Laserprinter

Operator’s Guide Kodak Professional RP 30 Laser Printer

Page

Table of Contents

Maintenance

Production

Regulatory and Safety Information

Contents

Regulatory Compliance

Hot Surface Symbol

Electrical Hazard Symbol

EMC Compliance CE Compliance

Laser Compliance and Safety

Mechanical Hazard Symbol

Operator’s Guide

Laser Source Label Locations of Laser Safety Labels

When Operating the Equipment

Safety Precautions

General Precautions

When Disposing of the Equipment

Handling of Processing Chemicals

Disposal of Chemicals and Containers

Skin and Eye Protection

Safety Precautions for the Handling of Chemicals

General Guidelines

Storage and Disposal

Warranty Repair Coverage

Warranty Information

Warranty Period

How to Obtain Service

Limitations

Introduction

Operator’s Guide Kodak Professional RP 30 Laser Printer

Text Styles

Using the Documentation

Structure

Indicates the potential for damage to or from the equipment

Storage of Chemicals and Paper

Consumable Storage Requirements

Overview

Info Printer Info Paper Processor

Components

Operator’s Guide

Product Description

Image Editing

Printing Sequence

Functional Procedure

Main Computer

Printer

Paper Processor

Sorter

Densitometer

Switching On the Equipment

Automatic Switch-On

Manual Switch-On

System Start

User Login

Readiness for Operation

Start Screen

Changing Users

End of Work

Touch Change user

Shutting Down

Automatic Shutdown

Manual Shutdown

Change Timer

Next Login

Touch Shutdown

Switching Off the Machine Partially Sleep Mode

Operating Controls

Button and Lamp on the Main Computer

Touch-screen Monitor

Keyboard and Mouse

Screen Structure

Information Area

Operator’s Guide

Touch-sensitive Buttons

Drop-down Menus

Pop-up Windows

Overview

Input Screen

Numeric Keypad

Menu Bar

Menu Overview

Main Menus

Print Mode Menu

Settings Menu without Machine Settings

Settings Menu with Machine Settings

Test Menu

End of Work Menu Status Information / Help Menus

Info

Additional Screens

Info Printer

Info Paper Processor

Info Order

Version Info

Error List

Help Index

Error Help Index

Help

Documentation

Chemicals

Operator’s Guide Kodak Professional RP 30 Laser Printer

Preparation of Chemicals

Rinsing the Tanks

Cold water after each preparation of a solution

Following order

Mixing the Tank Solutions

Bleach-Fix

Inserting the Chemical Filters

Developer

Tank Temperature ºC

Preparing Replenisher

See Paper Processor Settings in Chapter

Other Operations to be Performed Prior to Production Start

Machine Settings

Preparation of the Print Configuration Settings

From the Order Receipt to the Finished Print

When to Save Settings

Administrator

From the Order Receipt to the Finished Print

Operator

Preparation of the Print Configuration

Pfdf

Enter paper

Flie print

Page

Adjust shorter

Settings

Recover settings

Entering Names

Entering Numbers

Settings Machine settings

Machine Settings

Types of Settings

Configuration Surface and Paper settings

Machine

Install Software

Set date/time Other settings

Production balance

Settings Machine settings Surface New Select Pfdf surface

Defining Surfaces

Defining Paper Settings

Settings Machine settings Paper settings

Operator’s Guide

Paper Width Width Indicators Surface Indicators

Coding the Paper Magazine

Settings Machine settings Cut length

Defining Cut Lengths

User Interface

User Administrator Defining Users and User Rights

Settings Machine settings User manager

− Edit

− Password, Repeat

− Language, Keyboard, Preview frequency, Beep touch

Rights Button Description

Configurations

− User rights

Preview

Startup Defining the Start Time / Standard User Timer

