OPERATIONB-3

out when tripped (Manual reset).

![]()

![]()

![]() 2 1

2 1 ![]()

![]()

![]()

![]()

![]()

![]() 3

3

![]()

![]()

![]()

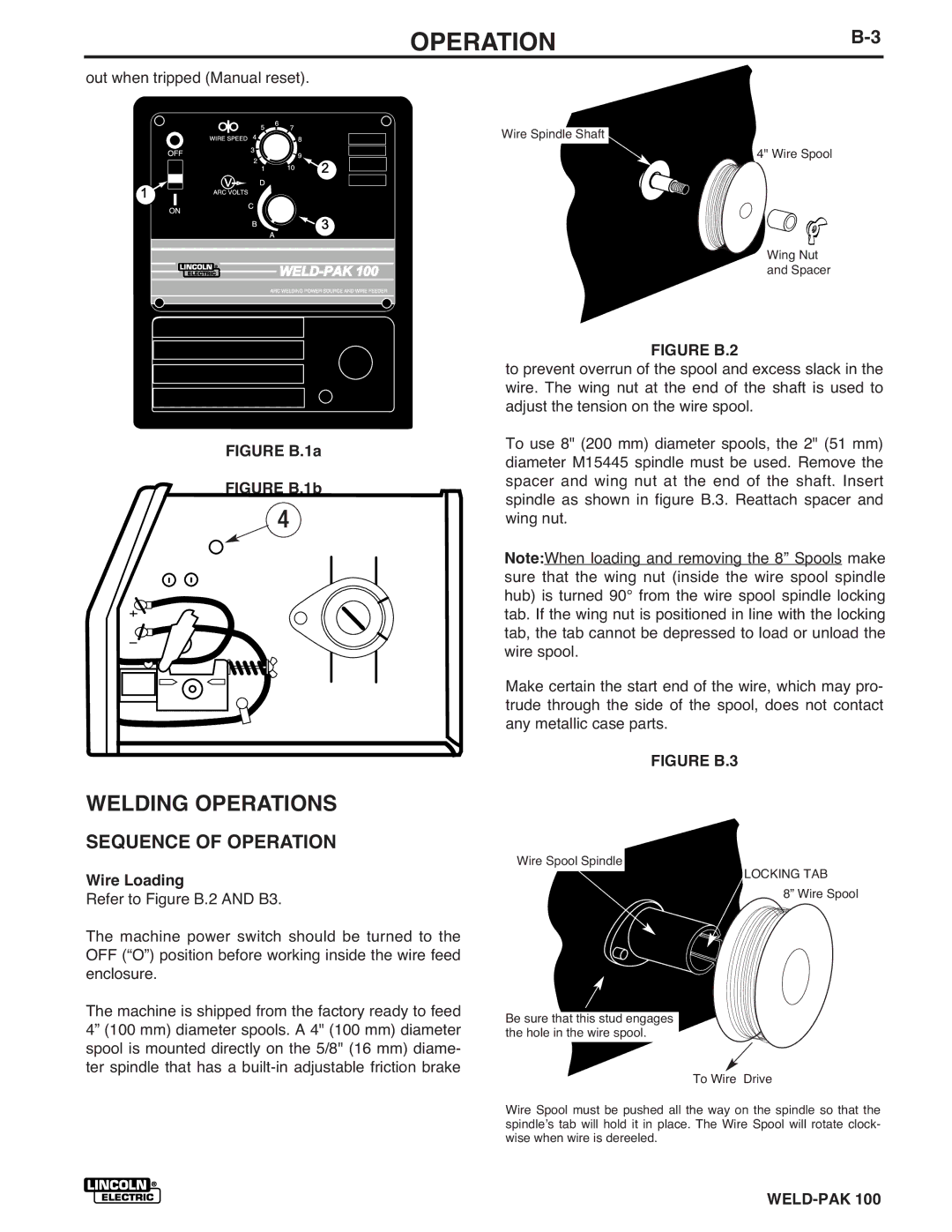

Wire Spindle Shaft

4" Wire Spool

Wing Nut

and Spacer

FIGURE B.1a

FIGURE B.1b

4

WELDING OPERATIONS

SEQUENCE OF OPERATION

Wire Loading

Refer to Figure B.2 AND B3.

The machine power switch should be turned to the OFF (“O”) position before working inside the wire feed enclosure.

The machine is shipped from the factory ready to feed 4” (100 mm) diameter spools. A 4" (100 mm) diameter spool is mounted directly on the 5/8" (16 mm) diame- ter spindle that has a

FIGURE B.2

to prevent overrun of the spool and excess slack in the wire. The wing nut at the end of the shaft is used to adjust the tension on the wire spool.

To use 8" (200 mm) diameter spools, the 2" (51 mm) diameter M15445 spindle must be used. Remove the spacer and wing nut at the end of the shaft. Insert spindle as shown in figure B.3. Reattach spacer and wing nut.

Note:When loading and removing the 8” Spools make sure that the wing nut (inside the wire spool spindle hub) is turned 90° from the wire spool spindle locking tab. If the wing nut is positioned in line with the locking tab, the tab cannot be depressed to load or unload the wire spool.

Make certain the start end of the wire, which may pro- trude through the side of the spool, does not contact any metallic case parts.

FIGURE B.3

Wire Spool Spindle

LOCKING TAB

8” Wire Spool

Be sure that this stud engages the hole in the wire spool.

To Wire Drive

Wire Spool must be pushed all the way on the spindle so that the spindleʼs tab will hold it in place. The Wire Spool will rotate clock- wise when wire is dereeled.