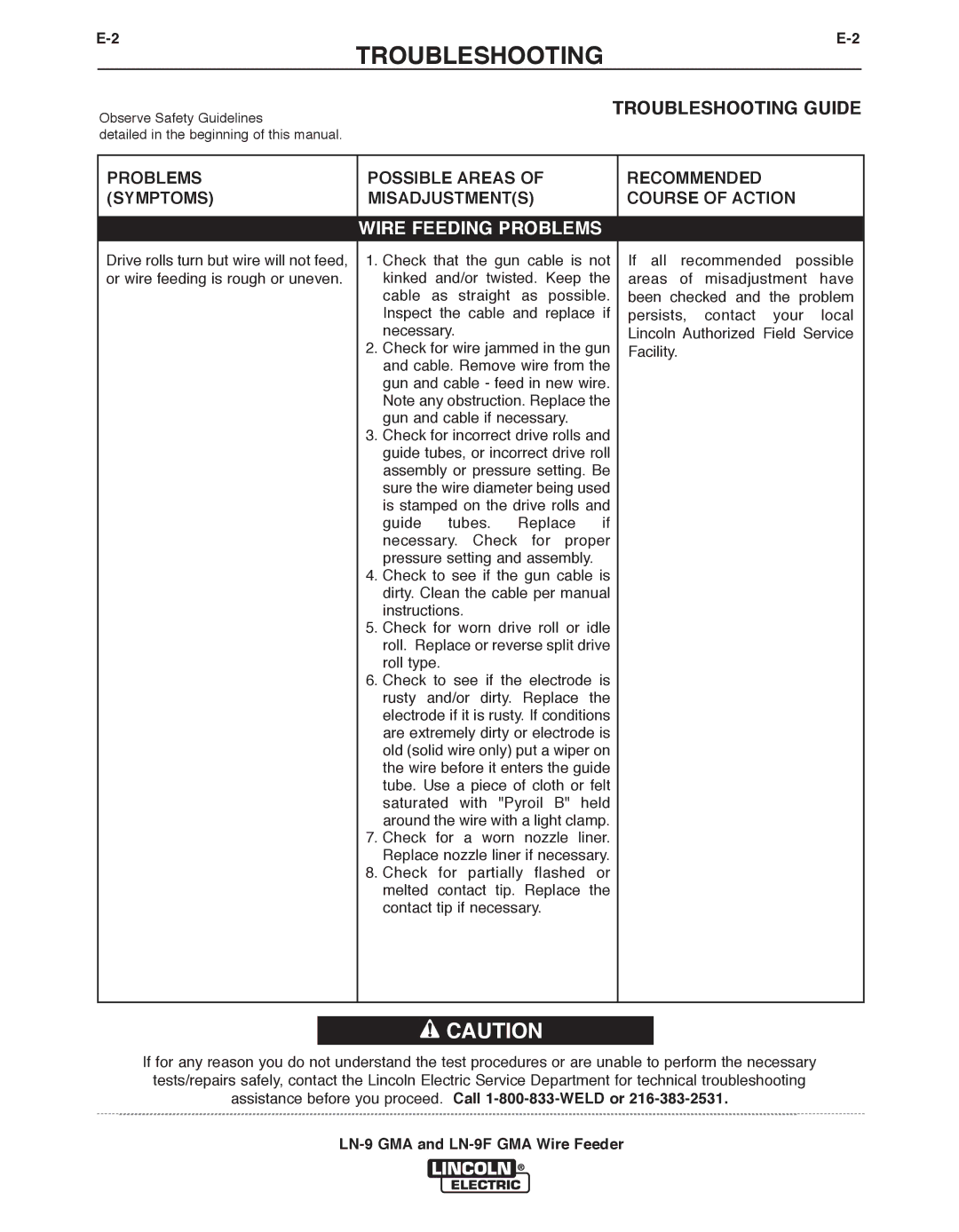

TROUbLESHOOTING

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUbLESHOOTING GUIDE

PRObLEMS (SYMPTOMS)

Drive rolls turn but wire will not feed, or wire feeding is rough or uneven.

POSSIbLE AREAS OF

MISADJUSTMENT(S)

WIRE FEEDING PRObLEMS

1.Check that the gun cable is not kinked and/or twisted. Keep the cable as straight as possible. Inspect the cable and replace if necessary.

2.Check for wire jammed in the gun and cable. Remove wire from the gun and cable - feed in new wire. Note any obstruction. Replace the gun and cable if necessary.

3.Check for incorrect drive rolls and guide tubes, or incorrect drive roll assembly or pressure setting. Be sure the wire diameter being used is stamped on the drive rolls and guide tubes. Replace if necessary. Check for proper pressure setting and assembly.

4.Check to see if the gun cable is dirty. Clean the cable per manual instructions.

5.Check for worn drive roll or idle roll. Replace or reverse split drive roll type.

6.Check to see if the electrode is rusty and/or dirty. Replace the electrode if it is rusty. If conditions are extremely dirty or electrode is old (solid wire only) put a wiper on the wire before it enters the guide tube. Use a piece of cloth or felt saturated with "Pyroil B" held around the wire with a light clamp.

7.Check for a worn nozzle liner. Replace nozzle liner if necessary.

8.Check for partially flashed or melted contact tip. Replace the contact tip if necessary.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas of misadjustment have been checked and the problem persists, contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the necessary tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call