Figure 26

10.3Table to blade alignment

Refer to Figures 27 and 28.

The table has been set square with blade by the manufacturer and no adjustment is necessary now. As the saw receives extensive use, however, table/blade squareness should be checked occasionally and corrected if necessary. Use the miter slot to do this:

1.Disconnect saw from power source.

2.Raise blade to maximum height.

3.Mark one tooth (A) with a grease pencil and position the tooth slightly above the top edge of table at the front.

Figure 27

4.Raise the miter gauge slightly out of its slot to serve as a shoulder. Using a sliding square (B) against the side of the bar, slide the scale over until it touches the tip of the blade, and lock the scale in position. See Figure 27.

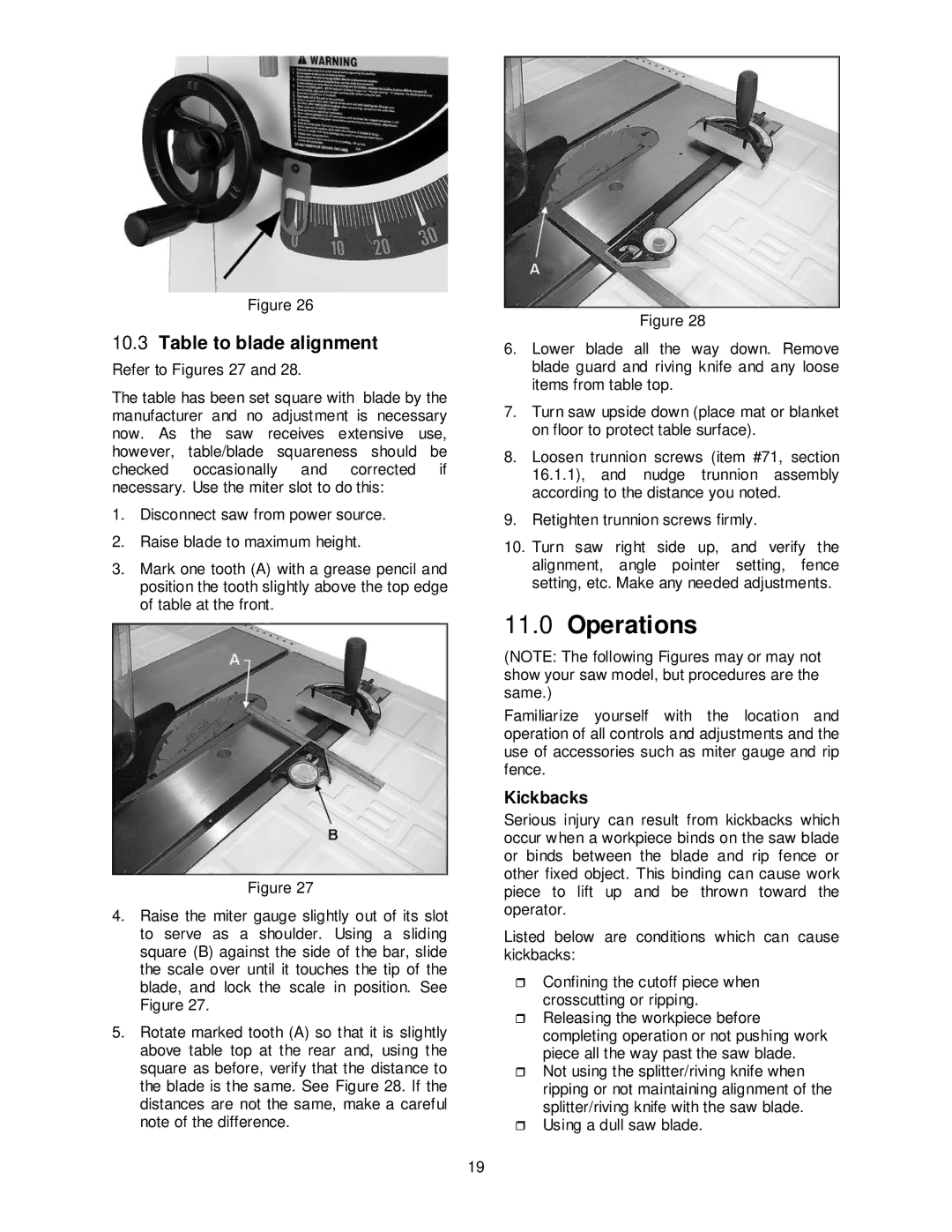

5.Rotate marked tooth (A) so that it is slightly above table top at the rear and, using the square as before, verify that the distance to the blade is the same. See Figure 28. If the distances are not the same, make a careful note of the difference.

19

Figure 28

6.Lower blade all the way down. Remove blade guard and riving knife and any loose items from table top.

7.Turn saw upside down (place mat or blanket on floor to protect table surface).

8.Loosen trunnion screws (item #71, section 16.1.1), and nudge trunnion assembly according to the distance you noted.

9.Retighten trunnion screws firmly.

10.Turn saw right side up, and verify the alignment, angle pointer setting, fence setting, etc. Make any needed adjustments.

11.0Operations

(NOTE: The following Figures may or may not show your saw model, but procedures are the same.)

Familiarize yourself with the location and operation of all controls and adjustments and the use of accessories such as miter gauge and rip fence.

Kickbacks

Serious injury can result from kickbacks which occur when a workpiece binds on the saw blade or binds between the blade and rip fence or other fixed object. This binding can cause work piece to lift up and be thrown toward the operator.

Listed below are conditions which can cause kickbacks:

Confining the cutoff piece when crosscutting or ripping.

Releasing the workpiece before completing operation or not pushing work piece all the way past the saw blade.

Not using the splitter/riving knife when ripping or not maintaining alignment of the splitter/riving knife with the saw blade.

Using a dull saw blade.