INSTALLATIONA-3

SELECT SUITABLE LOCATION

Locate the welder in a dry location where there is free circulation of clean air into the louvers in the back and out the front of the unit. A location that minimizes the amount of smoke and dirt drawn into the rear louvers reduces the chance of dirt accumulation that can block air passages and cause overheating.

STACKING

TILTING

Each machine must be placed on a secure, level sur- face, either directly or on a recommended undercar- riage. The machine may topple over if this procedure is not followed.

OUTPUT CONNECTIONS

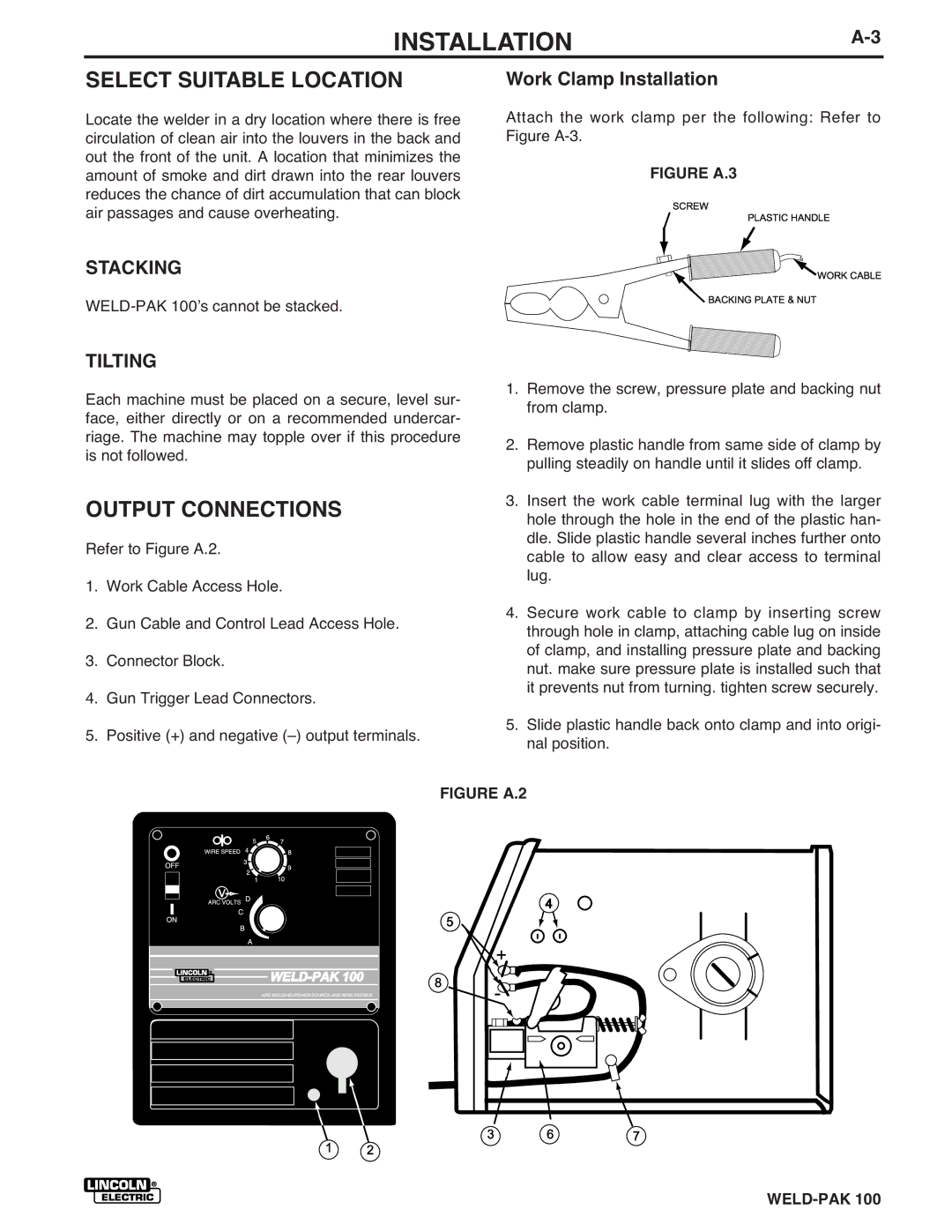

Refer to Figure A.2.

1.Work Cable Access Hole.

2.Gun Cable and Control Lead Access Hole.

3.Connector Block.

4.Gun Trigger Lead Connectors.

5.Positive (+) and negative

Work Clamp Installation

Attach the work clamp per the following: Refer to Figure

FIGURE A.3

SCREW

PLASTIC HANDLE

![]() WORK CABLE

WORK CABLE

![]() BACKING PLATE & NUT

BACKING PLATE & NUT

1.Remove the screw, pressure plate and backing nut from clamp.

2.Remove plastic handle from same side of clamp by pulling steadily on handle until it slides off clamp.

3.Insert the work cable terminal lug with the larger hole through the hole in the end of the plastic han- dle. Slide plastic handle several inches further onto cable to allow easy and clear access to terminal lug.

4.Secure work cable to clamp by inserting screw through hole in clamp, attaching cable lug on inside of clamp, and installing pressure plate and backing nut. make sure pressure plate is installed such that it prevents nut from turning. tighten screw securely.

5.Slide plastic handle back onto clamp and into origi- nal position.

FIGURE A.2

![]()

![]()

![]()

4

5

![]() +

+

8

-

3 | 6 | 7 |

1 2