LEARNING TO WELD |

|

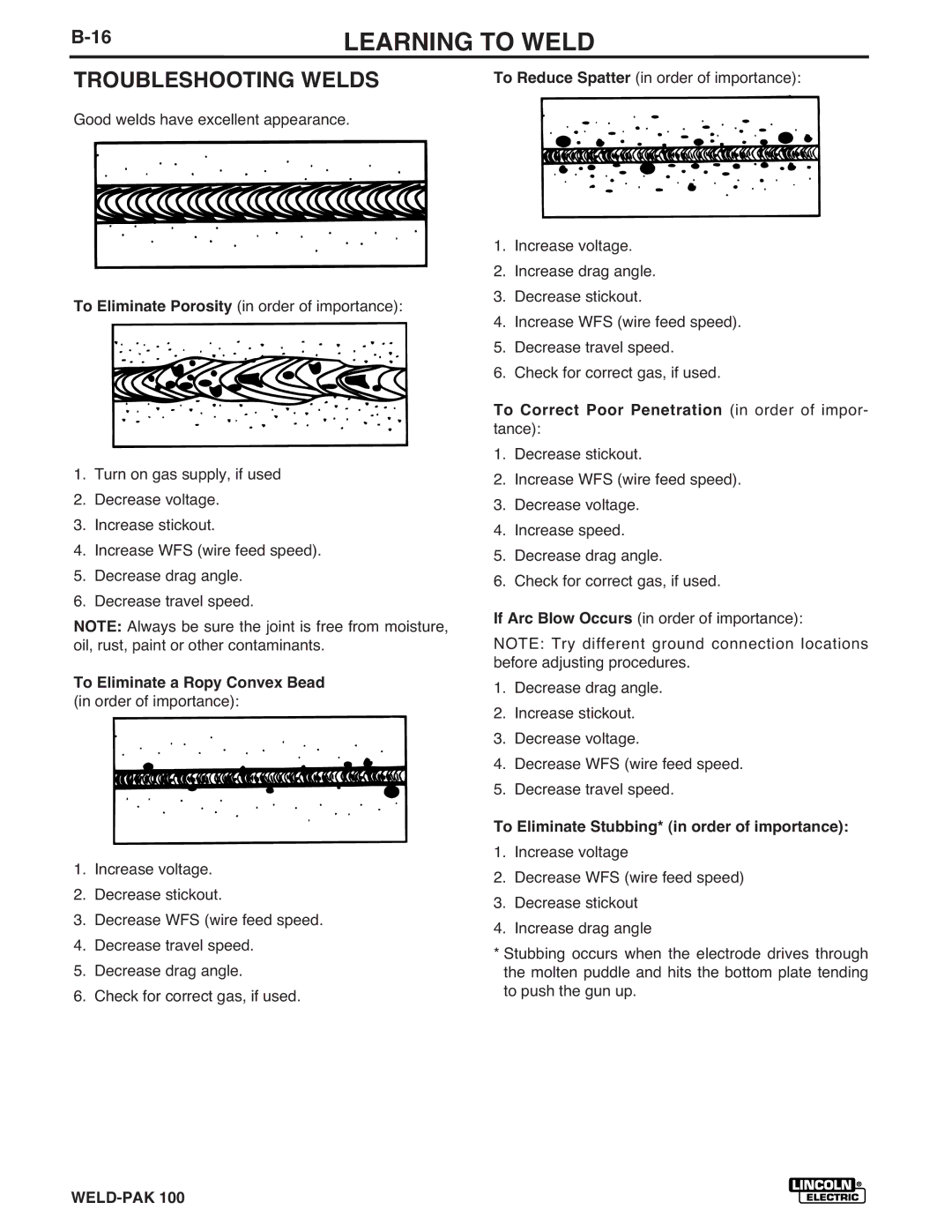

TROUBLESHOOTING WELDS

Good welds have excellent appearance.

To Eliminate Porosity (in order of importance):

1.Turn on gas supply, if used

2.Decrease voltage.

3.Increase stickout.

4.Increase WFS (wire feed speed).

5.Decrease drag angle.

6.Decrease travel speed.

NOTE: Always be sure the joint is free from moisture, oil, rust, paint or other contaminants.

To Eliminate a Ropy Convex Bead (in order of importance):

1.Increase voltage.

2.Decrease stickout.

3.Decrease WFS (wire feed speed.

4.Decrease travel speed.

5.Decrease drag angle.

6.Check for correct gas, if used.

To Reduce Spatter (in order of importance):

1.Increase voltage.

2.Increase drag angle.

3.Decrease stickout.

4.Increase WFS (wire feed speed).

5.Decrease travel speed.

6.Check for correct gas, if used.

To Correct Poor Penetration (in order of impor- tance):

1.Decrease stickout.

2.Increase WFS (wire feed speed).

3.Decrease voltage.

4.Increase speed.

5.Decrease drag angle.

6.Check for correct gas, if used.

If Arc Blow Occurs (in order of importance):

NOTE: Try different ground connection locations before adjusting procedures.

1.Decrease drag angle.

2.Increase stickout.

3.Decrease voltage.

4.Decrease WFS (wire feed speed.

5.Decrease travel speed.

To Eliminate Stubbing* (in order of importance):

1.Increase voltage

2.Decrease WFS (wire feed speed)

3.Decrease stickout

4.Increase drag angle

*Stubbing occurs when the electrode drives through the molten puddle and hits the bottom plate tending to push the gun up.