| LEARNING TO WELD |

| |

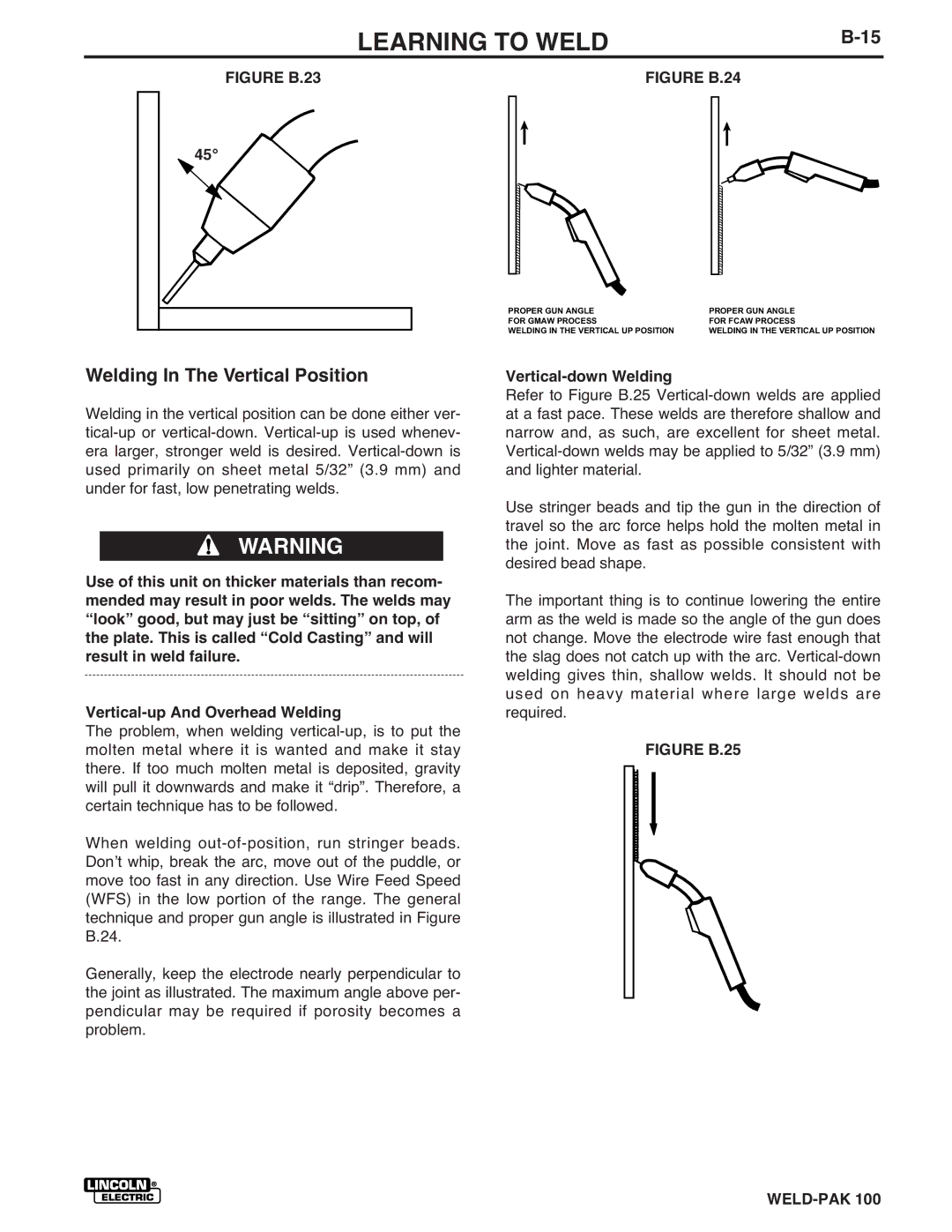

FIGURE B.23 | FIGURE B.24 | ||

45°

Welding In The Vertical Position

Welding in the vertical position can be done either ver-

![]() WARNING

WARNING

Use of this unit on thicker materials than recom- mended may result in poor welds. The welds may “look” good, but may just be “sitting” on top, of the plate. This is called “Cold Casting” and will result in weld failure.

The problem, when welding

When welding

Generally, keep the electrode nearly perpendicular to the joint as illustrated. The maximum angle above per- pendicular may be required if porosity becomes a problem.

PROPER GUN ANGLE | PROPER GUN ANGLE |

FOR GMAW PROCESS | FOR FCAW PROCESS |

WELDING IN THE VERTICAL UP POSITION | WELDING IN THE VERTICAL UP POSITION |

Vertical-down Welding

Refer to Figure B.25

Use stringer beads and tip the gun in the direction of travel so the arc force helps hold the molten metal in the joint. Move as fast as possible consistent with desired bead shape.

The important thing is to continue lowering the entire arm as the weld is made so the angle of the gun does not change. Move the electrode wire fast enough that the slag does not catch up with the arc.