Rev. 0108

Appendices

APPENDIX A. – TEMPERATURE

GUIDELINES

REFRIGERATED

The refrigerators should be operated according to Hussmann’s published engineering specifications for en- tering air temperatures for specific equipment applica- tions. Table 1 shows the typical temperature of the air entering the food zone one hour before the start of defrost and one hour after defrost for various categories of refrigerators. Refer to Appendix C for Field Evaluation Guidelines.

|

|

|

| TABLE 1 | ||||||||||

|

|

| TYPE OF | TYPICAL ENTERING | ||||||||||

| REFRIGERATOR | AIR TEMPERATURE | ||||||||||||

| I. OPEN DISPLAY |

|

|

|

|

|

|

|

|

| ||||

|

| A. Non frozen: |

|

|

|

|

|

|

|

|

| |||

| 1) | Meat |

|

|

| 28°F | ||||||||

| 2) | Dairy/Deli |

|

|

| 32°F | ||||||||

| 3) | Produce |

|

|

|

|

|

|

|

|

| |||

|

|

|

| a. Processed |

|

|

| 36°F | ||||||

|

|

|

| b. Unprocessed |

|

|

| 45°F | ||||||

|

| B. Frozen |

|

|

| 0°F | ||||||||

|

| C. Ice Cream |

|

|

| |||||||||

| II. CLOSED DISPLAY |

|

|

|

|

|

|

|

|

| ||||

|

| A. Non frozen: |

|

|

|

|

|

|

|

|

| |||

| 1) | Meat |

|

|

| 34°F | ||||||||

| 2) | Dairy/Deli |

|

|

| 34°F | ||||||||

| 3) | Produce |

|

|

|

|

|

|

|

|

| |||

|

|

|

| a. Processed |

|

|

| 36°F | ||||||

|

|

|

| b. Unprocessed |

|

|

| 45°F | ||||||

|

| B. Frozen |

|

|

| 0°F | ||||||||

|

| C. Ice Cream |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

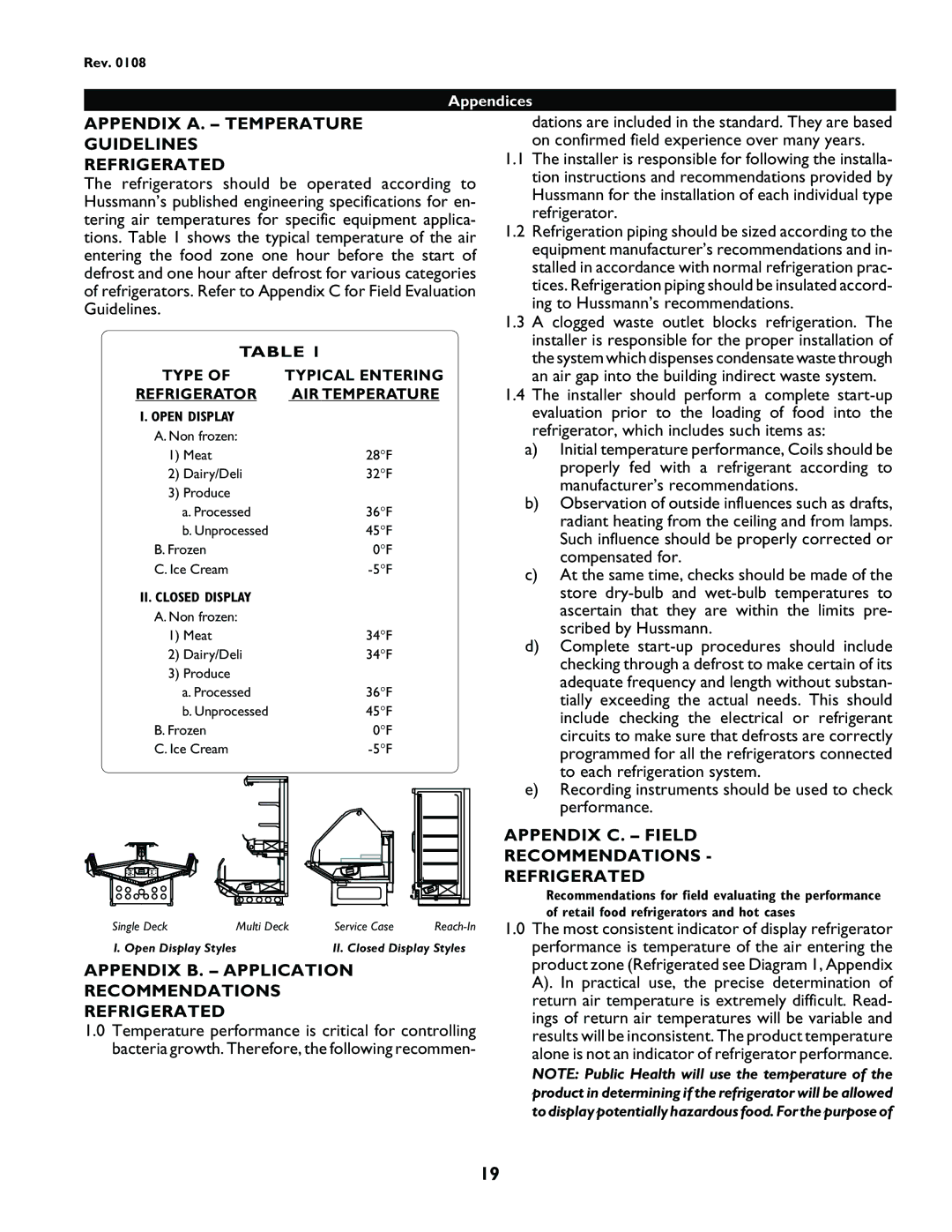

Single Deck | Multi Deck | Service Case | |

I. Open Display Styles | II. Closed Display Styles | ||

APPENDIX B. – APPLICATION

RECOMMENDATIONS

REFRIGERATED

1.0Temperature performance is critical for controlling bacteria growth. Therefore, the following recommen-

dations are included in the standard. They are based on confirmed field experience over many years.

1.1The installer is responsible for following the installa- tion instructions and recommendations provided by Hussmann for the installation of each individual type refrigerator.

1.2Refrigeration piping should be sized according to the equipment manufacturer’s recommendations and in- stalled in accordance with normal refrigeration prac- tices. Refrigeration piping should be insulated accord- ing to Hussmann’s recommendations.

1.3A clogged waste outlet blocks refrigeration. The installer is responsible for the proper installation of the system which dispenses condensate waste through an air gap into the building indirect waste system.

1.4The installer should perform a complete

a)Initial temperature performance, Coils should be properly fed with a refrigerant according to manufacturer’s recommendations.

b)Observation of outside influences such as drafts, radiant heating from the ceiling and from lamps. Such influence should be properly corrected or compensated for.

c)At the same time, checks should be made of the store

d)Complete

e)Recording instruments should be used to check performance.

APPENDIX C. – FIELD

RECOMMENDATIONS -

REFRIGERATED

Recommendations for field evaluating the performance of retail food refrigerators and hot cases

1.0The most consistent indicator of display refrigerator performance is temperature of the air entering the product zone (Refrigerated see Diagram 1, Appendix A). In practical use, the precise determination of return air temperature is extremely difficult. Read- ings of return air temperatures will be variable and results will be inconsistent. The product temperature alone is not an indicator of refrigerator performance.

NOTE: Public Health will use the temperature of the product in determining if the refrigerator will be allowed to display potentially hazardous food. For the purpose of

19