KEY

Table of Contents

Summary

Front

Rear

Indicator Panel

VCR Function Indication

Terminal Signal Levels

IN/OUT Description

Summary Critical Parts Replacing Time Table

Cabinet & Main Frame Exploded Views

Cabinet & Main Frame Section Parts list

Cabinet and Main Frame Section

Packing Accessory Section Parts list

Packing & Accessory Section

PG Adjustment

Connection chart of PG adjustment

Power CircuitSMPS No 5.3 a

No 24

No 5.2 a to AVCP, Bias

Video is unstable in PB mode

PB mode

When the drum moter stop

Servo Circuit

When the capstan motor stops

Capstan motor stops

C Circuit

No Video in EE Mode

No Video in EE Mode

Clean the Drum Check the System Circuit IC501 Pin

Pin 16, 40, 55, 58, 87?

Is the EE signal normal?

Is 5V applied to the IC301 Pin 16, 40, 55, 58, 87?

No sound in EE Mode No sound in PB Mode

No sound in EE Mode

No sound in PB Mode

Audio Circuit

No sound in REC Mode

No sound in REC Mode

Auto Stop

SYSTEM/KEY Circuit Auto Stop

No cassette tape loading

No Key display

OSD Circuit

No OSD display

No F.OSD display

Electrical Block & Circuit Diagrams

Power Block Diagram

Power Clrcuit Diagram

Audio Block Diagram

C Block Diagram

V Circuit Diagram

Electrical Block & Circuit Diagrams

System Block Diagram

Electrical Block & Circuit Diagrams

System Clrcuit Diagram

Jack Clrcuit Diagram

KEY-BOARDCLRCUIT Diagram

Electrical Printed Circuit Diagrams

KEY 1 P.C.BOARD KEY 2 P.C.BOARD

Jack P.C.BOARD

Mechanism

Top View Bottom View

Part Fixing Type

Drum Assembly Fig. A-1-1

Drum Motor

Plate Top Fig. A-2-1

Fig. A-2-4

Gear Assembly Rack F/L Fig. A-2-5

Holder Assembly CST Fig.A-2-2

Bracket Assembly L/D Motor Fig. A-2-4

Arm Assembly F/L Fig. A-2-6

Arm Assembly

Cleaner

Base Assembly A/C Head

Head F/E Fig. A-3-2

Brake Assembly T Fig. A-4-1

Brake Assembly RS Fig. A-4-2

Arm Assembly Tension Fig. A-4-3

Reel S / Reel T Fig. A-4-4

Lever T/up Fig. A-5-4 Arm T/up Fig. A-5-5

Arm Assembly Pinch Fig. A-5-3

