Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-12. Laser Mechanism (for LS1016L only: cont.)

ASSEMBLING

Take the disassembling step in reverse.

Note: 1) Hook one end of Torsion springs 9(A) to the groove of Laser circuit complete, and hook the other end to the groove of Block B. Meanwhile, hook one end of Torsion springs 9(B) to the groove of Block C, and hook the other end to the groove of Block B as illustrated in Fig. 66. Be careful each end of the Torsion springs. After tightening M3x6 Pan head screws (A) and (B), check if both Blocks B and C can be smoothly pivoted due to the reaction force of Torsion springs 9(A) and 9(B).

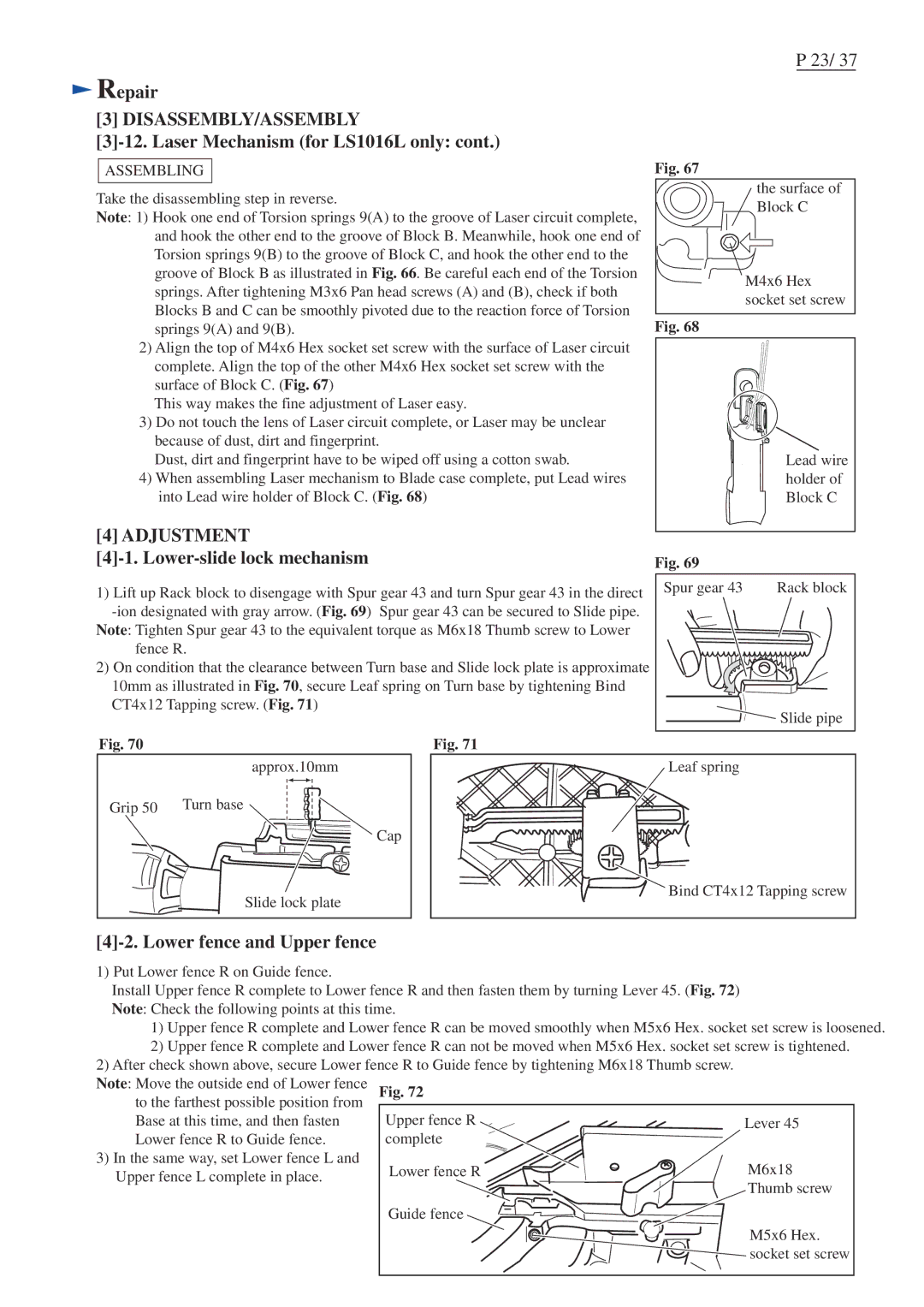

2)Align the top of M4x6 Hex socket set screw with the surface of Laser circuit complete. Align the top of the other M4x6 Hex socket set screw with the surface of Block C. (Fig. 67)

This way makes the fine adjustment of Laser easy.

3)Do not touch the lens of Laser circuit complete, or Laser may be unclear because of dust, dirt and fingerprint.

Dust, dirt and fingerprint have to be wiped off using a cotton swab.

4)When assembling Laser mechanism to Blade case complete, put Lead wires into Lead wire holder of Block C. (Fig. 68)

[4]ADJUSTMENT

[4]-1. Lower-slide lock mechanism

P 23/ 37

Fig. 67

the surface of Block C

M4x6 Hex socket set screw

Fig. 68

Lead wire holder of Block C

Fig. 69

1)Lift up Rack block to disengage with Spur gear 43 and turn Spur gear 43 in the direct

Note: Tighten Spur gear 43 to the equivalent torque as M6x18 Thumb screw to Lower fence R.

2)On condition that the clearance between Turn base and Slide lock plate is approximate 10mm as illustrated in Fig. 70, secure Leaf spring on Turn base by tightening Bind CT4x12 Tapping screw. (Fig. 71)

Fig. 70 | Fig. 71 |

Spur gear 43 | Rack block |

| Slide pipe |

|

|

|

|

|

|

|

|

|

|

|

|

|

Grip 50 | Turn base |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|