P 3/ 37

Repair

Repair

CAUTION: Unplug the tool and remove the saw blade from the machine for safety before repair/ maintenance in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

| Code No. | Description | Use for |

|

|

|

|

|

|

| 1R028 | Bearing setting pipe | Mounting Retaining ring |

|

|

|

|

|

|

| 1R031 | Bearing setting pipe | Mounting Helical gear 27 |

|

|

|

|

|

|

| 1R034 | Bearing setting plate 12.2 | Mounting Helical gear 27 |

|

|

|

|

|

|

| 1R036 | Bearing setting plate 17.2 | Mounting Helical gear 28 |

|

|

|

|

|

|

| 1R045 | Gear extractor (large) | Mounting / Removing Helical gear 14 |

|

|

|

|

|

|

| 1R207 | Adjusting the bevel angle of Saw blade to 45 degree |

| |

|

|

|

|

|

| 1R208 | Adjusting the bevel angle of Saw blade to 90 degree |

| |

|

|

|

|

|

| 1R217 | Ring 22 | Removing Helical gear 27 |

|

| 1R220 | Ratchet head 27 | Attachment for 1R254 |

|

|

|

|

|

|

| 1R222 | Socket adapter | Attachment for 1R254 |

|

|

|

|

|

|

| 1R232 | Pipe 30 | Mounting Helical gear 28 |

|

|

|

|

|

|

| 1R254 | Torque wrench shaft 2 - 6 N.m | Tightening Hex lock nut |

|

|

|

|

|

|

| 1R269 | Bearing extractor (small) | Removing Ball bearings |

|

|

|

|

|

|

| 1R291 | Retaining ring S and R pliers | Removing Retaining ring in Gear section |

|

|

|

|

|

|

| 1R315 | Laser beam positioning jig | Adjusting Laser beam |

|

|

|

|

|

|

| 1R346 | Center attachment | Attachment for 1R045 |

|

|

|

|

|

|

| 1R361 | Bearing retainer wrench | Mounting / Removing Bearing retainer wrench |

|

|

|

|

| |

Flat washer 16 | Adjusting Laser beam |

| ||

|

|

|

| |

Socket | Attachment for 1R254 |

| ||

Box wrench 13 (standard accessory) | Installing /Removing Blade Adjusting Blade position |

| ||

|

|

|

|

|

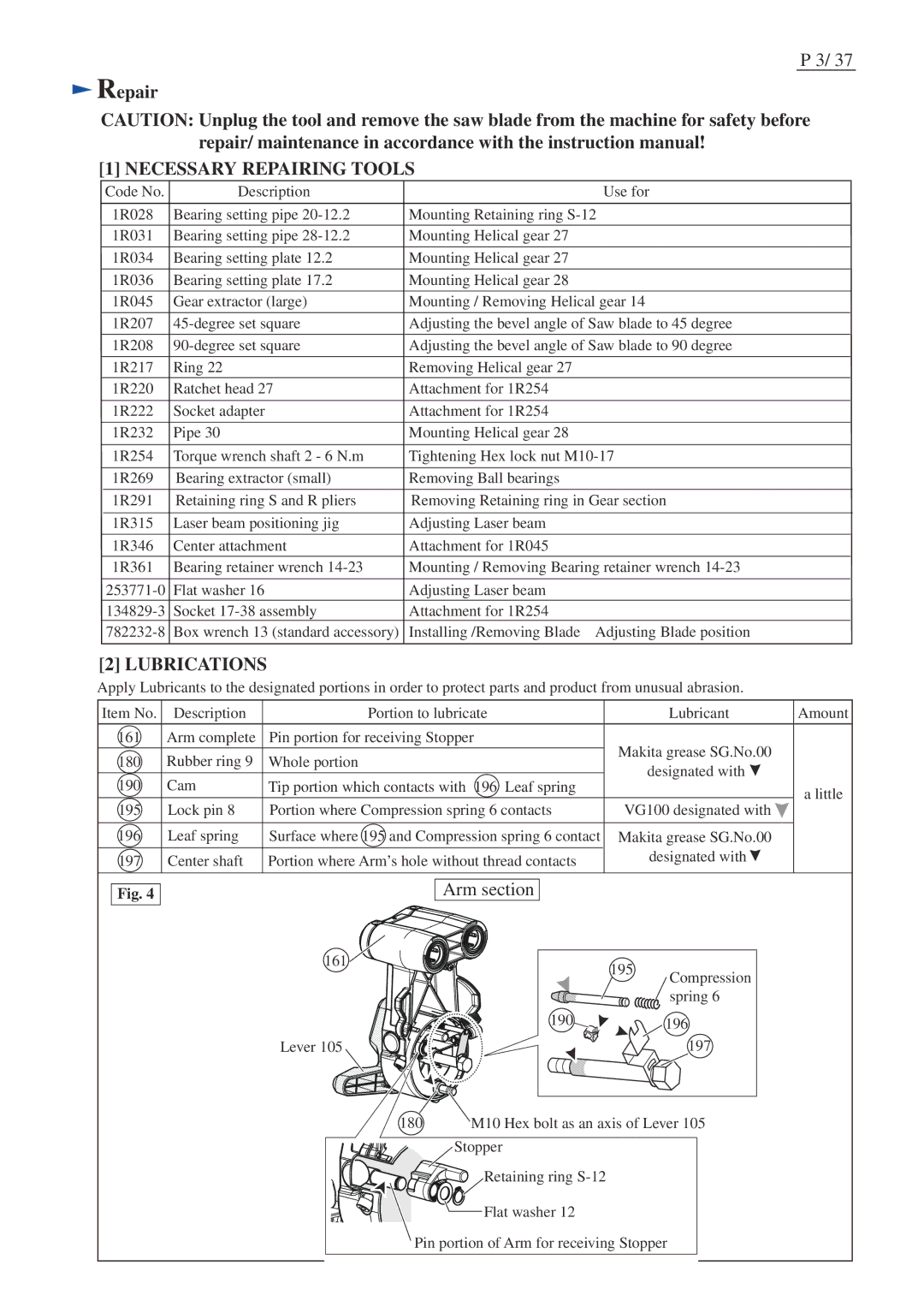

[2] LUBRICATIONS

Apply Lubricants to the designated portions in order to protect parts and product from unusual abrasion.

Item No. | Description | Portion to lubricate | Lubricant | Amount | |

|

|

|

|

| |

161 | Arm complete | Pin portion for receiving Stopper | Makita grease SG.No.00 |

| |

|

|

|

| ||

180 | Rubber ring 9 | Whole portion |

| ||

designated with |

| ||||

|

|

|

| ||

190 | Cam | Tip portion which contacts with 196 Leaf spring | a little | ||

| |||||

|

|

|

| ||

195 | Lock pin 8 | Portion where Compression spring 6 contacts | VG100 designated with | ||

| |||||

|

|

|

|

| |

196 | Leaf spring | Surface where 195 and Compression spring 6 contact | Makita grease SG.No.00 |

| |

197 | Center shaft | Portion where Arm’s hole without thread contacts | designated with |

| |

|

|

|

|

|

Fig. 4

Arm section

161 |

| 195 | Compression |

|

| ||

|

|

| |

|

|

| spring 6 |

| 190 |

| 196 |

Lever 105 |

|

| 197 |

180 | M10 Hex bolt as an axis of Lever 105 | ||

| Stopper |

|

|

| Retaining ring |

|

|

| Flat washer 12 |

|

|

Pin portion of Arm for receiving Stopper