Safety inspection guide

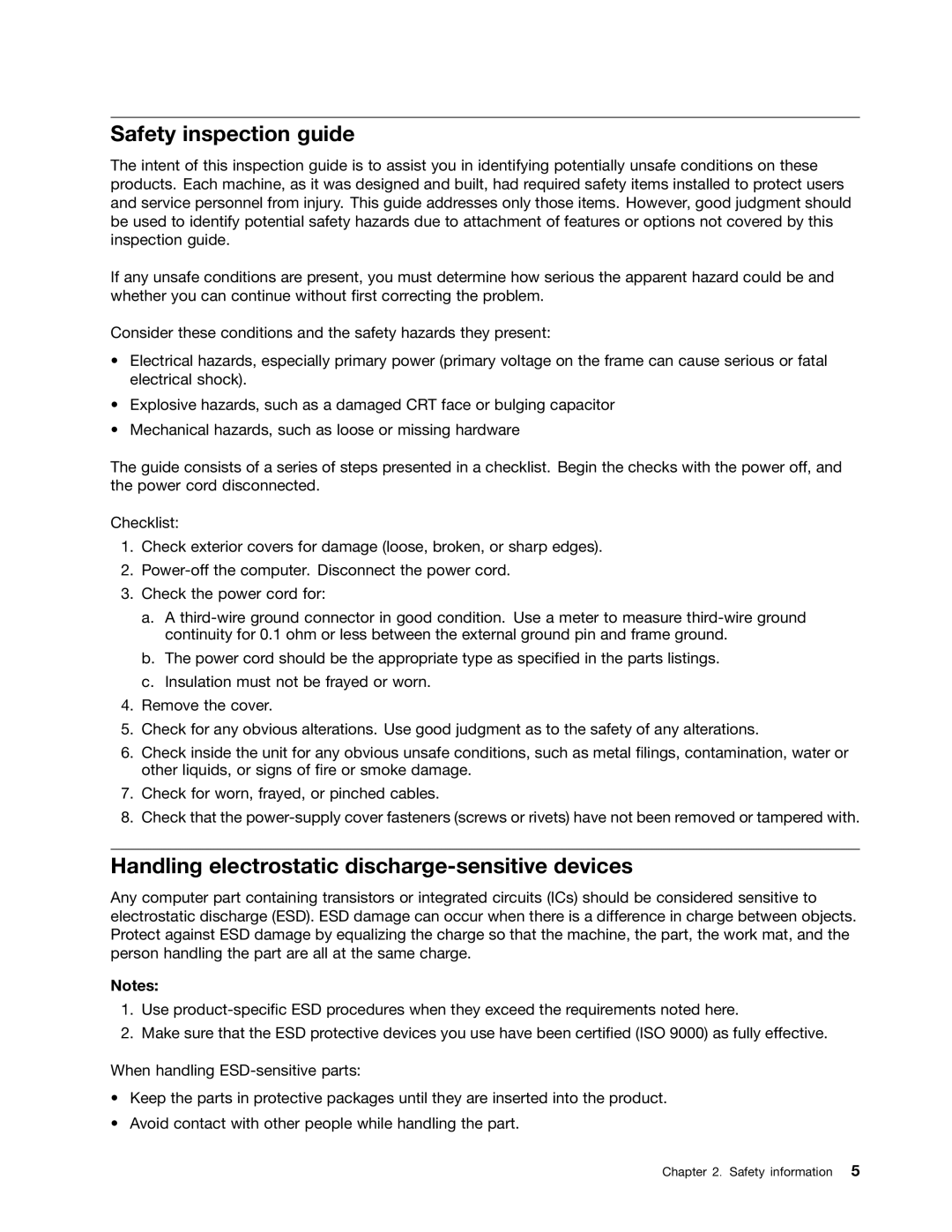

The intent of this inspection guide is to assist you in identifying potentially unsafe conditions on these products. Each machine, as it was designed and built, had required safety items installed to protect users and service personnel from injury. This guide addresses only those items. However, good judgment should be used to identify potential safety hazards due to attachment of features or options not covered by this inspection guide.

If any unsafe conditions are present, you must determine how serious the apparent hazard could be and whether you can continue without first correcting the problem.

Consider these conditions and the safety hazards they present:

•Electrical hazards, especially primary power (primary voltage on the frame can cause serious or fatal electrical shock).

•Explosive hazards, such as a damaged CRT face or bulging capacitor

•Mechanical hazards, such as loose or missing hardware

The guide consists of a series of steps presented in a checklist. Begin the checks with the power off, and the power cord disconnected.

Checklist:

1.Check exterior covers for damage (loose, broken, or sharp edges).

2.

3.Check the power cord for:

a.A

b.The power cord should be the appropriate type as specified in the parts listings.

c.Insulation must not be frayed or worn.

4.Remove the cover.

5.Check for any obvious alterations. Use good judgment as to the safety of any alterations.

6.Check inside the unit for any obvious unsafe conditions, such as metal filings, contamination, water or other liquids, or signs of fire or smoke damage.

7.Check for worn, frayed, or pinched cables.

8.Check that the

Handling electrostatic discharge-sensitive devices

Any computer part containing transistors or integrated circuits (ICs) should be considered sensitive to electrostatic discharge (ESD). ESD damage can occur when there is a difference in charge between objects. Protect against ESD damage by equalizing the charge so that the machine, the part, the work mat, and the person handling the part are all at the same charge.

Notes:

1.Use

2.Make sure that the ESD protective devices you use have been certified (ISO 9000) as fully effective.

When handling

•Keep the parts in protective packages until they are inserted into the product.

•Avoid contact with other people while handling the part.

Chapter 2. Safety information 5