INSTALLATIONA-5

![]() WARNING

WARNING

CYLINDER may explode if dam- aged. Keep cylinder upright and chained to support

• Keep cylinder away from areas where it may be damaged.

•Never lift welder with cylinder attached.

•Never allow welding electrode to touch cylinder.

•Keep cylinder away from welding or other live electrical circuits.

![]() WARNING

WARNING

BUILDUP OF SHIELDING GAS may harm health or kill.

• Shut off shielding gas supply when not in use.

•SEE AMERICAN NATIONAL STANDARD

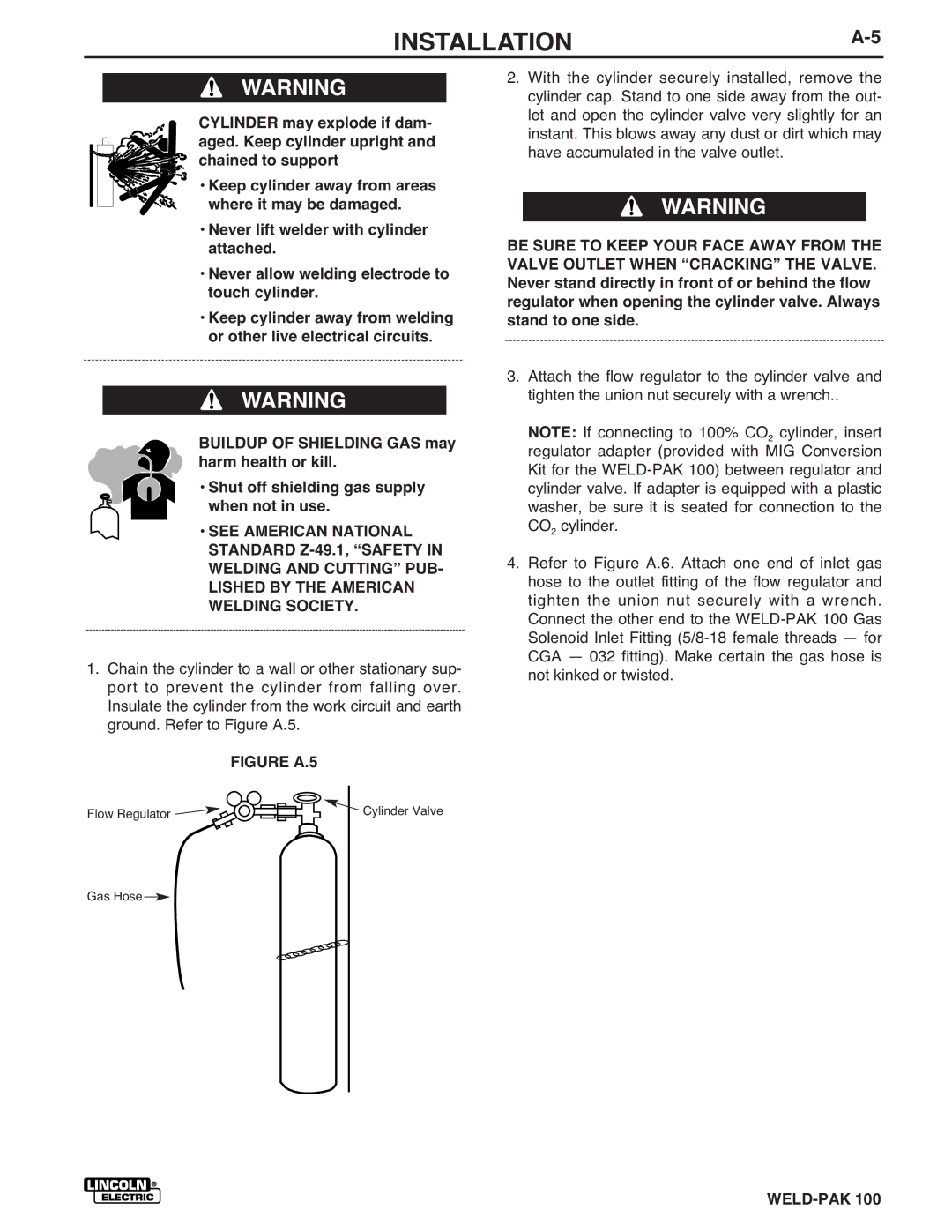

1.Chain the cylinder to a wall or other stationary sup- port to prevent the cylinder from falling over. Insulate the cylinder from the work circuit and earth ground. Refer to Figure A.5.

FIGURE A.5

Flow Regulator | Cylinder Valve |

Gas Hose ![]()

2.With the cylinder securely installed, remove the cylinder cap. Stand to one side away from the out- let and open the cylinder valve very slightly for an instant. This blows away any dust or dirt which may have accumulated in the valve outlet.

![]() WARNING

WARNING

BE SURE TO KEEP YOUR FACE AWAY FROM THE VALVE OUTLET WHEN “CRACKING” THE VALVE. Never stand directly in front of or behind the flow regulator when opening the cylinder valve. Always stand to one side.

3.Attach the flow regulator to the cylinder valve and tighten the union nut securely with a wrench..

NOTE: If connecting to 100% CO2 cylinder, insert regulator adapter (provided with MIG Conversion Kit for the

4.Refer to Figure A.6. Attach one end of inlet gas hose to the outlet fitting of the flow regulator and tighten the union nut securely with a wrench. Connect the other end to the