OPERATION | ||

|

|

|

TYPICAL FUEL CONSUMPTION

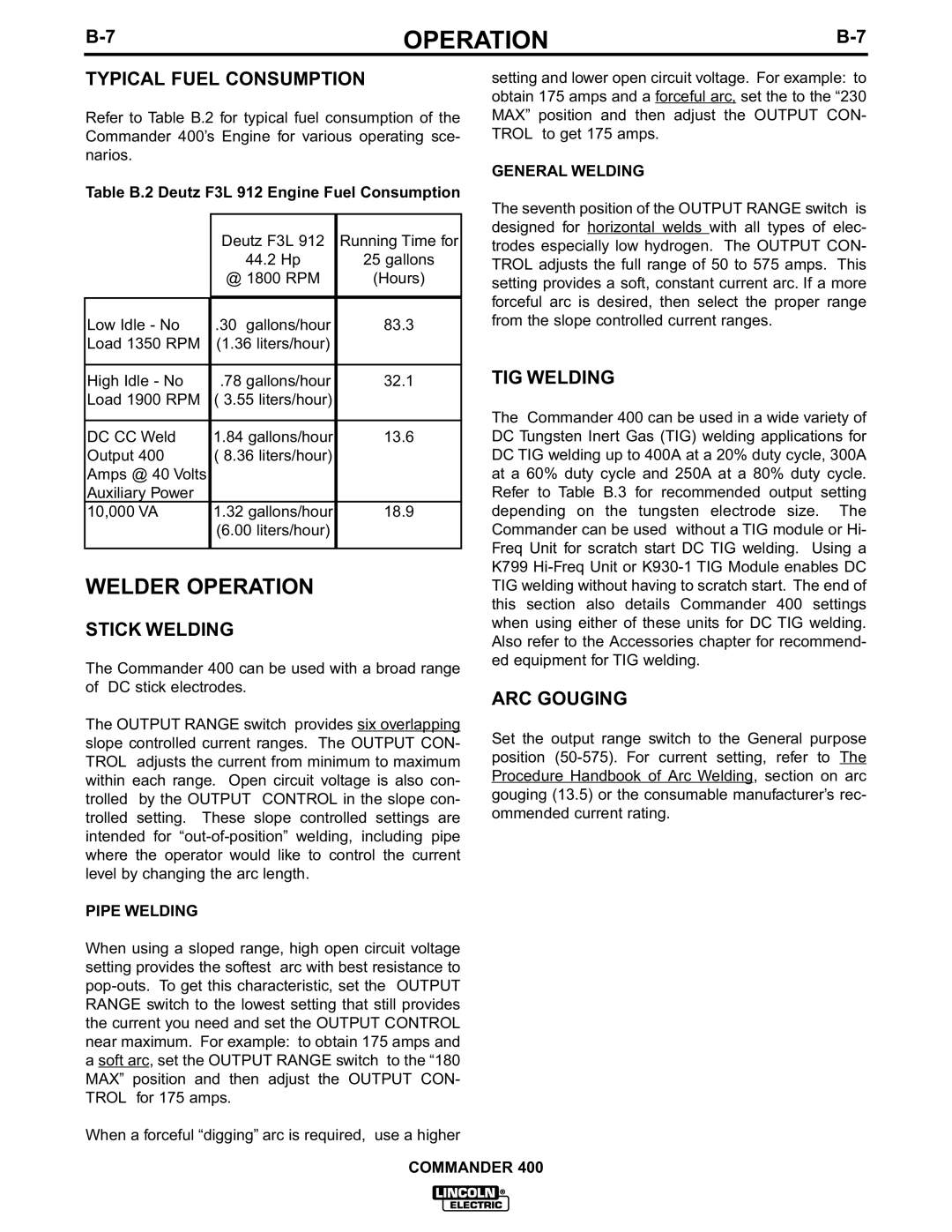

Refer to Table B.2 for typical fuel consumption of the Commander 400’s Engine for various operating sce- narios.

Table B.2 Deutz F3L 912 Engine Fuel Consumption

| Deutz F3L 912 | Running Time for |

| 44.2 Hp | 25 gallons |

| @ 1800 RPM | (Hours) |

|

|

|

Low Idle - No | .30 gallons/hour | 83.3 |

Load 1350 RPM | (1.36 liters/hour) |

|

|

|

|

High Idle - No | .78 gallons/hour | 32.1 |

Load 1900 RPM | ( 3.55 liters/hour) |

|

|

|

|

DC CC Weld | 1.84 gallons/hour | 13.6 |

Output 400 | ( 8.36 liters/hour) |

|

Amps @ 40 Volts |

|

|

Auxiliary Power |

|

|

10,000 VA | 1.32 gallons/hour | 18.9 |

| (6.00 liters/hour) |

|

|

|

|

WELDER OPERATION

STICK WELDING

The Commander 400 can be used with a broad range of DC stick electrodes.

The OUTPUT RANGE switch provides six overlapping slope controlled current ranges. The OUTPUT CON- TROL adjusts the current from minimum to maximum within each range. Open circuit voltage is also con- trolled by the OUTPUT CONTROL in the slope con- trolled setting. These slope controlled settings are intended for

setting and lower open circuit voltage. For example: to obtain 175 amps and a forceful arc, set the to the “230 MAX” position and then adjust the OUTPUT CON- TROL to get 175 amps.

GENERAL WELDING

The seventh position of the OUTPUT RANGE switch is designed for horizontal welds with all types of elec- trodes especially low hydrogen. The OUTPUT CON- TROL adjusts the full range of 50 to 575 amps. This setting provides a soft, constant current arc. If a more forceful arc is desired, then select the proper range from the slope controlled current ranges.

TIG WELDING

The Commander 400 can be used in a wide variety of DC Tungsten Inert Gas (TIG) welding applications for DC TIG welding up to 400A at a 20% duty cycle, 300A at a 60% duty cycle and 250A at a 80% duty cycle. Refer to Table B.3 for recommended output setting depending on the tungsten electrode size. The Commander can be used without a TIG module or Hi- Freq Unit for scratch start DC TIG welding. Using a K799

ARC GOUGING

Set the output range switch to the General purpose position

PIPE WELDING

When using a sloped range, high open circuit voltage setting provides the softest arc with best resistance to

When a forceful “digging” arc is required, use a higher

COMMANDER 400