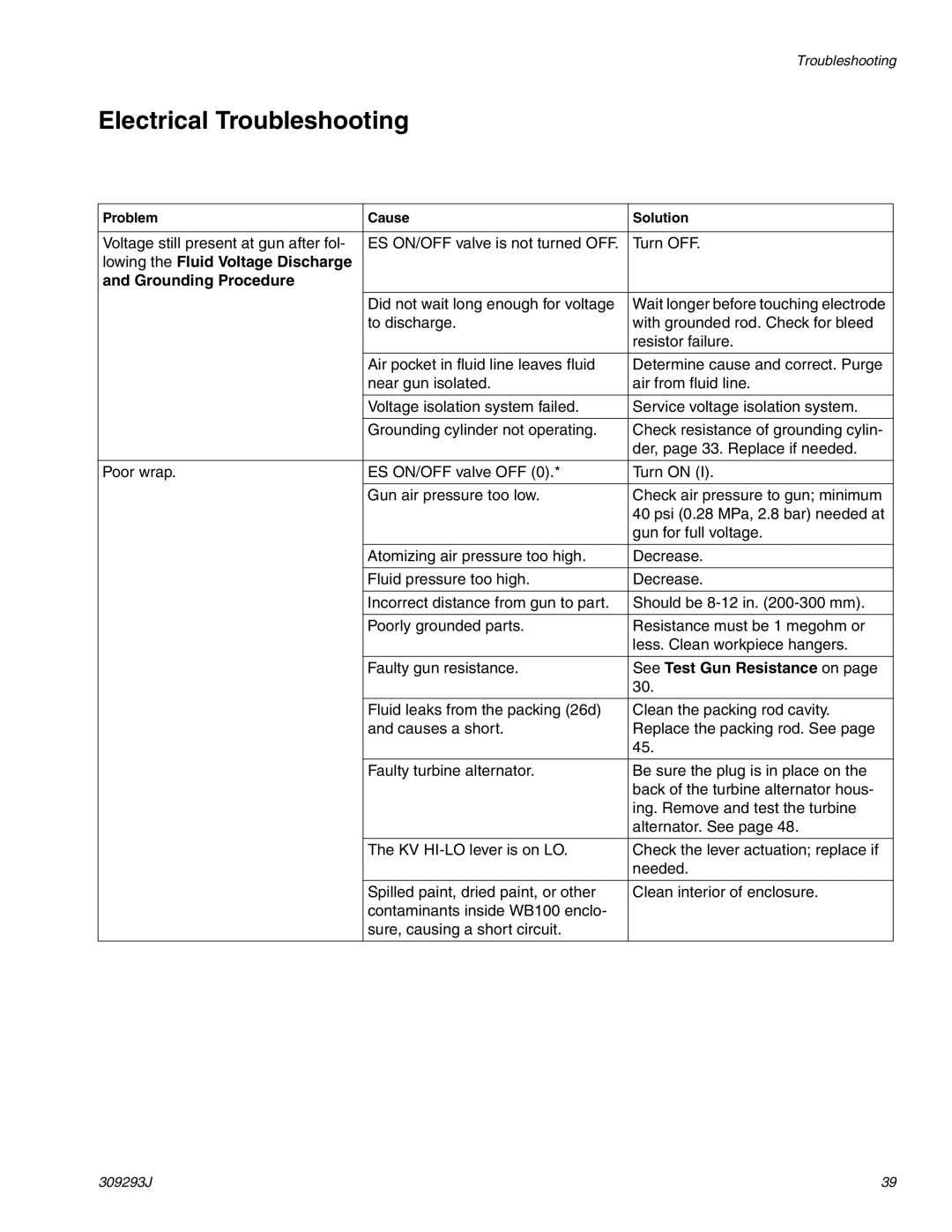

Electrical Troubleshooting

Problem | Cause | Solution |

|

|

|

Voltage still present at gun after fol- | ES ON/OFF valve is not turned OFF. | Turn OFF. |

lowing the Fluid Voltage Discharge |

|

|

and Grounding Procedure |

|

|

|

|

|

| Did not wait long enough for voltage | Wait longer before touching electrode |

| to discharge. | with grounded rod. Check for bleed |

|

| resistor failure. |

|

|

|

| Air pocket in fluid line leaves fluid | Determine cause and correct. Purge |

| near gun isolated. | air from fluid line. |

|

|

|

| Voltage isolation system failed. | Service voltage isolation system. |

|

|

|

| Grounding cylinder not operating. | Check resistance of grounding cylin- |

|

| der, page 33. Replace if needed. |

|

|

|

Poor wrap. | ES ON/OFF valve OFF (0).* | Turn ON (I). |

|

|

|

| Gun air pressure too low. | Check air pressure to gun; minimum |

|

| 40 psi (0.28 MPa, 2.8 bar) needed at |

|

| gun for full voltage. |

|

|

|

| Atomizing air pressure too high. | Decrease. |

|

|

|

| Fluid pressure too high. | Decrease. |

|

|

|

| Incorrect distance from gun to part. | Should be |

|

|

|

| Poorly grounded parts. | Resistance must be 1 megohm or |

|

| less. Clean workpiece hangers. |

|

|

|

| Faulty gun resistance. | See Test Gun Resistance on page |

|

| 30. |

|

|

|

| Fluid leaks from the packing (26d) | Clean the packing rod cavity. |

| and causes a short. | Replace the packing rod. See page |

|

| 45. |

|

|

|

| Faulty turbine alternator. | Be sure the plug is in place on the |

|

| back of the turbine alternator hous- |

|

| ing. Remove and test the turbine |

|

| alternator. See page 48. |

|

|

|

| The KV | Check the lever actuation; replace if |

|

| needed. |

|

|

|

| Spilled paint, dried paint, or other | Clean interior of enclosure. |

| contaminants inside WB100 enclo- |

|

| sure, causing a short circuit. |

|

|

|

|

309293J | 39 |