OPERATION | ||

|

|

|

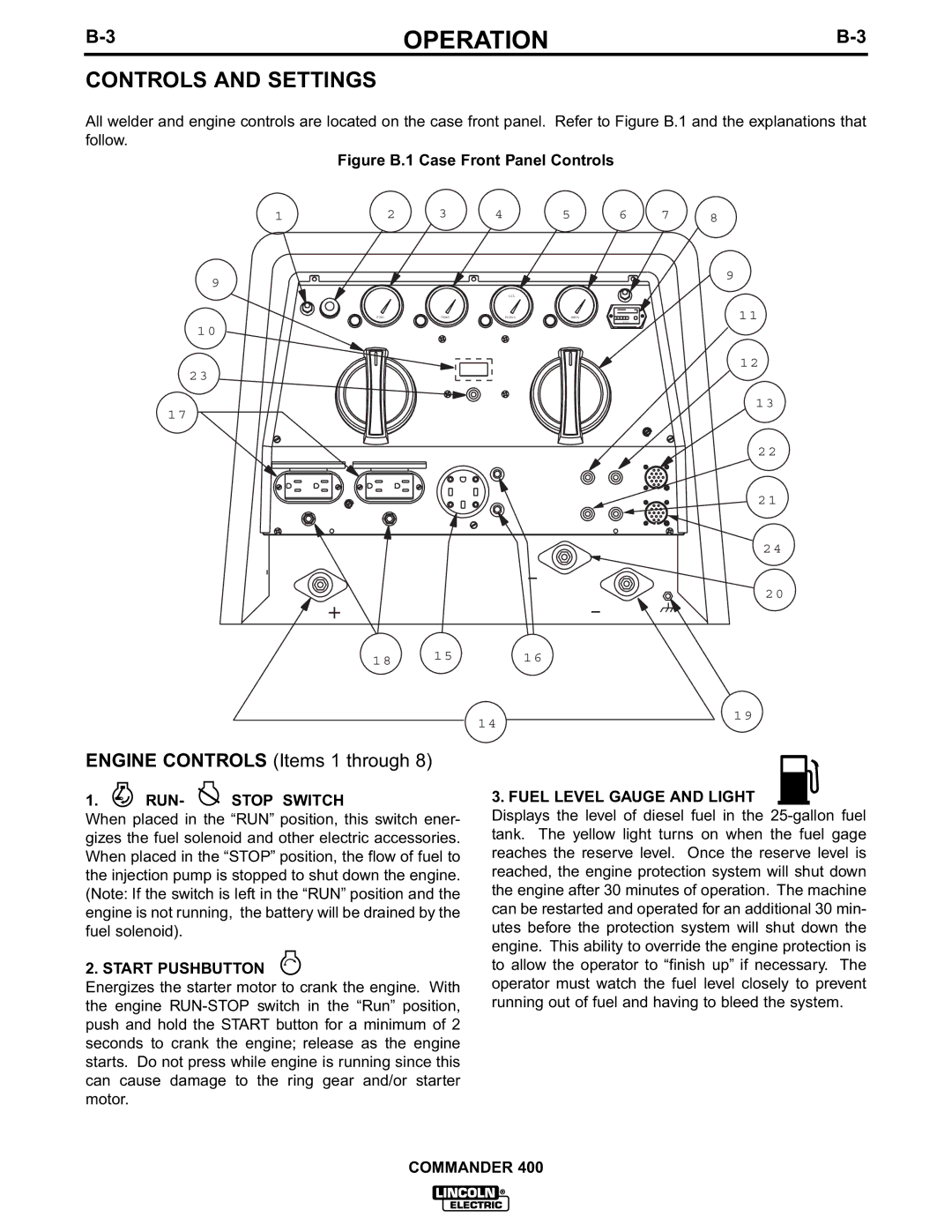

CONTROLS AND SETTINGS

All welder and engine controls are located on the case front panel. Refer to Figure B.1 and the explanations that follow.

Figure B.1 Case Front Panel Controls

1 | 2 | 3 | 4 | 5 | 6 | 7 |

9

|

| OIL |

|

|

|

FUEL | TEMP | PRESS | AMPS | 0 0 0 0 0 | 0 |

|

|

|

| H O U R S |

|

1 0

2 3

1 7

|

| - |

+ |

| - |

1 8 | 1 5 | 1 6 |

|

| 1 4 |

8

9

11

12

1 3

2 2

2 1

2 4

2 0

1 9

ENGINE CONTROLS (Items 1 through 8)

1.  RUN-

RUN-  STOP SWITCH

STOP SWITCH

When placed in the “RUN” position, this switch ener- gizes the fuel solenoid and other electric accessories. When placed in the “STOP” position, the flow of fuel to the injection pump is stopped to shut down the engine. (Note: If the switch is left in the “RUN” position and the engine is not running, the battery will be drained by the fuel solenoid).

2. START PUSHBUTTON

Energizes the starter motor to crank the engine. With the engine

3. FUEL LEVEL GAUGE AND LIGHT ![]() Displays the level of diesel fuel in the

Displays the level of diesel fuel in the

COMMANDER 400