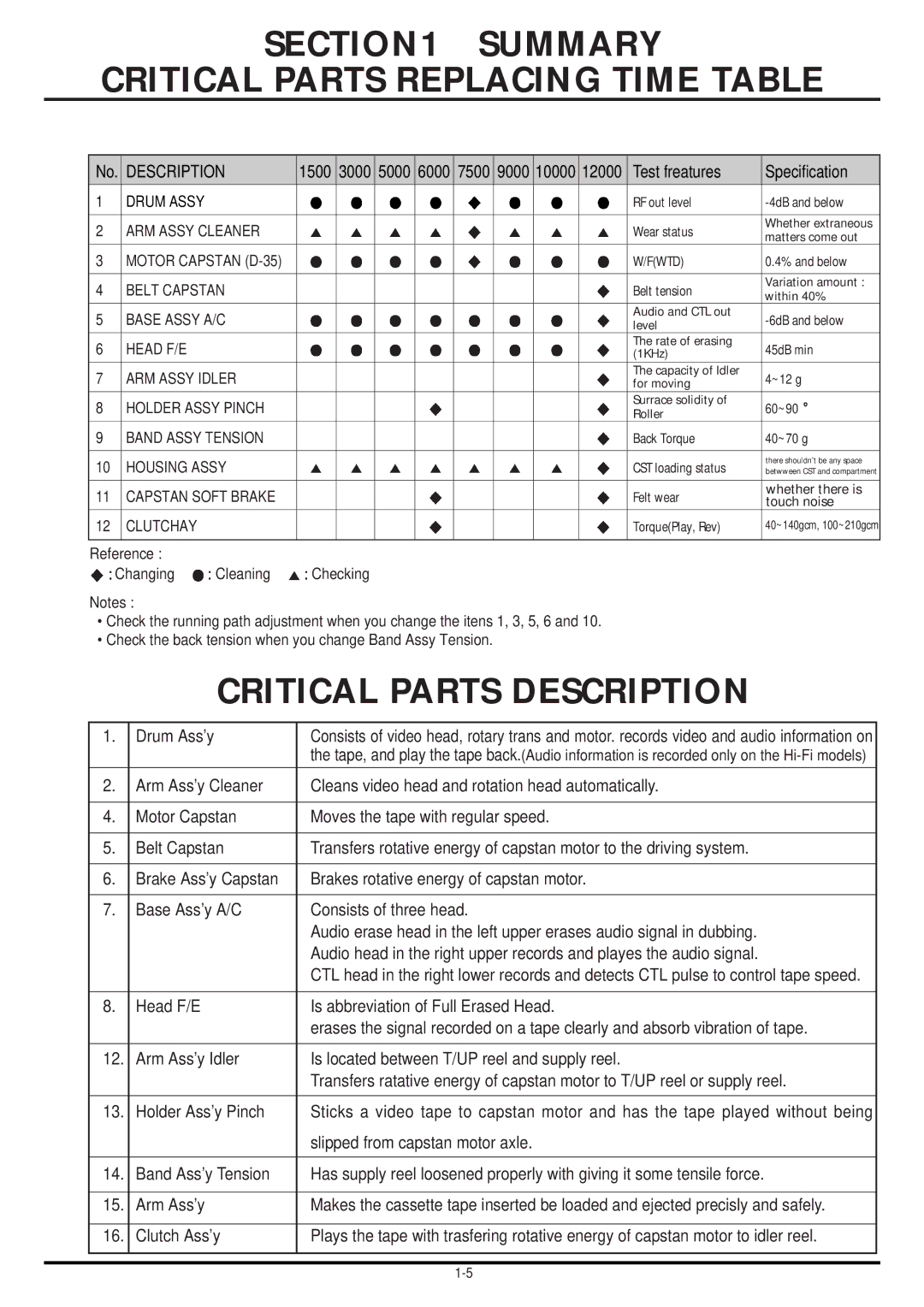

SECTION1 SUMMARY

CRITICAL PARTS REPLACING TIME TABLE

No. | DESCRIPTION | 1500 | 3000 | 5000 | 6000 | 7500 | 9000 | 10000 | 12000 | Test freatures | Specification | |

