P 26/ 37

Repair

Repair

[4] ADJUSTMENT

[4]-5. Laser (for LS1016L only: Cont.)

Note: 1) In the process 10) and 11), backlash of M4x6 Hex socket set screw A or B may be happened. Therefore, turn each M4x6 Hex socket set screw clockwise carefully to prevent backlash.

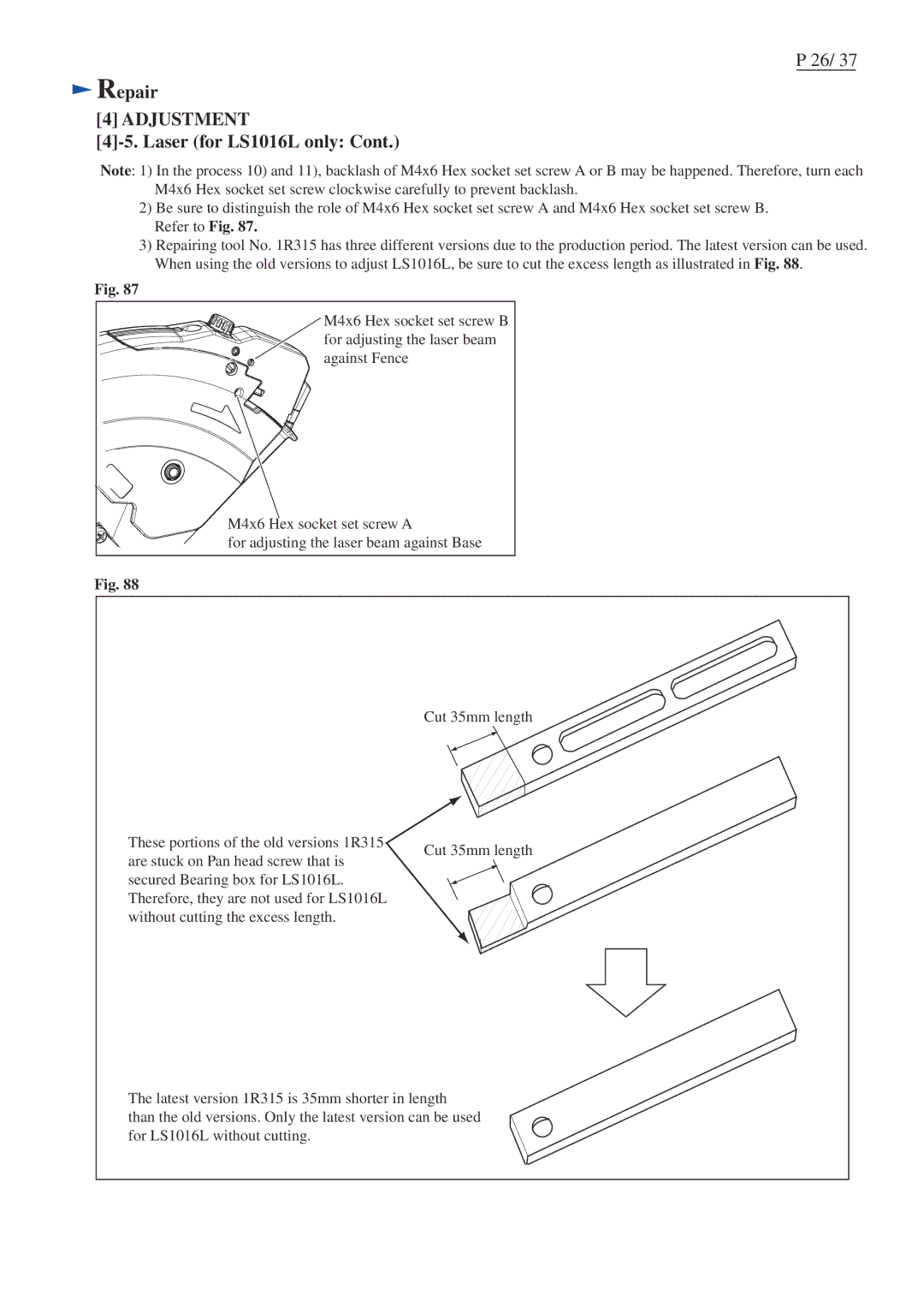

2)Be sure to distinguish the role of M4x6 Hex socket set screw A and M4x6 Hex socket set screw B. Refer to Fig. 87.

3)Repairing tool No. 1R315 has three different versions due to the production period. The latest version can be used. When using the old versions to adjust LS1016L, be sure to cut the excess length as illustrated in Fig. 88.

Fig. 87

M4x6 Hex socket set screw B for adjusting the laser beam against Fence

M4x6 Hex socket set screw A

for adjusting the laser beam against Base

Fig. 88

Cut 35mm length

These portions of the old versions 1R315 | Cut 35mm length | |

are stuck on Pan head screw that is | ||

| ||

secured Bearing box for LS1016L. |

| |

Therefore, they are not used for LS1016L |

| |

without cutting the excess length. |

|

The latest version 1R315 is 35mm shorter in length than the old versions. Only the latest version can be used for LS1016L without cutting.