INSTALLATION AND CONNECTION

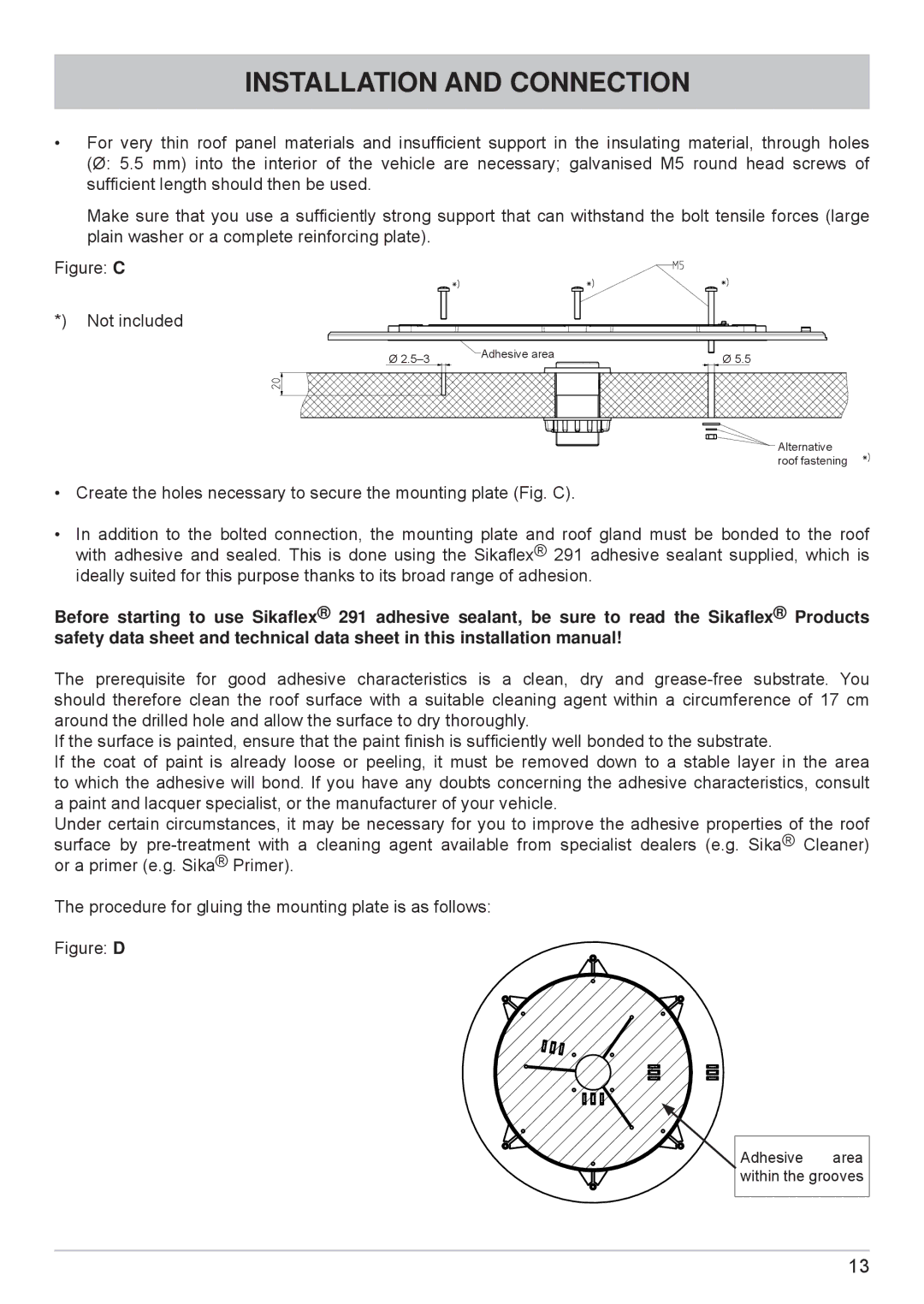

•For very thin roof panel materials and insufficient support in the insulating material, through holes (Ø: 5.5 mm) into the interior of the vehicle are necessary; galvanised M5 round head screws of sufficient length should then be used.

Make sure that you use a sufficiently strong support that can withstand the bolt tensile forces (large plain washer or a complete reinforcing plate).

Figure: C

*) Not included

Ø | Adhesive area | Ø 5.5 |

|

![]() Alternative roof fastening

Alternative roof fastening ![]()

•Create the holes necessary to secure the mounting plate (Fig. C).

•In addition to the bolted connection, the mounting plate and roof gland must be bonded to the roof with adhesive and sealed. This is done using the Sikaflex® 291 adhesive sealant supplied, which is ideally suited for this purpose thanks to its broad range of adhesion.

Before starting to use Sikaflex® 291 adhesive sealant, be sure to read the Sikaflex® Products safety data sheet and technical data sheet in this installation manual!

The prerequisite for good adhesive characteristics is a clean, dry and

If the surface is painted, ensure that the paint finish is sufficiently well bonded to the substrate.

If the coat of paint is already loose or peeling, it must be removed down to a stable layer in the area to which the adhesive will bond. If you have any doubts concerning the adhesive characteristics, consult a paint and lacquer specialist, or the manufacturer of your vehicle.

Under certain circumstances, it may be necessary for you to improve the adhesive properties of the roof surface by

The procedure for gluing the mounting plate is as follows:

Figure: D

Adhesive area within the grooves

13