1 | DRUM ASSY |

|

|

|

|

|

|

|

|

| RF out level | |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 | ARM ASSY CLEANER |

|

|

|

|

|

|

|

| Wear status | Whether extraneous | |

|

|

|

|

|

|

|

| matters come out | ||||

|

|

|

|

|

|

|

|

|

|

|

| |

3 | MOTOR CAPSTAN |

|

|

|

|

|

|

|

| W/F(WTD) | 0.4% and below | |

|

|

|

|

|

|

|

|

|

|

|

|

|

4 | BELT CAPSTAN |

|

|

|

|

|

|

|

| Belt tension | Variation amount : | |

|

|

|

|

|

|

|

| within 40% | ||||

|

|

|

|

|

|

|

|

|

|

|

| |

5 | BASE ASSY A/C |

|

|

|

|

|

|

|

| Audio and CTL out | ||

|

|

|

|

|

|

|

| level | ||||

6 | HEAD F/E |

|

|

|

|

|

|

|

|

| The rate of erasing | 45dB min |

|

|

|

|

|

|

|

|

| (1KHz) | |||

7 | ARM ASSY IDLER |

|

|

|

|

|

|

|

| The capacity of ldler | 4~12 g | |

|

|

|

|

|

|

|

| for moving | ||||

8 | HOLDER ASSY PINCH |

|

|

|

|

|

|

|

| Surrace solidity of | 60~90 | |

|

|

|

|

|

|

|

| Roller | ||||

9 | BAND ASSY TENSION |

|

|

|

|

|

|

|

| Back Torque | 40~70 g | |

|

|

|

|

|

|

|

|

|

|

|

|

|

10 | HOUSING ASSY |

|

|

|

|

|

|

|

| CST loading status | there shouldn’t be any space | |

|

|

|

|

|

|

|

| betwween CST and compartment | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

11 | CAPSTAN SOFT BRAKE |

|

|

|

|

|

|

|

| Felt wear | whether there is | |

|

|

|

|

|

|

|

| touch noise | ||||

12 | CLUTCHAY |

|

|

|

|

|

|

|

|

| Torque(Play, Rev) | 40~140gcm, 100~210gcm |

|

|

|

|

|

|

|

|

|

|

|

|

|

Reference : |

|

|

|

|

|

|

|

|

|

|

| |

Changing | Cleaning | Checking |

| |||||||||

Notes :

•Check the running path adjustment when you change the itens 1, 3, 5, 6 and 10.

•Check the back tension when you change Band Assy Tension.

CRITICAL PARTS DESCRIPTION

| 1. | Drum Ass’y | Consists of video head, rotary trans and motor. records video and audio information on |

|

|

|

| the tape, and play the tape back.(Audio information is recorded only on the |

|

|

|

|

|

|

| 2. | Arm Ass’y Cleaner | Cleans video head and rotation head automatically. |

|

|

|

|

|

|

| 4. | Motor Capstan | Moves the tape with regular speed. |

|

|

|

|

|

|

| 5. | Belt Capstan | Transfers rotative energy of capstan motor to the driving system. |

|

|

|

|

|

|

| 6. | Brake Ass’y Capstan | Brakes rotative energy of capstan motor. |

|

|

|

|

|

|

| 7. | Base Ass’y A/C | Consists of three head. |

|

|

|

| Audio erase head in the left upper erases audio signal in dubbing. |

|

|

|

| Audio head in the right upper records and playes the audio signal. |

|

|

|

| CTL head in the right lower records and detects CTL pulse to control tape speed. |

|

|

|

|

|

|

| 8. | Head F/E | Is abbreviation of Full Erased Head. |

|

|

|

| erases the signal recorded on a tape clearly and absorb vibration of tape. |

|

|

|

|

|

|

| 12. | Arm Ass’y Idler | Is located between T/UP reel and supply reel. |

|

|

|

| Transfers ratative energy of capstan motor to T/UP reel or supply reel. |

|

|

|

|

|

|

| 13. | Holder Ass’y Pinch | Sticks a video tape to capstan motor and has the tape played without being |

|

|

|

| slipped from capstan motor axle. |

|

|

|

|

|

|

| 14. | Band Ass’y Tension | Has supply reel loosened properly with giving it some tensile force. |

|

|

|

|

|

|

| 15. | Arm Ass’y | Makes the cassette tape inserted be loaded and ejected precisly and safely. |

|

|

|

|

|

|

| 16. | Clutch Ass’y | Plays the tape with trasfering rotative energy of capstan motor to idler reel. |

|

|

|

|

|

|

|

|

|

|

|