TROUBLESHOOTING | PROCEDURE 2 | |

| MOTOR BRUSH INSPECTION | |

| (FIGURE 4) | BRAKE TEST (FIGURE 5) |

There are two (2) contact brushes on the motors located under the brush caps on the motor housing. If these caps are hard to remove they are either overtightened or the motor has become very hot. Let motors cool. If caps still cannot be removed, it is recommended that the motor be sent to Invacare Technical Services for inspection/repair.

NOTE: It is very important to note which way the brush comes out of the motor. The brush MUST be placed into the motor exactly the same way to ensure good contact with the commutator.

1.Once the motor brush caps have been removed, pull the brushes out of the motor. The end of the brushes should be smooth and shiny and the spring should not be damaged or discolored. If one or both of the brushes are damaged, only the damaged or worn brushes need be replaced. It is very important that any time a brush is replaced, it must be “burned in”. Thisisaccomplishedbyrunningthemotorforonehour in each direction with a half hour break

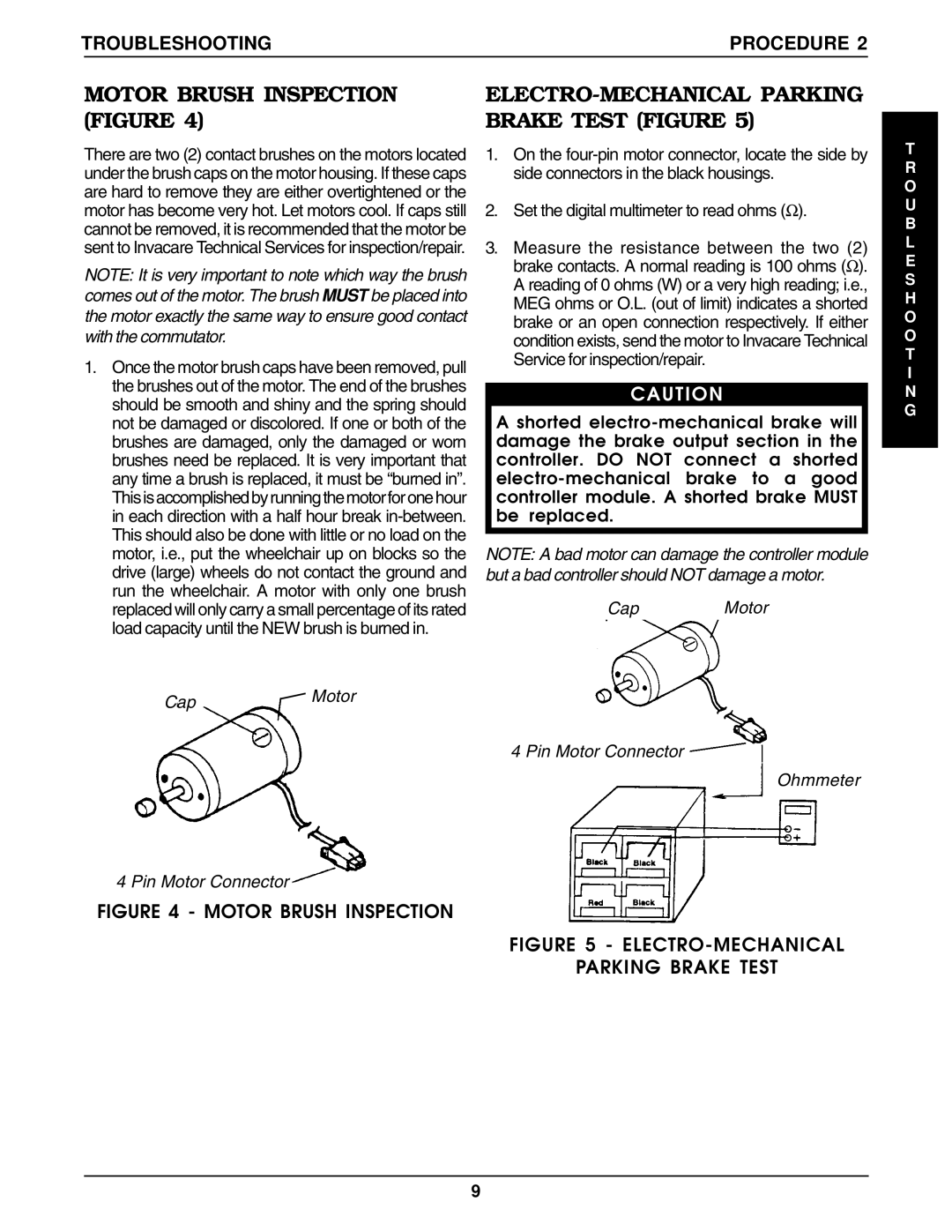

1.On the

2.Set the digital multimeter to read ohms (Ω ).

3.Measure the resistance between the two (2) brake contacts. A normal reading is 100 ohms (Ω ). A reading of 0 ohms (W) or a very high reading; i.e., MEG ohms or O.L. (out of limit) indicates a shorted brake or an open connection respectively. If either condition exists, send the motor to Invacare Technical Service for inspection/repair.

CAUTION

Ashorted

NOTE: A bad motor can damage the controller module but a bad controller should NOT damage a motor.

Cap Motor

T R O U B L E S H O O T I N G

Cap | Motor |

|

4 Pin Motor Connector

Ohmmeter

4 Pin Motor Connector

FIGURE 4 - MOTOR BRUSH INSPECTION

FIGURE 5 - ELECTRO-MECHANICAL

PARKING BRAKE TEST

9