INSTALLATION

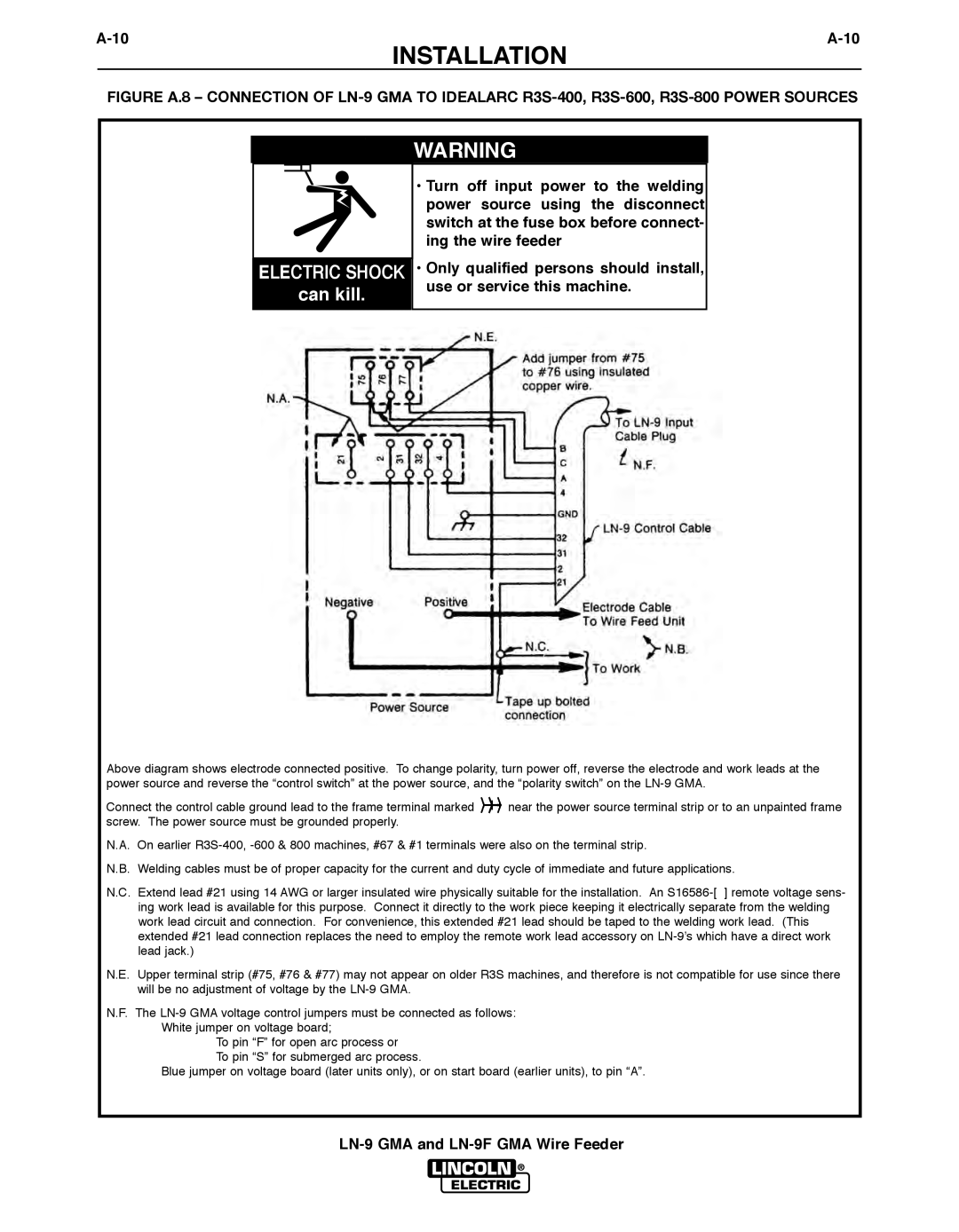

FIGURE A.8 – CONNECTION OF LN-9 GMA TO IDEALARC R3S-400, R3S-600, R3S-800 POWER SOURCES

ELECTRIC SHOCK

can kill.

WARNING

•Turn off input power to the welding power source using the disconnect switch at the fuse box before connect- ing the wire feeder

•Only qualified persons should install, use or service this machine.

Above diagram shows electrode connected positive. To change polarity, turn power off, reverse the electrode and work leads at the power source and reverse the “control switch” at the power source, and the “polarity switch” on the

Connect the control cable ground lead to the frame terminal marked | near the power source terminal strip or to an unpainted frame |

screw. The power source must be grounded properly. |

|

N.A. On earlier

N.B. Welding cables must be of proper capacity for the current and duty cycle of immediate and future applications.

N.C. Extend lead #21 using 14 AWG or larger insulated wire physically suitable for the installation. An

N.E. Upper terminal strip (#75, #76 & #77) may not appear on older R3S machines, and therefore is not compatible for use since there will be no adjustment of voltage by the

N.F. The

White jumper on voltage board;

To pin “F” for open arc process or

To pin “S” for submerged arc process.

Blue jumper on voltage board (later units only), or on start board (earlier units), to pin “A”.