P 7/ 37

Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Blade case, Motor section (cont.)

DISASSEMBLING

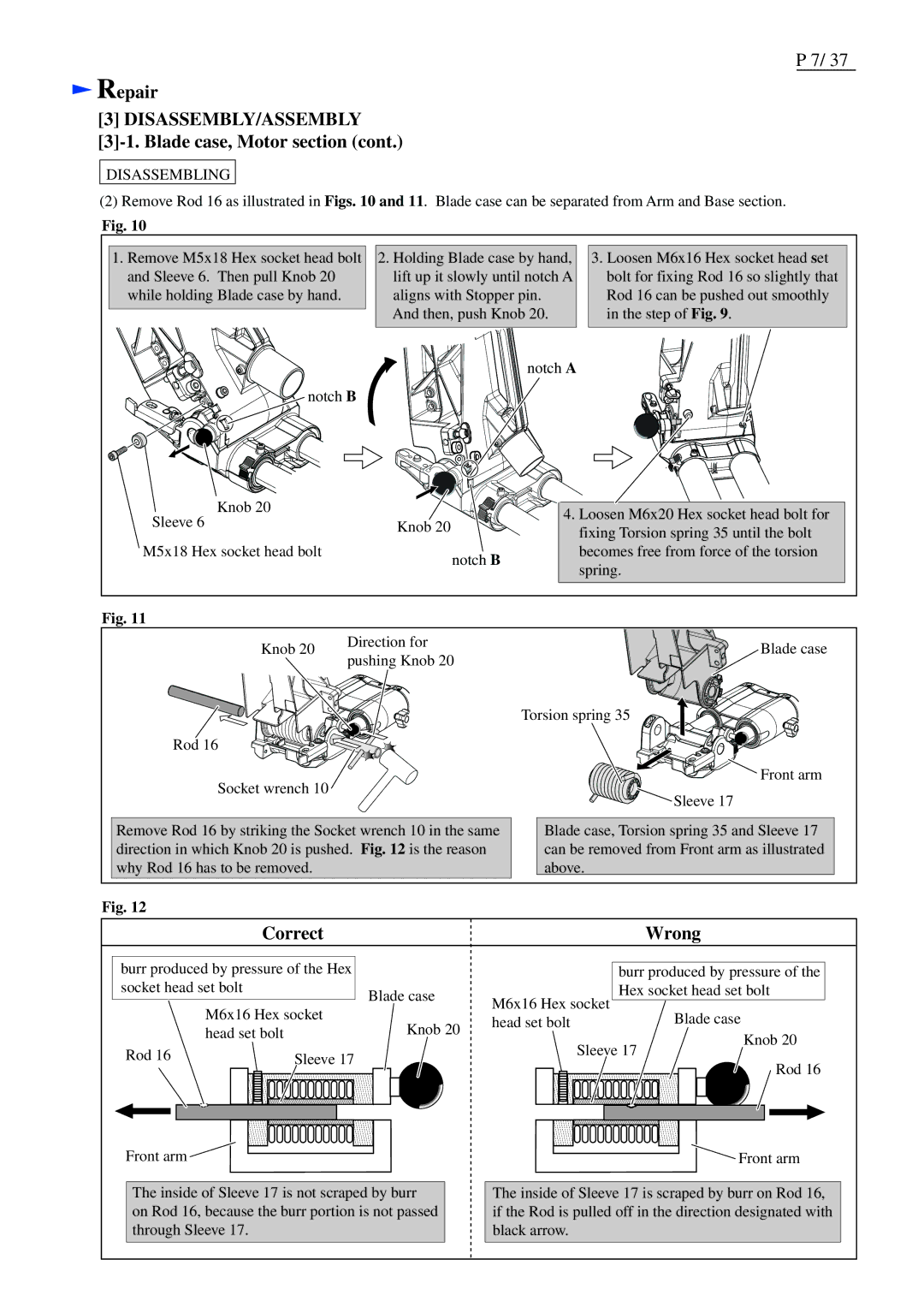

(2)Remove Rod 16 as illustrated in Figs. 10 and 11. Blade case can be separated from Arm and Base section.

Fig. 10

1.Remove M5x18 Hex socket head bolt and Sleeve 6. Then pull Knob 20 while holding Blade case by hand.

2.Holding Blade case by hand, lift up it slowly until notch A aligns with Stopper pin.

And then, push Knob 20.

3.Loosen M6x16 Hex socket head set bolt for fixing Rod 16 so slightly that Rod 16 can be pushed out smoothly in the step of Fig. 9.

notch A

notch B

Sleeve 6 | Knob 20 | |

Knob 20 | ||

|

M5x18 Hex socket head bolt | notch B |

|

4.Loosen M6x20 Hex socket head bolt for fixing Torsion spring 35 until the bolt becomes free from force of the torsion spring.

Fig. 11

Knob 20 | Direction for | Blade case | |

pushing Knob 20 | |||

|

| ||

|

| Torsion spring 35 | |

Rod 16 |

|

| |

Socket wrench 10 |

| Front arm | |

| Sleeve 17 | ||

|

|

Remove Rod 16 by striking the Socket wrench 10 in the same direction in which Knob 20 is pushed. Fig. 12 is the reason why Rod 16 has to be removed.

Blade case, Torsion spring 35 and Sleeve 17 can be removed from Front arm as illustrated above.

Fig. 12

Correct | Wrong |

burr produced by pressure of the Hex socket head set bolt

M6x16 Hex socket head set bolt

Rod 16 |

| Sleeve 17 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Blade case

Knob 20

| burr produced by pressure of the | |

M6x16 Hex socket | Hex socket head set bolt | |

Blade case | ||

head set bolt |

Sleeve 17 | Knob 20 |

| |

| Rod 16 |

Front arm ![]()

The inside of Sleeve 17 is not scraped by burr on Rod 16, because the burr portion is not passed through Sleeve 17.

![]() Front arm

Front arm

The inside of Sleeve 17 is scraped by burr on Rod 16, if the Rod is pulled off in the direction designated with black arrow.