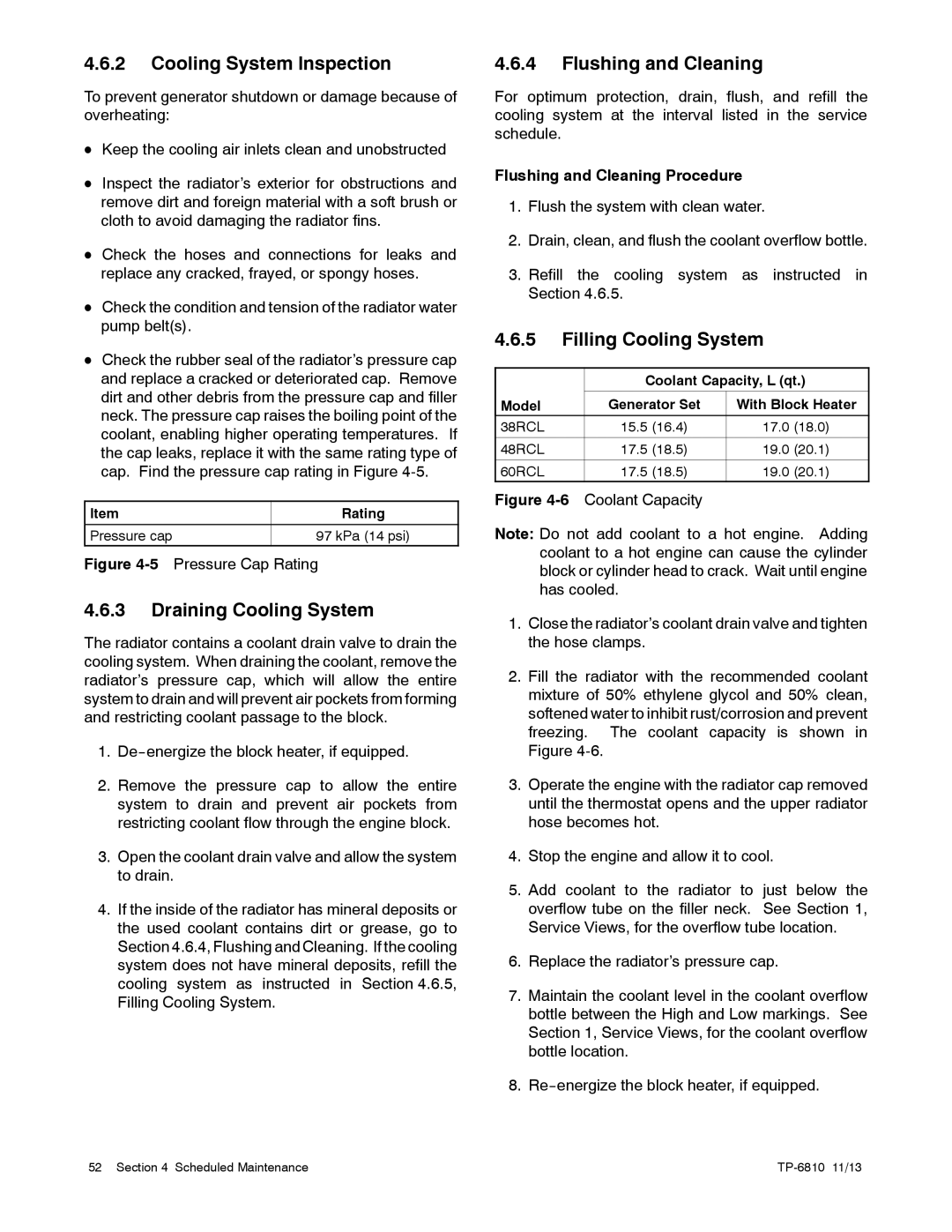

38RCL, 48RCL, 60RCL specifications

The Kohler RCL series of generators, particularly the 60RCL, 48RCL, and 38RCL models, represents a premium choice for those seeking reliable power solutions for residential and light commercial applications. Each model is tailored to meet diverse power needs, ensuring uninterrupted electricity supply during outages.The 60RCL is engineered for maximum performance, offering 60 kW of power. This model is ideal for larger homes or small businesses that require dependable backup power. Its powerful Kohler engine is designed to deliver a quiet, smooth performance, while the advanced sound-dampening features keep noise levels to a minimum. The 48RCL offers a slightly lower output at 48 kW, making it suitable for medium-sized homes. Its compact design allows for flexible installation options, whether it’s outdoors or in a utility area, while still providing robust power during critical times.

The 38RCL, while the smallest of the series with 38 kW output, is perfect for homes that need a reliable backup generator without the bulk. Its streamlined design does not compromise on performance, making it an excellent choice for energy-efficient homes. All models in the RCL series come equipped with Kohler's Command Pro commercial-grade engine, ensuring longevity and reliability even in the harshest conditions.

A standout feature of the RCL series is the integrated KOHLER® 2.4-inch color display, which allows users to monitor generator performance in real-time. This user-friendly interface provides vital information such as operational status, run time, and maintenance notifications. Additionally, the series is designed with automatic transfer switches that allow for seamless switching between utility and generator power.

Moreover, these generators incorporate advanced control systems with remote monitoring capabilities, enabling users to check the status of their power supply from a smartphone or tablet. Designed with efficiency in mind, the RCL series boasts a fuel-efficient operation that supports both natural gas and propane, catering to diverse energy preferences.

In summary, the Kohler 60RCL, 48RCL, and 38RCL generators combine high performance, advanced technology, and user-friendly features. They are reliable solutions for anyone looking to safeguard their power needs, ensuring peace of mind when it matters most.