Section 2 | Installation Instructions |

|

|

Step 5 Pressure Test and Evacuate The Line Set and Remote Condensing Unit

Schrader valve core removal tools that allow for removal and installation of the valve cores without removing manifold gauge set hoses are recommended to decrease the evacuation time.

Leave the line set shut off valves closed (front seated). Pressure test the line sets and remote condensing unit with 150 psig of dry nitrogen. Add nitrogen at the line set shut off valves located at the back of the ice machine. Complete the pressure test, verify no leaks are present and remove the nitrogen from the system before connecting the vacuum pump. Connect a vacuum pump to both of the line set shut off valves located at the back of the ice machine head section. Evacuate to 250 microns (or less). To completely evacuate the Remote condensing unit, continue the evacuation for 30 minutes after reaching the 500 micron point.

CONNECT

VACUUM PUMP TO

LINE SET SHUT

OFF VALVES

SV1757

If required, the line set and condensing unit can be evacuated from the schrader valves located in the remote condensing unit. Schrader valve core removal tools (that allow for putting the cores back in without removing vacuum pump hoses) must be used if evacuating from the condensing unit side.

Isolate the vacuum pump from the line set shut off valves and/or condensing unit access ports prior to proceeding. Open refrigeration system shut off valves.

The suction line, liquid line and receiver service valves are closed during shipment and installation.

ALTERNATE CONNECTIONS AT

CONDENSING UNIT SCHRADER VALVES

SV2085

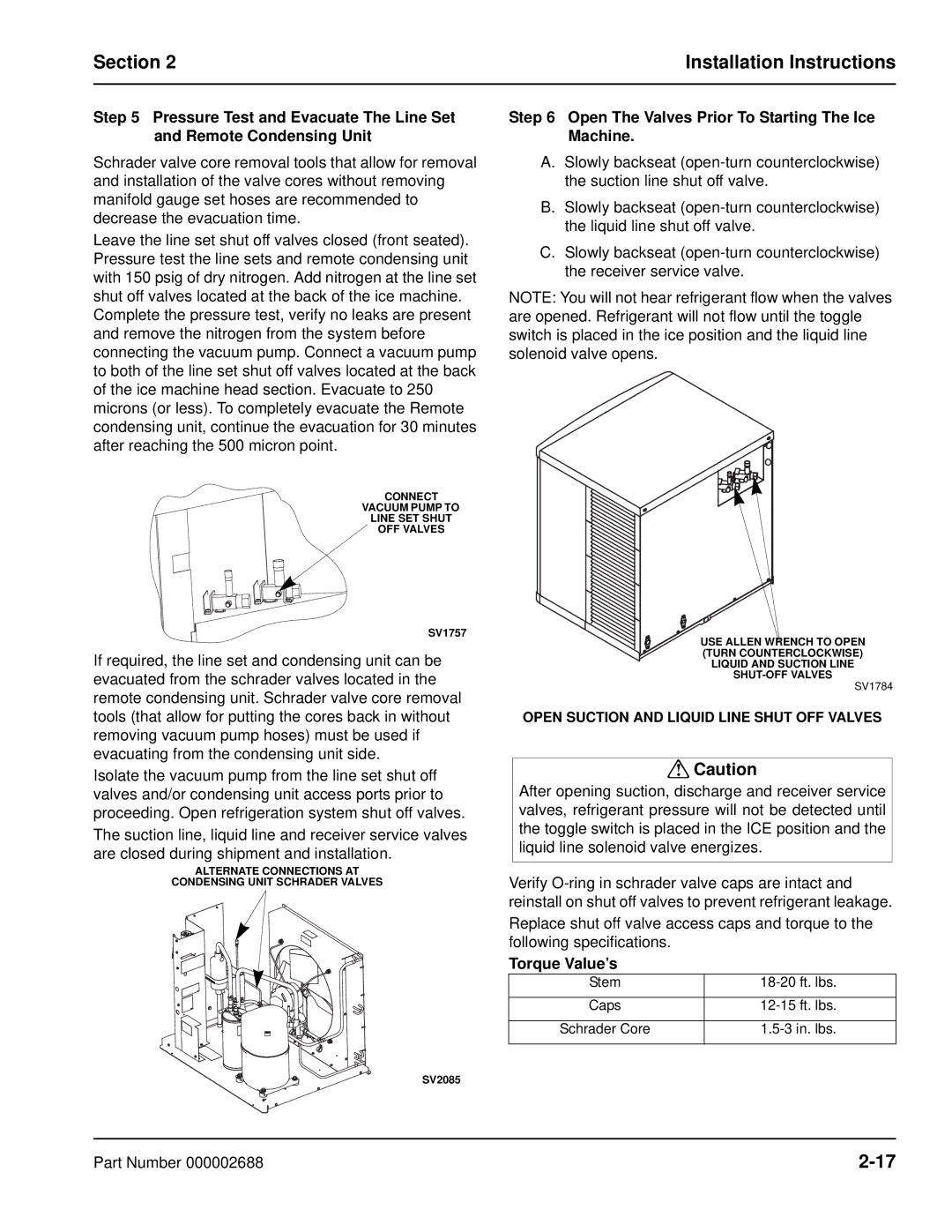

Step 6 Open The Valves Prior To Starting The Ice Machine.

A.Slowly backseat

B.Slowly backseat

C.Slowly backseat

NOTE: You will not hear refrigerant flow when the valves are opened. Refrigerant will not flow until the toggle switch is placed in the ice position and the liquid line solenoid valve opens.

USE ALLEN WRENCH TO OPEN (TURN COUNTERCLOCKWISE)

LIQUID AND SUCTION LINE

SV1784

OPEN SUCTION AND LIQUID LINE SHUT OFF VALVES

!Caution

After opening suction, discharge and receiver service valves, refrigerant pressure will not be detected until the toggle switch is placed in the ICE position and the liquid line solenoid valve energizes.

Verify

Replace shut off valve access caps and torque to the following specifications.

Torque Value’s

Stem | |

Caps | |

Schrader Core |

Part Number 000002688 |