Installation (cont’d.)

CORNER WEDGES

Corner wedges are attached via front and rear camlocks. Use a 7mm Allen wrench to turn the locks. Do not over- tighten! Join the top by using a joint bracket (included in joint kit) with 3/8" bolts.

JOINT TRIM

After cases have been leveled and joined, and refrigera- tion, electrical, and wasted piping work completed, install the splashguards. Fasten along the top edge, or center, with #10 X 3/3" sheet metal screws.

DO NOT SEAL JOINT TRIM TO FLOOR!

Plumbing

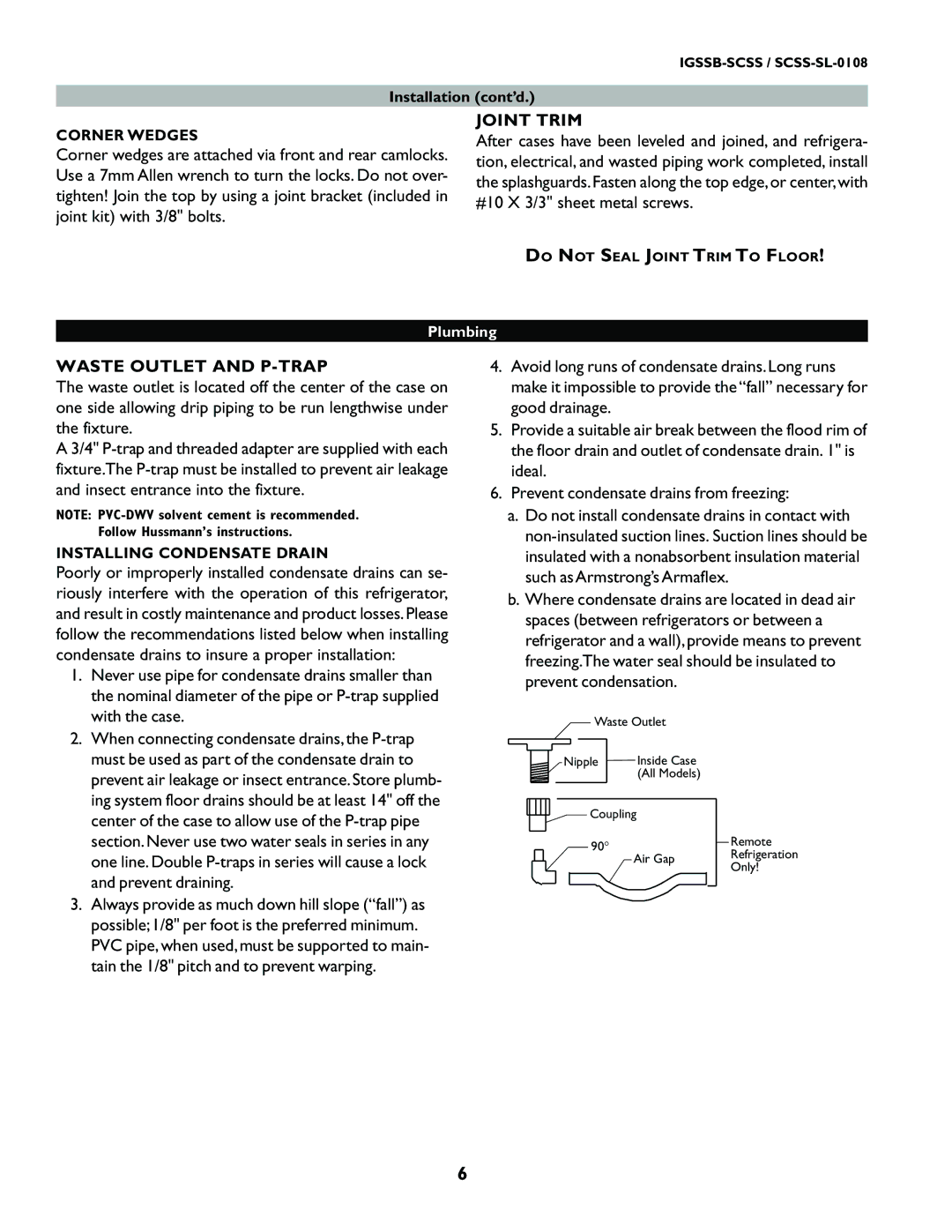

WASTE OUTLET AND P-TRAP

The waste outlet is located off the center of the case on one side allowing drip piping to be run lengthwise under the fixture.

A 3/4"

NOTE:

INSTALLING CONDENSATE DRAIN

Poorly or improperly installed condensate drains can se- riously interfere with the operation of this refrigerator, and result in costly maintenance and product losses. Please follow the recommendations listed below when installing condensate drains to insure a proper installation:

1.Never use pipe for condensate drains smaller than the nominal diameter of the pipe or

2.When connecting condensate drains, the

3.Always provide as much down hill slope (“fall”) as possible; 1/8" per foot is the preferred minimum. PVC pipe, when used, must be supported to main- tain the 1/8" pitch and to prevent warping.

4.Avoid long runs of condensate drains. Long runs make it impossible to provide the “fall” necessary for good drainage.

5.Provide a suitable air break between the flood rim of the floor drain and outlet of condensate drain. 1" is ideal.

6.Prevent condensate drains from freezing:

a.Do not install condensate drains in contact with

b.Where condensate drains are located in dead air spaces (between refrigerators or between a refrigerator and a wall), provide means to prevent freezing.The water seal should be insulated to prevent condensation.

Waste Outlet |

|

| |

Nipple | Inside Case |

|

|

| (All Models) |

|

|

Coupling |

|

| |

90° |

|

| Remote |

|

| ||

| Air Gap |

| Refrigeration |

|

| Only! | |

|

|

| |

6