P 3/ 27

Repair

Repair

CAUTION: Remove the bit from the machine for safety before repair/ maintenance in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

Code No. | Description | Use for |

1R030 | Bearing setting pipe | Supporting Pin 6 when assembling shaft lock mechanism |

|

|

|

1R041 | Vise plate | Protecting Armature when holding in vise |

|

|

|

1R268 | Spring pin extractor 3 | Removing Pin 6 of shaft lock mechanism |

1R269 | Bearing extractor | Removing Ball bearing 629DDW |

|

|

|

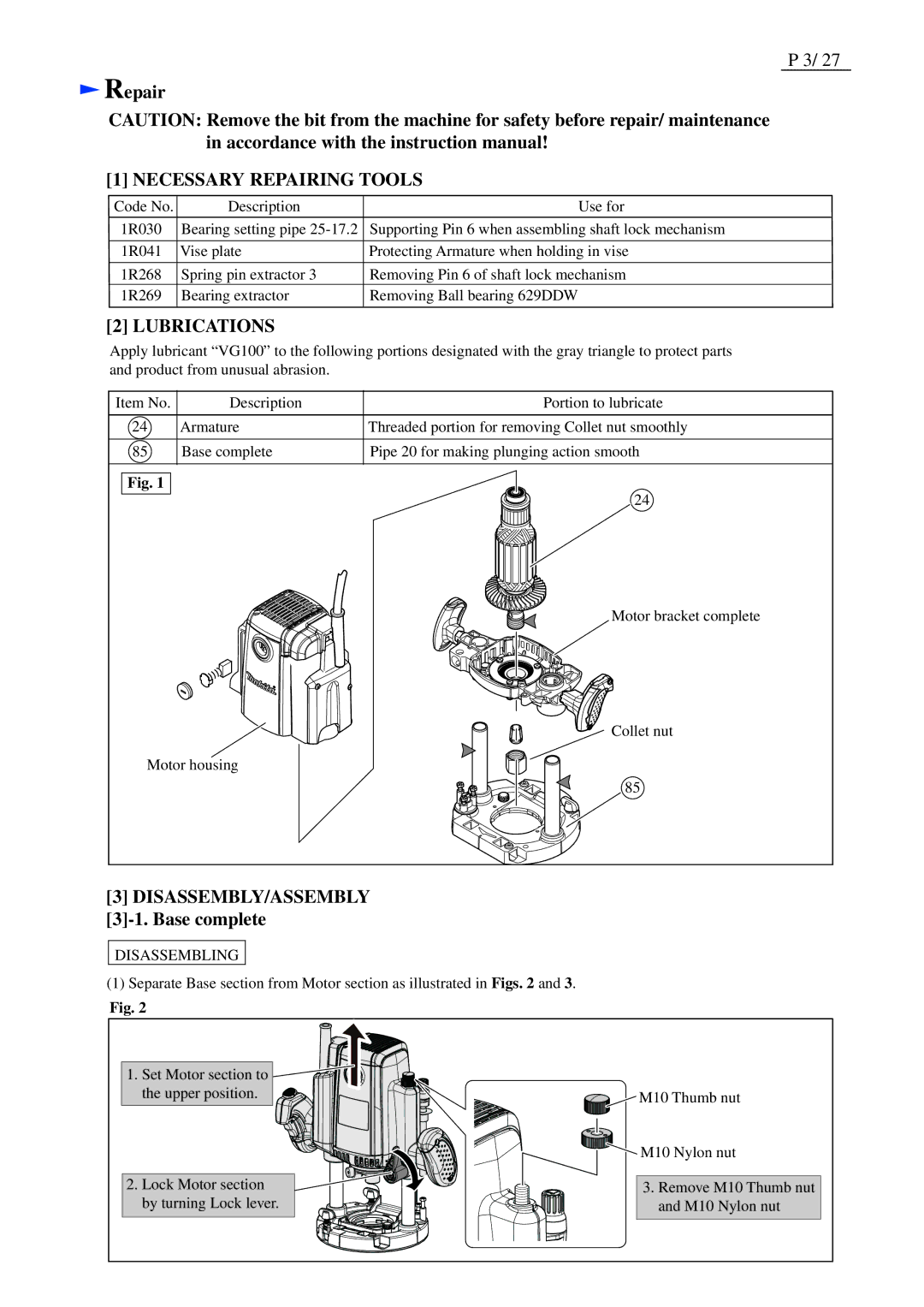

[2] LUBRICATIONS

Apply lubricant “VG100” to the following portions designated with the gray triangle to protect parts and product from unusual abrasion.

Item No. | Description | Portion to lubricate |

24 | Armature | Threaded portion for removing Collet nut smoothly |

85 | Base complete | Pipe 20 for making plunging action smooth |

Fig. 1 |

| 24 |

|

|

Motor bracket complete

Collet nut

Motor housing

85

[3]DISASSEMBLY/ASSEMBLY

[3]-1. Base complete

DISASSEMBLING

(1)Separate Base section from Motor section as illustrated in Figs. 2 and 3.

Fig. 2

1. Set Motor section to ![]() the upper position.

the upper position. ![]()

2. Lock Motor section by turning Lock lever.

![]() M10 Thumb nut

M10 Thumb nut

![]() M10 Nylon nut

M10 Nylon nut

3.Remove M10 Thumb nut and M10 Nylon nut