| 13.0 | Maintenance |

|

| Always disconnect power to |

| the machine before performing maintenance. | |

| Failure to do this may result in serious | |

| personal injury. | |

| Cleaning | |

| Clean the | |

| below to ensure maximum performance. | |

| ||

| assumes the saw is being used every day. | |

| Daily: |

|

| Wipe down the table surface and | |

| with a rust preventive. | |

| Clean pitch and resin from the saw blade. | |

| Weekly: | |

| Clean motor housing with compressed air. | |

| Wipe down fence rails with a dry silicon | |

| lubricant. | |

| Lubrication | |

| Lubricate the areas indicated below every 12 | |

| months. |

|

| Lubricate blade angling trunnions with 6 or | |

| 7 drops of light machine oil. | |

| Lubricate the blade height trunnion with 6 | |

| or 7 drops of light machine oil. | |

| Worm gears and threads should be | |

| lubricated with an automotive wheel | |

| bearing grease. | |

| Check all adjustments after lubricating. | |

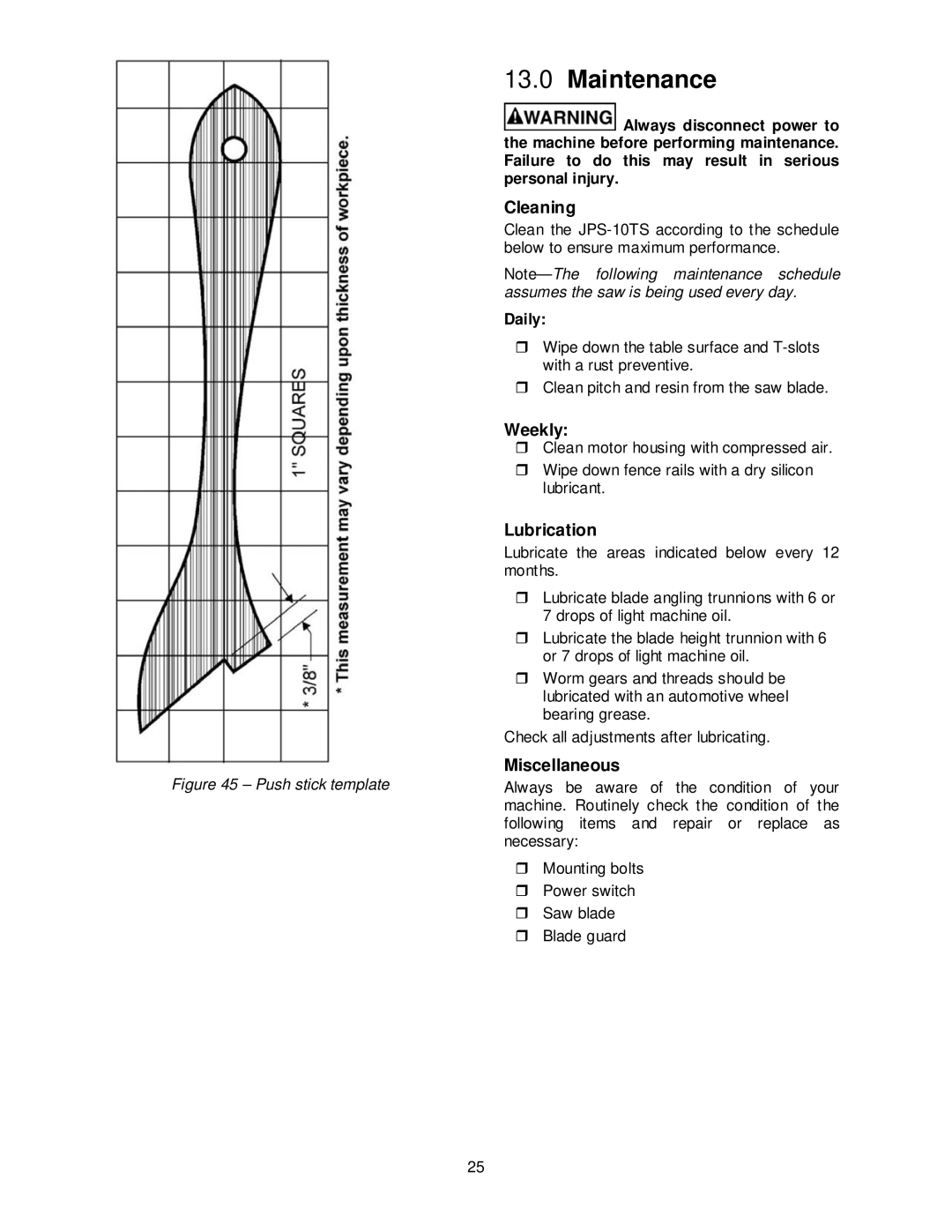

Figure 45 – Push stick template | Miscellaneous | |

Always | be aware of the condition of your | |

| machine. Routinely check the condition of the | |

| following items and repair or replace as | |

| necessary: | |

Mounting bolts Power switch Saw blade

Blade guard

25