|

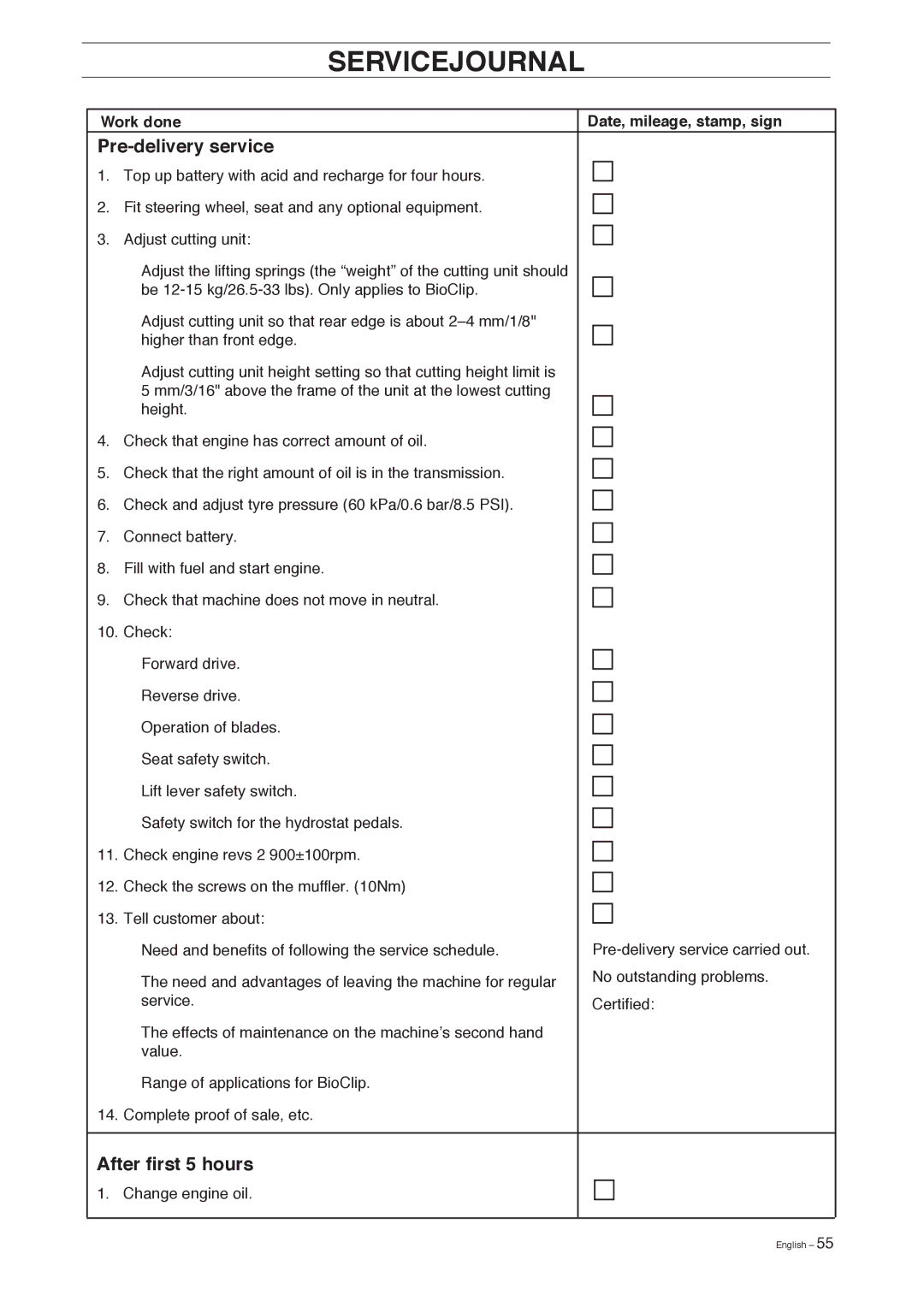

| SERVICEJOURNAL |

|

| |

|

|

|

|

|

|

| Work done |

| Date, mileage, stamp, sign | ||

|

|

|

|

| |

| 1. | Top up battery with acid and recharge for four hours. |

|

|

|

| 2. | Fit steering wheel, seat and any optional equipment. |

|

|

|

| 3. | Adjust cutting unit: |

|

|

|

|

| Adjust the lifting springs (the “weight” of the cutting unit should |

|

|

|

|

| be |

|

|

|

|

| Adjust cutting unit so that rear edge is about |

|

|

|

|

| higher than front edge. |

|

|

|

|

| Adjust cutting unit height setting so that cutting height limit is |

|

|

|

|

| 5 mm/3/16" above the frame of the unit at the lowest cutting |

|

|

|

|

| height. |

|

|

|

| 4. | Check that engine has correct amount of oil. |

|

|

|

| 5. | Check that the right amount of oil is in the transmission. |

|

|

|

| 6. | Check and adjust tyre pressure (60 kPa/0.6 bar/8.5 PSI). |

|

|

|

| 7. | Connect battery. |

|

|

|

| 8. | Fill with fuel and start engine. |

|

|

|

| 9. | Check that machine does not move in neutral. |

|

|

|

| 10. Check: |

|

|

| |

|

| Forward drive. |

|

|

|

|

| Reverse drive. |

|

|

|

|

| Operation of blades. |

|

|

|

|

| Seat safety switch. |

|

|

|

|

| Lift lever safety switch. |

|

|

|

|

| Safety switch for the hydrostat pedals. |

|

|

|

| 11. Check engine revs 2 900±100rpm. |

|

|

| |

| 12. Check the screws on the muffler. (10Nm) |

|

|

| |

| 13. Tell customer about: |

|

|

| |

|

| Need and benefits of following the service schedule. |

| ||

|

| The need and advantages of leaving the machine for regular |

| No outstanding problems. | |

|

|

|

|

| |

|

| service. |

| Certified: | |

|

| The effects of maintenance on the machine’s second hand |

|

|

|

|

| value. |

|

|

|

|

| Range of applications for BioClip. |

|

|

|

| 14. Complete proof of sale, etc. |

|

|

| |

|

|

|

|

| |

| After first 5 hours |

|

|

| |

| 1. | Change engine oil. |

|

|

|

|

|

|

|

|

|

English – 55