B-6 OPERATION

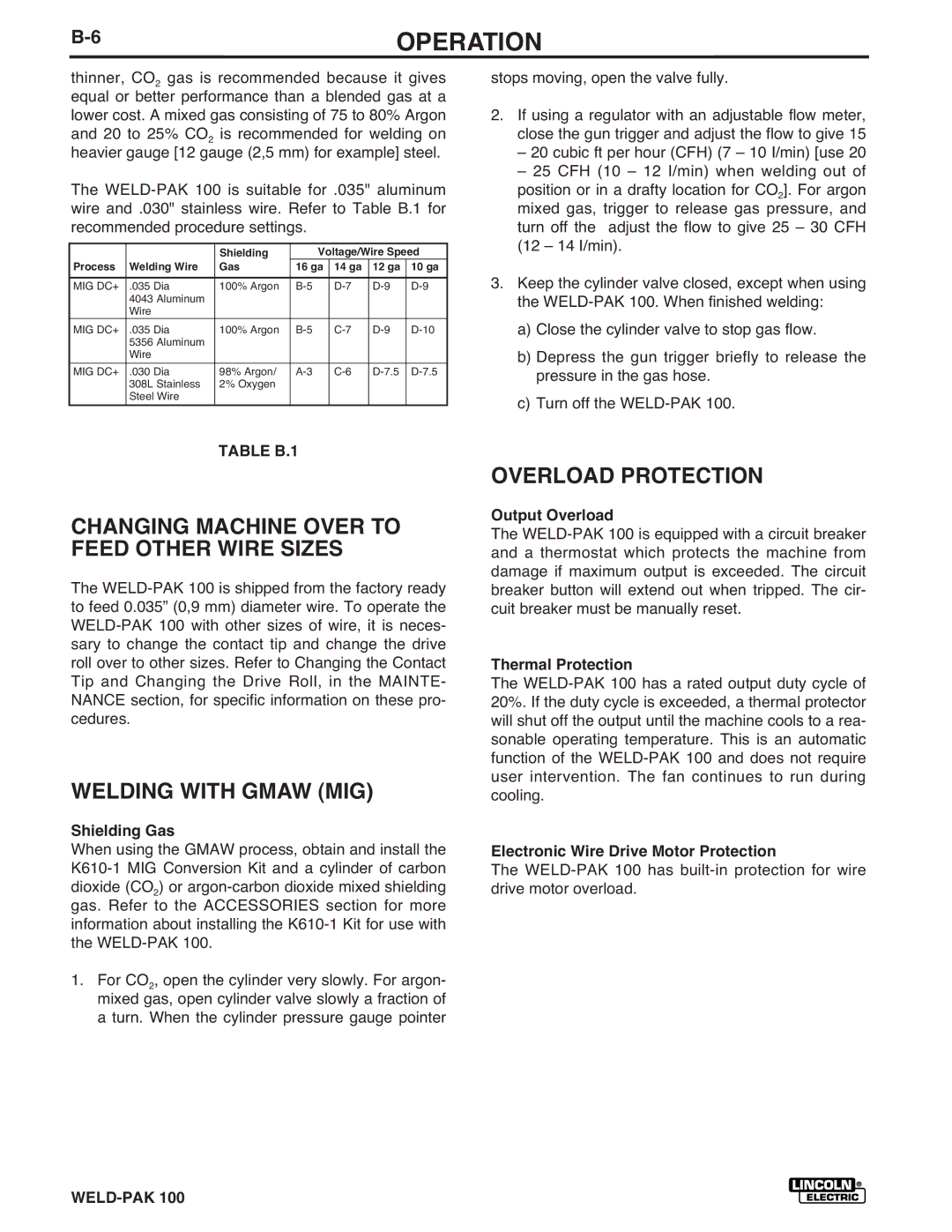

thinner, CO2 gas is recommended because it gives equal or better performance than a blended gas at a lower cost. A mixed gas consisting of 75 to 80% Argon and 20 to 25% CO2 is recommended for welding on heavier gauge [12 gauge (2,5 mm) for example] steel.

The

|

| Shielding | Voltage/Wire Speed | |||

Process | Welding Wire | Gas | 16 ga | 14 ga | 12 ga | 10 ga |

MIG DC+ | .035 Dia | 100% Argon | ||||

| 4043 Aluminum |

|

|

|

|

|

| Wire |

|

|

|

|

|

MIG DC+ | .035 Dia | 100% Argon | ||||

| 5356 Aluminum |

|

|

|

|

|

| Wire |

|

|

|

|

|

|

|

|

|

|

|

|

MIG DC+ | .030 Dia | 98% Argon/ | ||||

| 308L Stainless | 2% Oxygen |

|

|

|

|

| Steel Wire |

|

|

|

|

|

|

|

|

|

|

|

|

TABLE B.1

CHANGING MACHINE OVER TO FEED OTHER WIRE SIZES

The

WELDING WITH GMAW (MIG)

Shielding Gas

When using the GMAW process, obtain and install the

1.For CO2, open the cylinder very slowly. For argon- mixed gas, open cylinder valve slowly a fraction of a turn. When the cylinder pressure gauge pointer

stops moving, open the valve fully.

2.If using a regulator with an adjustable flow meter, close the gun trigger and adjust the flow to give 15

–20 cubic ft per hour (CFH) (7 – 10 I/min) [use 20

–25 CFH (10 – 12 I/min) when welding out of

position or in a drafty location for CO2]. For argon mixed gas, trigger to release gas pressure, and turn off the adjust the flow to give 25 – 30 CFH (12 – 14 I/min).

3.Keep the cylinder valve closed, except when using the

a) Close the cylinder valve to stop gas flow.

b) Depress the gun trigger briefly to release the pressure in the gas hose.

c) Turn off the

OVERLOAD PROTECTION

Output Overload

The

Thermal Protection

The

Electronic Wire Drive Motor Protection

The