Eagle 10,000

Eagle 10,000

ISAFETYi

Electric Shock can kill ARC Rays can burn

Safety

Fumes and Gases

Can be dangerous

Welding Cutting

Powered equipment

Cylinder may explode

Sparks can cause fire or If damaged Explosion

Sûreté Pour Soudage a L’Arc

Précautions DE Sûreté

Master Table of Contents for ALL Sections

Table of Contents Installation Section

Height Width Depth Weight

Installation

Technical Specifications Eagle 10,000 K2343-1,K2343-2

Machine Grounding

Safety Precautions

Spark Arrester

Towing

Fuel Gasoline Fuel only

Vehicle Mounting

Follow vehicle manufacturer’s instructions

Do not overfill tank, fuel expansion may cause overflow

Angle of Operation

Additional Safety Precautions High Altitude Operation

Lifting

Location / Ventilation

Additional Safety Precautions

Connection of Lincoln Electric Wire Feeders

Instructions

Welder Operation

120/240 Volt Dual Voltage Receptacle

Auxiliary Power

Duplex Receptacles

Motor Starting

These Devices Without

Electrical Device USE with the Eagle 10,000

Additional Resistive

Type Loads

Simultaneous Welding and Power

Auxiliary Power While Welding

Standby Power Connections

Connection diagram shown Eagle 10,000

Figure A.1

Connection of Eagle 10,000 to Premises Wiring

Table of Contents Operation Section

Operation

Engine Switch

General Description

Welder Controls Function and Operation

OPERATIONB-3

Range Switch

Eagle 10,000 Approximate Fuel Consumption

Control Dial

BREAK-IN Period

STARTING/SHUTDOWN Instructions

Starting the Engine

Stopping the Engine

Welding Process

Wire Feed Welding Processes

TIG Constant Current Welding

ARC Gouging

Summary of Welding Processes

Typical Current Ranges 1 for Tungsten ELECTRODES2

Table of Contents Accessories Section

K1745-1 GAS Cylinder Holder

Accessories

Optional Equipment Field Installed

Recommended Equipment

Wire Feed

Plasma Cutting Stick

TIG Welding

Eagle 10,000

Table of Contents Maintenance Section

Safety Precautions

Maintenance

Engine OIL Change

Engine OIL Refill Capacities

OIL Filter Change

AIR Cleaner and Other Maintenance

Engine Adjustments

Figure D.1 Major Component Locations

Eagle 10,000

1TABLE of CONTENTS-THEORY of Operation Section E-1

Theory of Operation

BATTERY, STARTER, ENGINE, ROTOR, STATOR, and Idler Solenoid

Figure E.3 Rotor Field Feedback and Auxiliary Power

Rotor Field Feedback Auxiliary Power

Output BRIDGE, CHOKE, and Output Terminals

Weld WINDING, REACTOR, and Range Switch

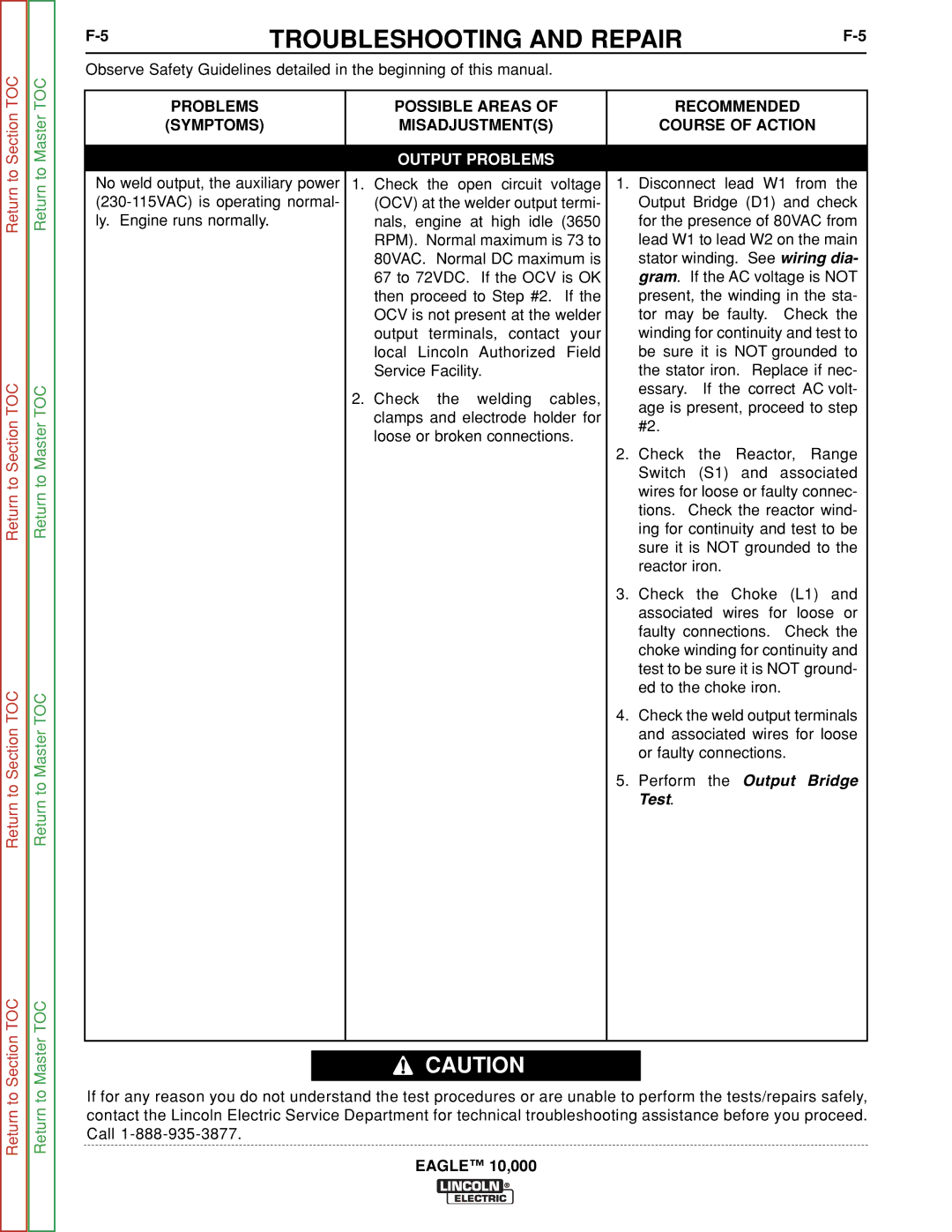

1TABLE of Contents Troubleshooting and Repair F-1

HOW to USE Troubleshooting Guide

2TROUBLESHOOTING and REPAIRF-2

PC Board Troubleshooting Procedures