Settings Machine settings Startup Edit calendar

Calendar Defining Off Days

Installing the Software

Settings Machine settings Install software

Printer Settings

Paper Processor Settings

Settings Machine settings PP replenishment

Settings Machine settings Productions Balance Digital

Production Balance Digital

Settings

Impact

Sharpening

Sharpness of Edges

Shifting towards +

Soft-focus effect

Unsharpness

Sharpness of Grain

Fine structuring

Detail Contrast

Remote Order File Print

Digital Order Settings

Settings Machine settings Network orders

Resource name

Computer name

Remote Order Autosave

Automatic printing On/Off

Address or name Name or IP address

Other Settings

Max. PpF

DTFS Preselection

Print Configurations

Settings Print configurations

Paper Backprint Correction AutoSave Front print Order

Creating a New Configuration

Creating, Editing, and Deleting Configurations

Creating a New Configuration Based on an Existing One

Editing a Configuration

Deleting a Configuration

Creating a Paper Configuration

Paper Configurations

Settings Print configurations Paper New or Edit

Select from the Paper Settings and the Paper Surfaces

Touch Save or Save as

Backprint Configurations

Select Save or Save as

Operator’s Guide

Correction Configurations

Settings Print configurations Corrections New or Edit

Operator’s Guide

Autosave Configurations

Settings Print configurations Autosave New or Edit

Drive

Autosave fixed File format

Quantity

Resolution

Autosave quality File format

Resolution and File format as in Autosave quality

CD, Internet Upload, Normal

Front Print Configurations

Select Save or Save as

Order Configurations

Package

Single

Reproduction

Specify Paper configuration and Cut length

Creating a Single Configuration

Select Film mask File print

Select Configurations

Creating a Package Configuration

Set the Configuration type to Package

Select Film mask and Film type

Reproduction

Configuration Types in the Order Configuration List

Black-and-White and Sepia Prints

Defining a Configuration as the Standard Configuration

Procedure

Saving and Loading Settings and Configurations

When to Save Settings

Settings Save settings

Load Settings

Settings Load settings

Tests

Operator’s Guide Kodak Professional RP 30 Laser Printer

Printer Tests

Introduction

Overview

Printing a PBL Test

Prerequisites for MBL and PBL Calibration

Test Start PBL

PBL Test with Laser Point

Printing an MBL Test

Test Start MBL

See Save/Load Settings and Configurations in , Settings

Daily Calibration With the MBL

Daily Calibration Without the MBL

Calibration of New Paper, Emulsion Changes Master Paper

Completion of the New Calibration

Testing the Paper Processor

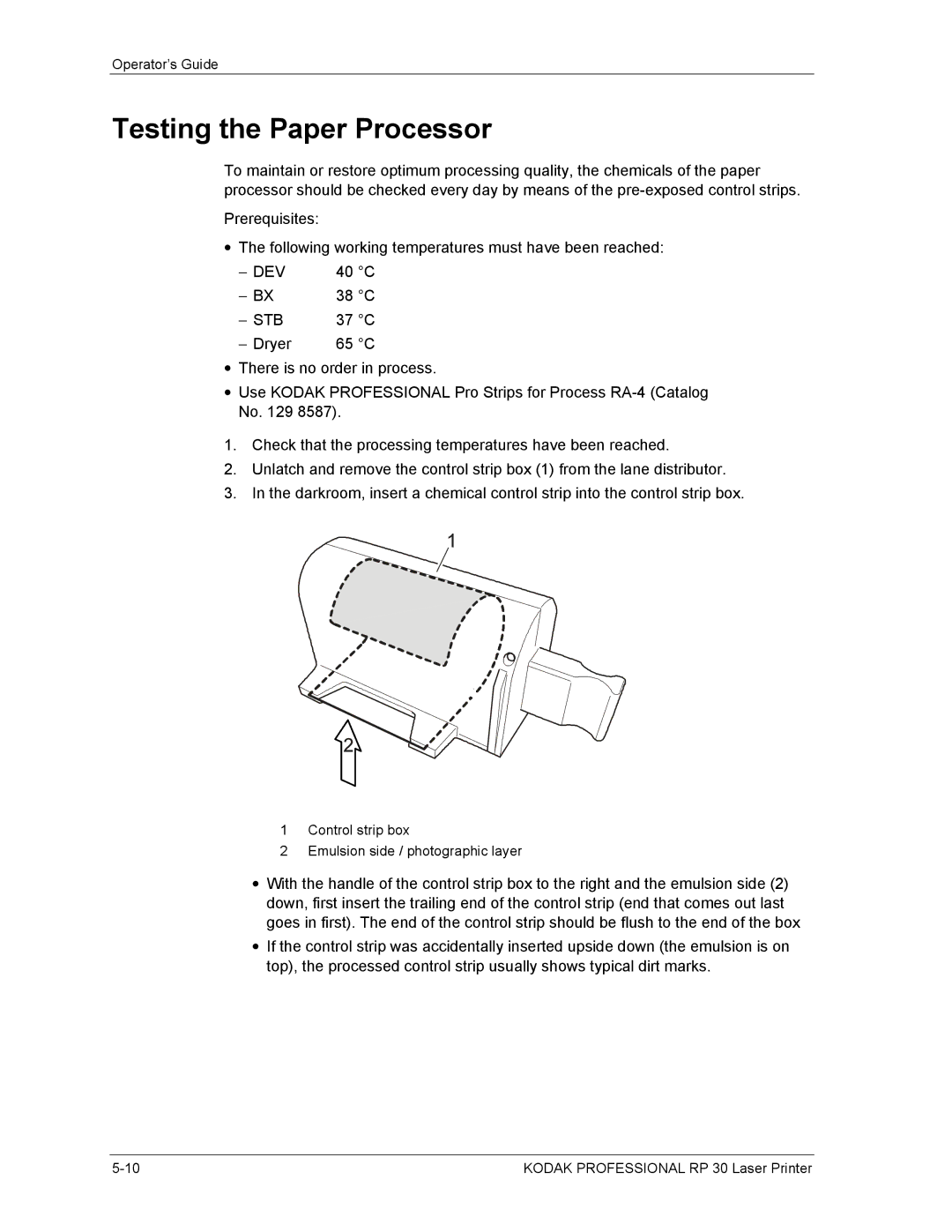

Test Control strip Chemical control strip

Operator’s Guide Kodak Professional RP 30 Laser Printer

Production

Operator-Controlled Start

Preparing the Equipment for Different Orders

Preparing the Paper Magazine

Operator’s Guide

Putting Paper in the Magazine

Important Avoid fogging of the leading paper edge

Chapter

Paper Widths Not Yet Coded

Changing the Paper Magazine

Manual Order Number

Order Processing

Order Number Automatic / Manual

Automatic Order Number

End of Order Automatic / Manual

Print Modes

Printing File Print

Prerequisites

DTFS

Selecting the Configuration Type for an Order

Single or Package

Reproduction

Using Autosave to Save Processed Images without Printing

Black-and-White or Sepia Prints

Changing the Current Configuration

Changing the Configuration and the Order Number

With Change Config

Under Machine settings / Other settings

Selecting a Different Configuration

Changing the Order Number

