MACHINE GROUNDING

LN-9 GMA wire feeders are grounded to the power source through the input cable. The power source grounding cable must be properly connected to electri- cal ground. See your power source operating manual for details.

WORK CAbLE CONNECTION

Connect a work lead of sufficient size and length between the proper output terminal on the power source and the work. See Table A-1. Be sure the con- nection to the work makes tight metal-to-metal electri- cal contact. Poor work lead connections can activate the grounding lead protector and/or result in poor weld- ing performance.

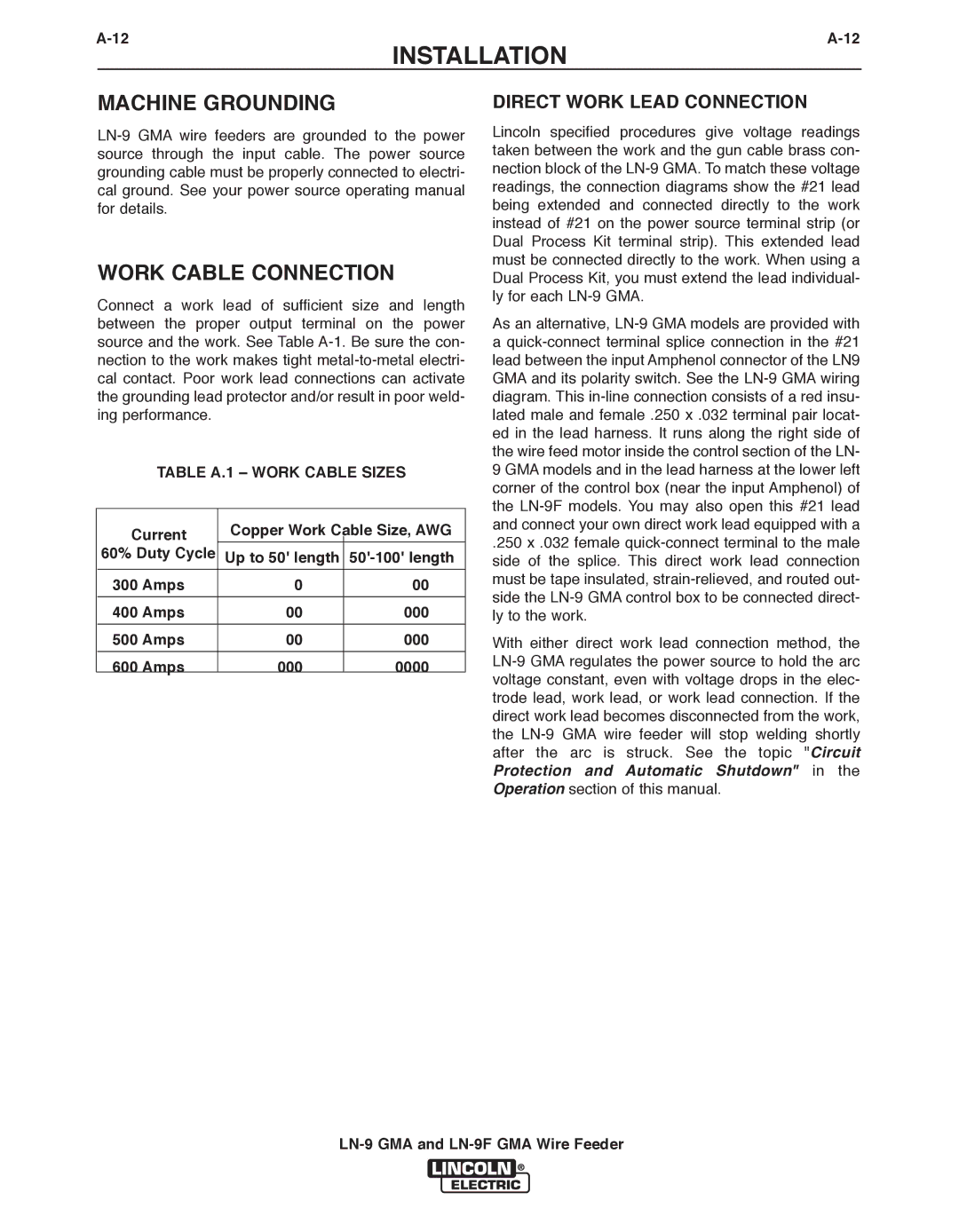

TAbLE A.1 – WORK CAbLE SIzES

Current | Copper Work Cable Size, AWG |

| |

60% Duty Cycle | Up to 50' length | 50'-100' Iength |

| | |

300 Amps | 0 | 00 |

| | |

400 Amps | 00 | 000 |

| | |

500 Amps | 00 | 000 |

| | |

600 Amps | 000 | 0000 |

DIRECT WORK LEAD CONNECTION

Lincoln specified procedures give voltage readings taken between the work and the gun cable brass con- nection block of the LN-9 GMA. To match these voltage readings, the connection diagrams show the #21 lead being extended and connected directly to the work instead of #21 on the power source terminal strip (or Dual Process Kit terminal strip). This extended lead must be connected directly to the work. When using a Dual Process Kit, you must extend the lead individual- ly for each LN-9 GMA.

As an alternative, LN-9 GMA models are provided with a quick-connect terminal splice connection in the #21 lead between the input Amphenol connector of the LN9 GMA and its polarity switch. See the LN-9 GMA wiring diagram. This in-line connection consists of a red insu- lated male and female .250 x .032 terminal pair locat- ed in the lead harness. It runs along the right side of the wire feed motor inside the control section of the LN- 9 GMA models and in the lead harness at the lower left corner of the control box (near the input Amphenol) of the LN-9F models. You may also open this #21 lead and connect your own direct work lead equipped with a

.250 x .032 female quick-connect terminal to the male side of the splice. This direct work lead connection must be tape insulated, strain-relieved, and routed out- side the LN-9 GMA control box to be connected direct- ly to the work.

With either direct work lead connection method, the LN-9 GMA regulates the power source to hold the arc voltage constant, even with voltage drops in the elec- trode lead, work lead, or work lead connection. If the direct work lead becomes disconnected from the work, the LN-9 GMA wire feeder will stop welding shortly after the arc is struck. See the topic "Circuit Protection and Automatic Shutdown" in the Operation section of this manual.