Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-10. Arm complete, Arm holder (cont.)

DISASSEMBLING

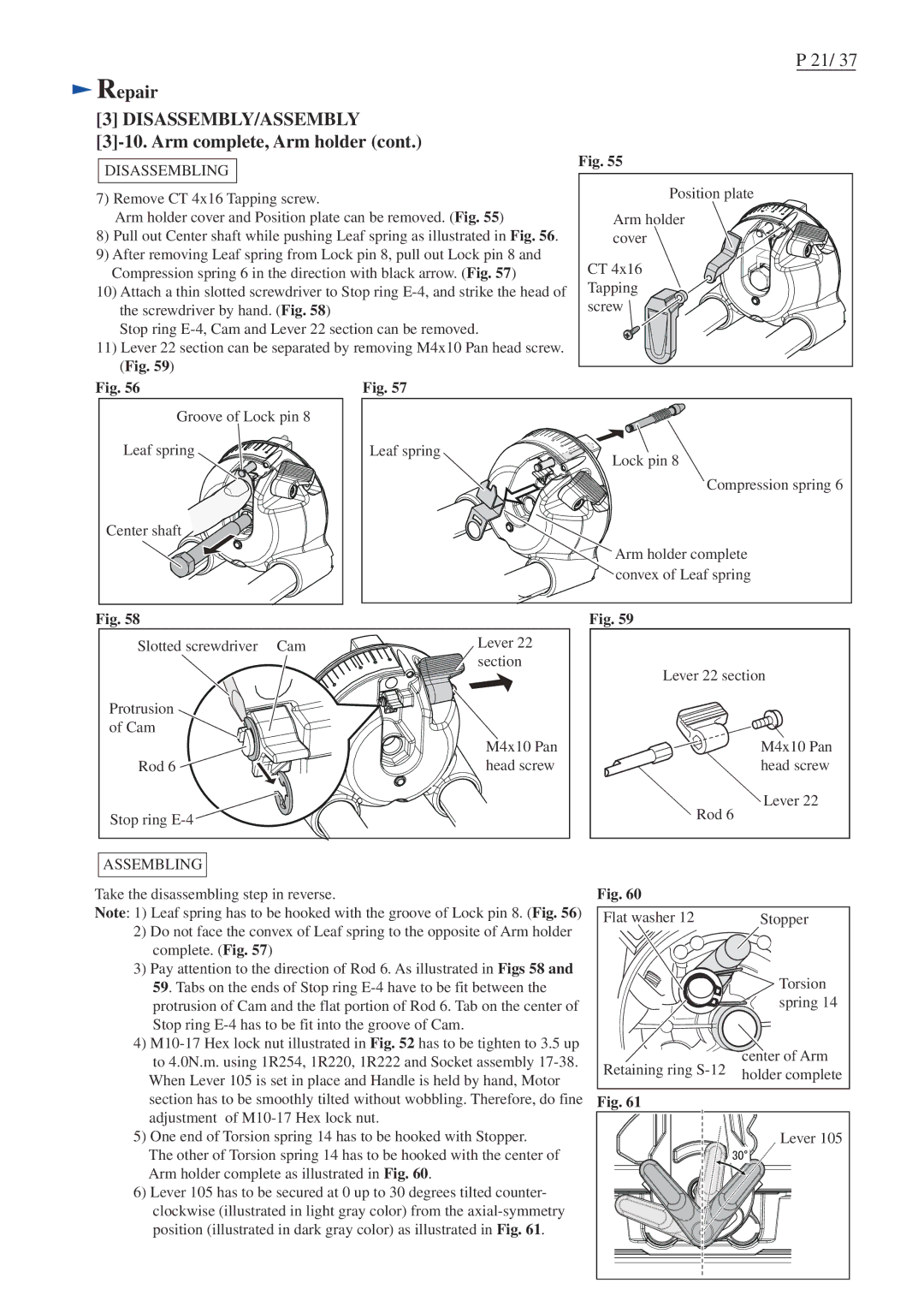

7) Remove CT 4x16 Tapping screw.

Arm holder cover and Position plate can be removed. (Fig. 55)

8)Pull out Center shaft while pushing Leaf spring as illustrated in Fig. 56.

9)After removing Leaf spring from Lock pin 8, pull out Lock pin 8 and Compression spring 6 in the direction with black arrow. (Fig. 57)

10)Attach a thin slotted screwdriver to Stop ring

Stop ring

11)Lever 22 section can be separated by removing M4x10 Pan head screw. (Fig. 59)

Fig. 56 | Fig. 57 |

P 21/ 37

Fig. 55

Position plate

Arm holder cover

CT 4x16 Tapping screw ![]()

Groove of Lock pin 8 |

Leaf spring |

Center shaft |

Leaf spring | Lock pin 8 |

| |

| Compression spring 6 |

| Arm holder complete |

| convex of Leaf spring |

Fig. 58

Slotted screwdriver | Cam | Lever 22 |

|

| section |

Protrusion |

|

|

of Cam |

|

|

|

| M4x10 Pan |

Rod 6 |

| head screw |

Fig. 59

Lever 22 section

M4x10 Pan head screw

Stop ring |

ASSEMBLING |

Take the disassembling step in reverse.

Rod 6

Fig. 60

Lever 22

Note: 1) Leaf spring has to be hooked with the groove of Lock pin 8. (Fig. 56)

2)Do not face the convex of Leaf spring to the opposite of Arm holder complete. (Fig. 57)

3)Pay attention to the direction of Rod 6. As illustrated in Figs 58 and 59. Tabs on the ends of Stop ring

4)

When Lever 105 is set in place and Handle is held by hand, Motor section has to be smoothly tilted without wobbling. Therefore, do fine adjustment of

5) One end of Torsion spring 14 has to be hooked with Stopper.

The other of Torsion spring 14 has to be hooked with the center of Arm holder complete as illustrated in Fig. 60.

6)Lever 105 has to be secured at 0 up to 30 degrees tilted counter- clockwise (illustrated in light gray color) from the

Flat washer 12 | Stopper |

Torsion spring 14

Retaining ring | center of Arm | |

holder complete | ||

|

Fig. 61

Lever 105 |