Troubleshooting and Repair

Perform the Rotor Voltage Test

Recommended Course of Action

Problems Possible Areas Symptoms Misadjustments

Possible Areas Misadjustments

Problems Symptoms

Rotor Voltage2. PTestrform

Engine Problems

Wiring

Charging Circuit Test

BridgePerformTestthe. Output Rectifier

Eagle 10,000

Materials Needed

Rotor Voltage Test

Test Description

Rotor Voltage Test

Test Procedure

Remove the case top, then reinstall the fuel cap

Rotor Resistance Test

Remove the case top, then replace the fuel cap

Rotor Resistance Test

Troubleshooting and Repair

Eagle 10,000

Auxiliary and Field Winding Test

To test the 230 VAC winding

Auxiliary and Field Winding Test

To test the 115 VAC winding

To test the field winding

Eagle 10,000

Output Rectifier Bridge Test

Figure F.4 Location of Output Rectifier Leads

Output Rectifier Bridge Test

Charging Circuit Test

Figure F.5 Location of Voltage Regulator

Charging Circuit Test

Engine Throttle Adjustment Test

Strobe-tach Method

Engine Throttle Adjustment Test

Frequency Counter Method

Figure F.7

Oscilloscope Method Vibratach Method

Engine Throttle Adjustment Test

High Idle no Load Output Control AT Maximum

Scope Settings

Normal Open Circuit Voltage Waveform 115VAC Supply

Machine Loaded to 200 Amps AT 26 VDC

Typical DC Weld Output Waveform CC Mode

Machine Loaded

Abnormal Open Circuit DC Weld Voltage Waveform

Normal Open Circuit DC Weld Voltage Waveform CC Mode

Brush Removal and Replacement

Procedure

Brush Removal and Replacement

Figure F.9 Brush LEADS/BRUSHES Retained with Cable TIE

Slip Rings

Eagle 10,000

Printed Circuit Board Removal Replacement

Printed Circuit Board Removal

Replacement

Troubleshooting and Repair

Eagle 10,000

Output Rectifier Bridge Removal Replacement

43TROUBLESHOOTING and REPAIRF-43

Output Rectifier Bridge Removal

44TROUBLESHOOTING and REPAIRF-44

45TROUBLESHOOTING and REPAIRF-45

Eagle 10,000

Instructions

ENGINE/ROTOR Removal and Replacement

Figure F.12 Component LOCATIONS, ENGINE/ROTOR Removal

ENGINE/ROTOR Removal and Replacement

Engine and Rotor Removal Procedure

Figure F.13 Engine and Rotor Removed from Stator THRU-BOLT

Rotor Removal Procedure

ENGINE/ROTOR Removal

Replacement KIT S20788

Reassembly Procedure

Retest After Repair

Auxiliary Power Receptacle OUTPUT1

Engine Output

Welder DC OUTPUT1

Table of Contents Diagram Section

Eagle 10,000 Kohler

Electrical Diagrams

Wiring Diagram Code 11397 M21271

Terminal

Schematic Complete Machine Code 11096 L12259

Torroid Core located on

Schematic Complete Machine Code 11397 L13104

Schematic IDLER/FIELD Control P.C. Board L12197