Opener Lid Fig. A-5-2

Brake Assembly Capstan

Lever F/R Fig. A-6-3

Gear Sector Fig. A-7-3

Lever Tension Fig. A-7-5

Lever Spring Fig. A-7-6

Just lift the Plate Slider up

Gear Assembly P2 Fig. A-8-1/ Gear Assembly P3 Fig. A-8-2

Base Assembly P2 Fig. A-8-3/ Base Assembly P3 Fig. A-8-4

Base Loading Fig. A-9-1 Arm Assembly Idler Fig. A-9-3

Arm Assembly Idler

Base Tension Fig. A-9-2

Base Tension Base Loading

Deck Mechanism Adjustment

Mechanism Alignment Position Check

Fig. C-1

Checking Torque

Test Equipment/ Fixture Test Conditions

Mechanism Condition

Torque Gauge 600g.cm ATG Cassette Torque Meter SRK-VHT-303

Guide Roller Height Adjustment

Audio/Control A/C Head Adjustment

Adjustment Procedure/Diagrams

Head Assembly

Head Base

Value Adjustment

Precise Adjustment Azimuth adjustment

Adjustment Procedure Adjustment Diagram

1KHZ 7KHZ

Adjustment after Replacing Drum Assembly Video Heads

Check the Tape Travel after Reassembling Deck Assembly

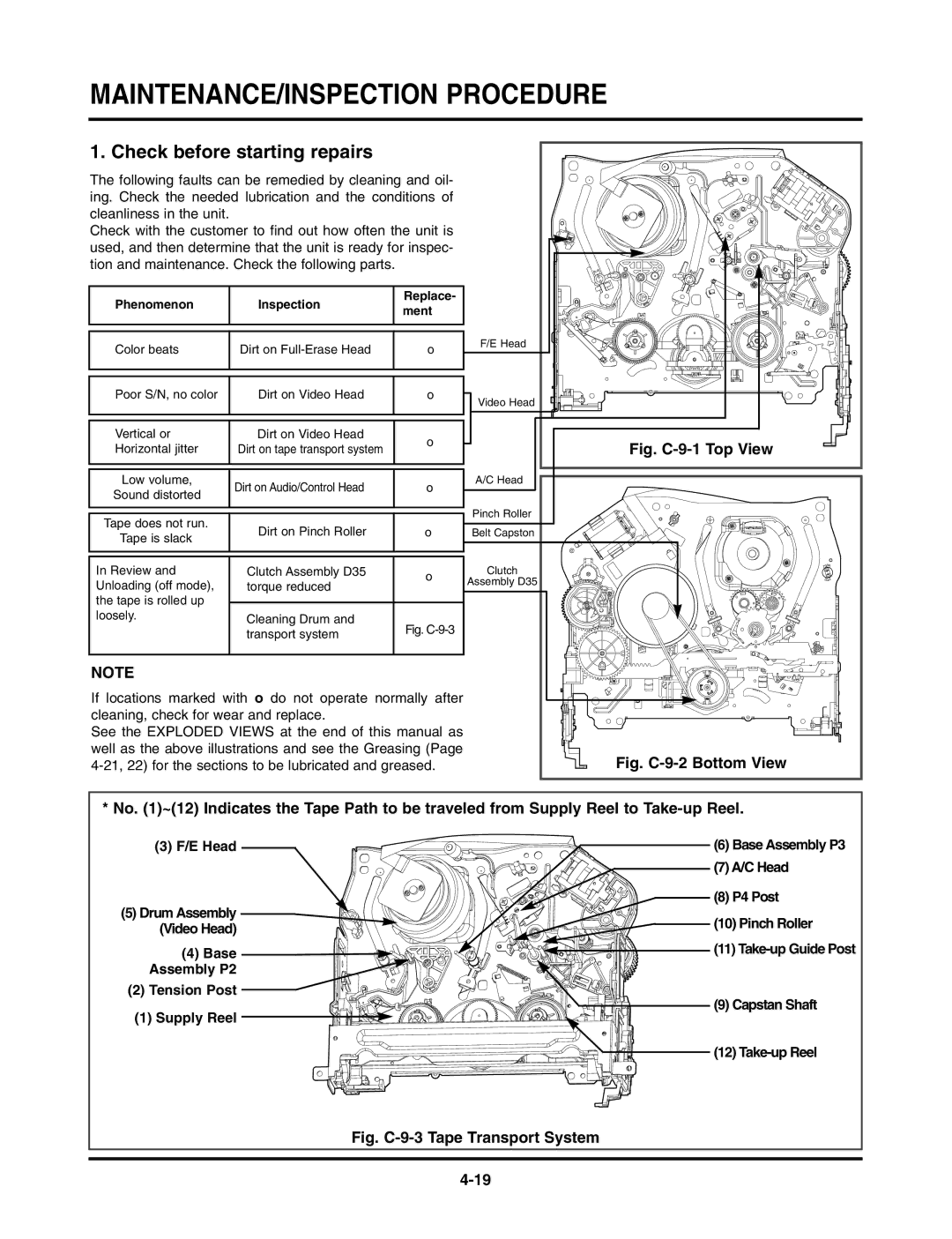

Check before starting repairs

Required Maintenance

Scheduled Maintenance

Maintenance Procedure

Cleaning

Gear Sector Gear Cam Base Loading Gear Drive

Greasing

Chassis Bottom Chassis Top

Base, Tension

Lever, F/R, Base, Tension

Gear AY, P2 & P3

Mechanism Troubleshooting Guide

Auto Stop PLAY/CUE/REV

Nono

Is the Belt ok?

Front Loading Mechanism

Cassette does not load

Exploded Views

Moving Mechanism

A11

Parts Section

NSP Not Service Part

RUN Date

Description Specification

Assembly Section Remarks

LOCA.NO Description Specification Remarks

Screw

LOCA.NO Description Specification Remark BATTERY,LITHIUM

Electrecal section

Buzzer

Capacitor

LOCA.NO Description Specification Remark

NP0 TS

Coil

Diode

Digitron

Filter

Fuse

Holder

R121 0RD1800F608

R3G6 0RD1800F608

R553 0RD2200F608

R610 0RD2701F608

LOCA.NO Description Specification

Remote Controller Receiver Remark

Switch

RESISTOR,DRAWING

Transformer

Varistor

TAL

Zener Diode