. A complete Parts List is available at www.MillerWelds.com

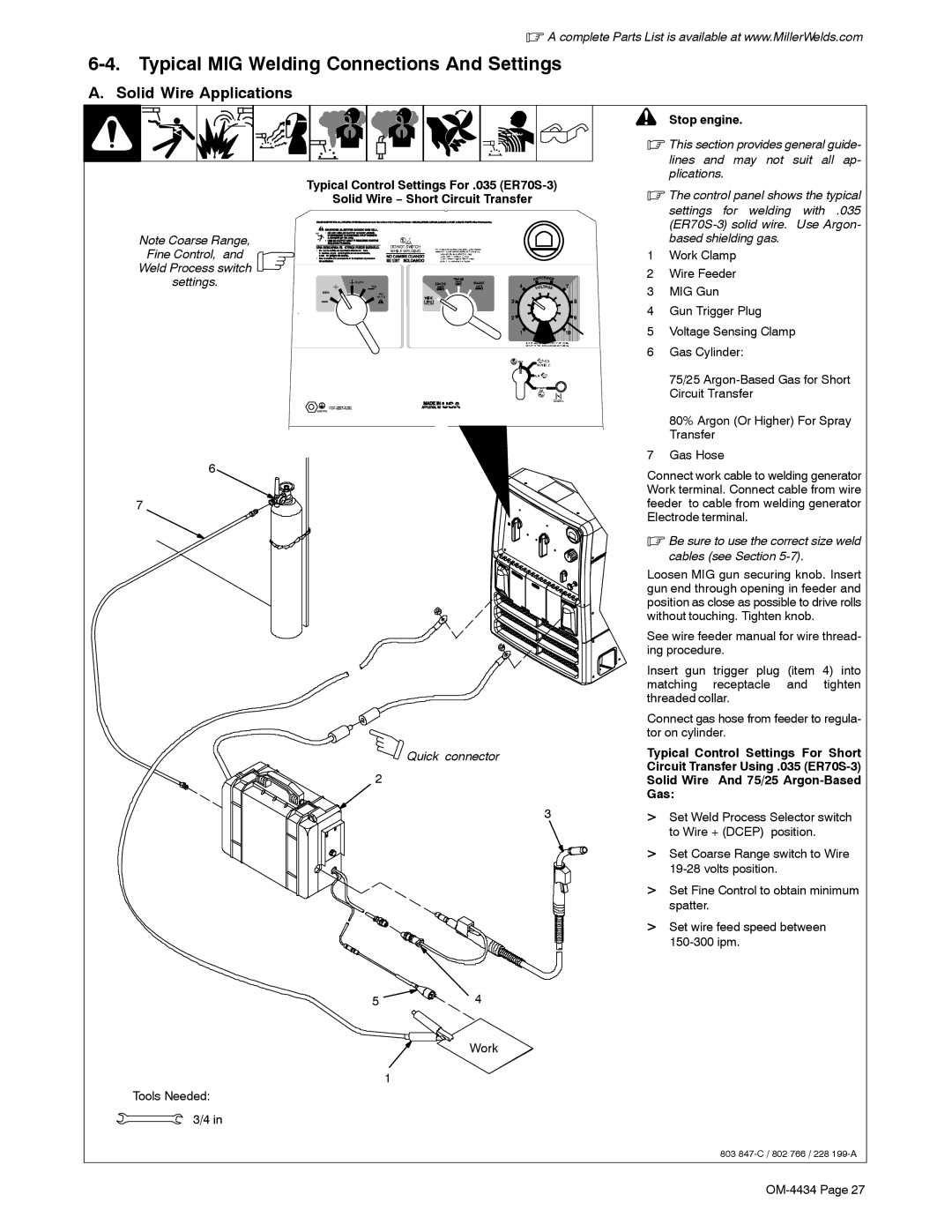

6-4. Typical MIG Welding Connections And Settings

A. Solid Wire Applications

![]() ! Stop engine.

! Stop engine.

Typical Control Settings For .035

Solid Wire − Short Circuit Transfer

Note Coarse Range,

Fine Control, and

Weld Process switch

settings.

6

7

![]() Quick connector

Quick connector

2

3

.This section provides general guide-

lines and may not suit all ap- plications.

.The control panel shows the typical

settings for welding with .035

1Work Clamp

2Wire Feeder

3MIG Gun

4Gun Trigger Plug

5Voltage Sensing Clamp

6Gas Cylinder:

75/25

80% Argon (Or Higher) For Spray Transfer

7Gas Hose

Connect work cable to welding generator Work terminal. Connect cable from wire feeder to cable from welding generator Electrode terminal.

.Be sure to use the correct size weld cables (see Section 5-7).

Loosen MIG gun securing knob. Insert gun end through opening in feeder and position as close as possible to drive rolls without touching. Tighten knob.

See wire feeder manual for wire thread- ing procedure.

Insert gun trigger plug (item 4) into matching receptacle and tighten threaded collar.

Connect gas hose from feeder to regula- tor on cylinder.

Typical Control Settings For Short

Circuit Transfer Using .035

Solid Wire And 75/25

Gas:

>Set Weld Process Selector switch to Wire + (DCEP) position.

>Set Coarse Range switch to Wire

>Set Fine Control to obtain minimum spatter.

>Set wire feed speed between

5 ![]()

![]() 4

4

Work

1

Tools Needed: 3/4 in

803