Venting Requirements

There are three types of venting configurations approved for use with the Lillehammer gas stove:

•Hearthmount Co-Linear (Vertical Termination)

•Vertical Venting (Vert ical Termination)

•Horizontal Termination (Horizontal Termination)

The Lillehammer is approved for use with the vent systems listed below. Use parts of one manu- facturer only - DO NOT MIX VENT COMPONENTS FROM DIFFERENT MANUFACTURERS IN THE SAME SYSTEM.

•Simpson Dura-Vent GS

•Amerivent Corporation

•Security Vent Ltd.

Installation of any components not manufac- tured or approved by Jøtul or failure to meet all clearance requirements will void all warranties and could result in property damage, bodily injury, or serious fire.

The approved vent configurations described in this manual are derived from extensive testing under controlled laboratory conditions. Gas appli- ance performance can be negatively affected by variables present in the installation environment, i.e: atmospheric pressure, strong prevailing winds, adjacent structures and trees, snow accumulation, etc. These conditions should be taken into consider- ation by the installer and stove owner when plan- ning the vent system design.

IMPORTANT

•JOINT SEALING REQUIREMENT: APPLY A 1/8” BEAD OF HIGH- TEMPERATURE (750°F) SEAL-

ANT TO THE MALE SECTION OF

THE INNER VENT PIPE. SEE FIG. 9. THE CEMENT SHOULD FORM A SEAL BETWEEN THE INNER AND OUTER PIPES.

• NEVER MODIFY ANY VENTING COMPONENT, OR USE

ANY DAMAGED VENTING PRODUCT.

•THE GAS APPLIANCE AND VENT SYSTEM MUST BE VENTED DIRECTLY TO THE OUTSIDE OF THE BUILDING AND NEVER ATTACHED TO A CHIMNEY SERVING A SOLID FUEL OR GAS BURNING APPLI- ANCE. EACH DIRECT VENT GAS APPLIANCE MUST HAVE ITS OWN SEPARATE VENT SYSTEM. COM- MON VENT SYSTEMS ARE PROHIBITED.

•IF VENTING SYSTEM IS DISASSEMBLED FOR ANY REASON, REINSTALL PER THE INSTRUCTIONS

Vent Restriction

The GF 200 DV Lillehammer includes two draft restrictor plates found in the parts bag. These must be installed togethe within the stove in the follow- ing vent configurations:

1)ANY vertically vented installation

2)ANY horizontal vent utilizing a Snorkel Termination.

Additional restriction may be necessary, depending on the vent height.

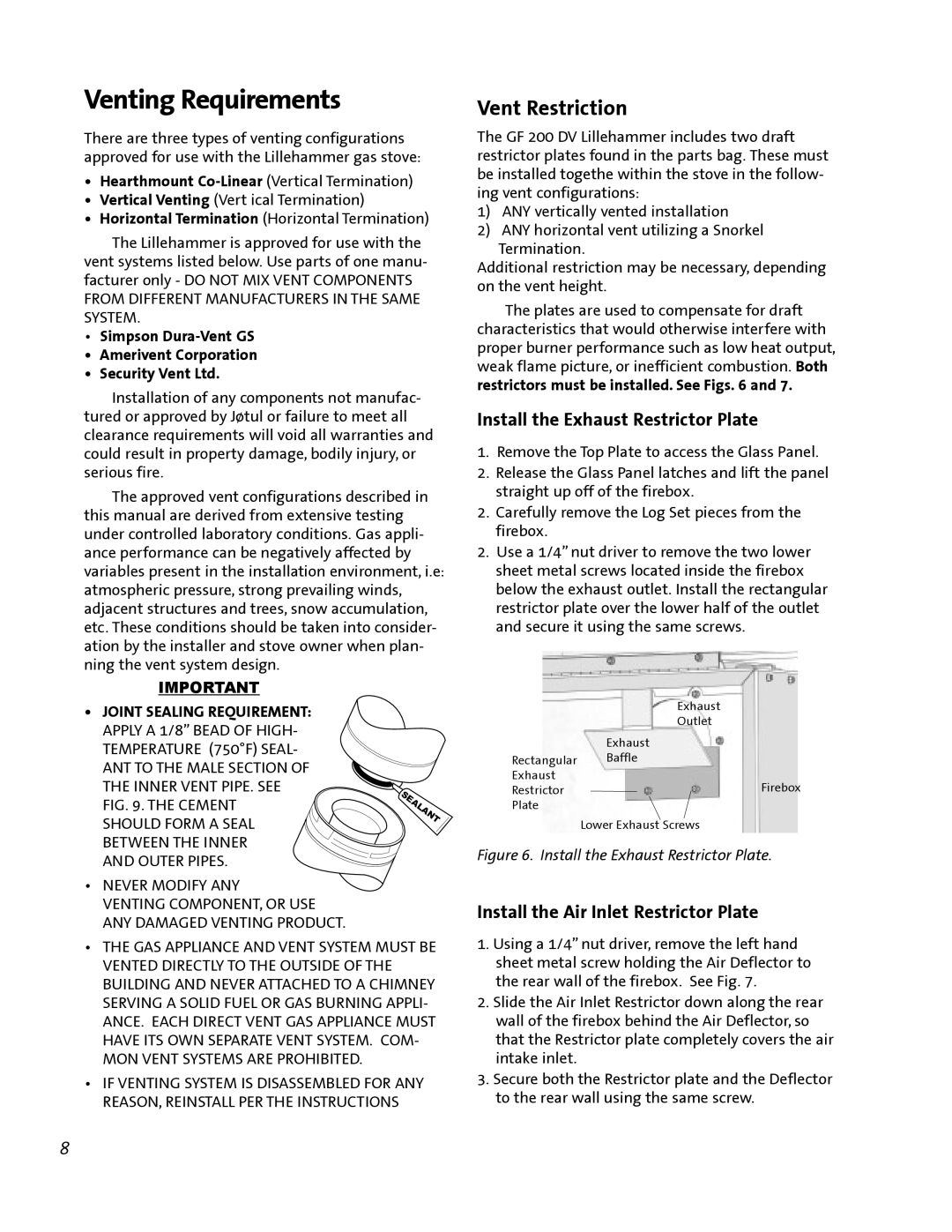

The plates are used to compensate for draft characteristics that would otherwise interfere with proper burner performance such as low heat output, weak flame picture, or inefficient combustion. Both restrictors must be installed. See Figs. 6 and 7.

Install the Exhaust Restrictor Plate

1.Remove the Top Plate to access the Glass Panel.

2.Release the Glass Panel latches and lift the panel straight up off of the firebox.

2.Carefully remove the Log Set pieces from the firebox.

2.Use a 1/4” nut driver to remove the two lower sheet metal screws located inside the firebox below the exhaust outlet. Install the rectangular restrictor plate over the lower half of the outlet and secure it using the same screws.

Exhaust

Outlet

Exhaust

Rectangular Baffle

Exhaust

RestrictorFirebox

Plate

Lower Exhaust Screws

Figure 6. Install the Exhaust Restrictor Plate.

Install the Air Inlet Restrictor Plate

1.Using a 1/4” nut driver, remove the left hand sheet metal screw holding the Air Deflector to the rear wall of the firebox. See Fig. 7.

2.Slide the Air Inlet Restrictor down along the rear wall of the firebox behind the Air Deflector, so that the Restrictor plate completely covers the air intake inlet.

3.Secure both the Restrictor plate and the Deflector to the rear wall using the same screw.

8