Loading Image Files from Data Carriers

Touch Start print or Save order

Loading Saved Digital Orders

Saving Digital Orders

Touch Save order

Touch Finish order

Printing File Prints without Preview

Touch Start print

Touch Prepare order

Printing File Prints with Preview

Image Editing and Special in All Print Modes with Preview

Touch Enter text

Special Text

Image Improvement

Touch Format text. a new screen opens

Saving Processed Images as Files

Select File format, Resolution, and the Drive symbol

Images in the Network

Network Orders

Print mode Network orders

Operator-Controlled Start

Automatic Start

Finishing Print Orders

Printing Network Orders

Correcting System Conditions

Operator’s Guide Kodak Professional RP 30 Laser Printer

Avoiding Handling Errors

System Errors

Error Messages

Reset with the on Button or Stop Button on the Screen

Gray Screen After Reset

Error Handling

Unresolved Errors

General

Fill print

Image Processing Errors

Paper Processor Errors

Fit image to paper

Help in Case of Error Messages

Printer Errors

Other Error Situations

Shutter not reached MR, ML SGLS01 not reached

Removing Paper Jams

Belts, sharp corners, and sharp edges in the printer area

Paper Jam in the Printer Section

Paper Jam in the Transport Unit

Before pulling out the transport unit

Paper Transport at the Bottom

Paper Transport at the Top

Sheet Bridge to Transport Unit

Operator’s Guide

Correcting System Conditions

Paper Jam in the Print Engine

Correcting System Conditions

Operator’s Guide

Paper Jam in the Lane Distributor

Paper Jam between the Lane Distributor and Sheet Transfer

Mechanical damage cannot be ruled out

Paper Jam in the Paper Processor

Chemical splashes may stain the covers. Use the splash guard

Or remove splashes immediately with water

Maintenance

Other Consumables Kodak Professional Digital III Paper

Daily Weekly Monthly

Maintenance Schedule and Maintenance Intervals

Maintenance jobs to be performed by the customer

Required

Daily Maintenance

Performing a Process Control for the Paper Processor

Maintenance

Weekly Maintenance

Removing Paper Dust from the Printer Sections

Single Sheet Buffer and Sheet Bridge

Print Engine

Maintenance

Important Make sure that the transport belts are not shifted

Lane Distributor

May run in the marked area

Sheet Transfer

Water over the weekend

Stack the crossovers

Removing the CD Color Developer Feed Unit

Removing the Tank Crossovers

Cleaning

Removing the V Wiper and Squeegee Unit

Damage

Checking the Solution Levels

Cleaning the Chemical Filters

Cleaning the Filters in Astor and Water Inlets

Cleaning the Densitometer Calibration Plate

Plates

Cleaning the Transport Belt of the Print Chute

Settings Machine settings PP temperature

Monthly Maintenance

Checking the Solution Temperatures

Touch Readjust

Door to Print Engine

Cleaning / Replacing the Air Filters

Them

Into the print engine

Operator’s Guide Kodak Professional RP 30 Laser Printer

Maintenance

Procedure

Changing Chemical Filters

Cleaning the Processing Racks

Operator’s Guide

Maintenance

Balance in order to prevent a paper jam

Cleaning the Dryer Rack

Weekend, be sure to deactivate the automatic MBL Master

On Monday before starting to work, wipe off all deposits on

Maintenance

Cleaning the Paper

Cleaning / Replacing the Air Filters

Cleaning the Guide with the Feed Chute

Operator’s Guide

Maintenance

Operator’s Guide

Maintenance When Required

Changing the Ink Ribbon on the Back Printer

Emptying the Effluent Tanks

Tanks is 20 L

Air Filters

Consumables

Chemicals

Other Consumables

Kodak Professional Digital III Paper

Rolls Surface Catalog No

Page

Page

Eastman Kodak Company

![]() 2

2![]()