. Complete Parts List available at www. MillerWelds.com

8-2. Gun Routine Maintenance

Stop engine and dis- connect gun before maintaining.

n = Check | Z = Change | ~ = Clean | l = Replace |

Every

Spool

Of Wire

~ Gun Casing | ~ Nozzle, n Contact Tip |

Every 3

Months

Reference

Section

Section

lCracked Parts

lCracked Parts

lCracked Parts

lCracked Parts

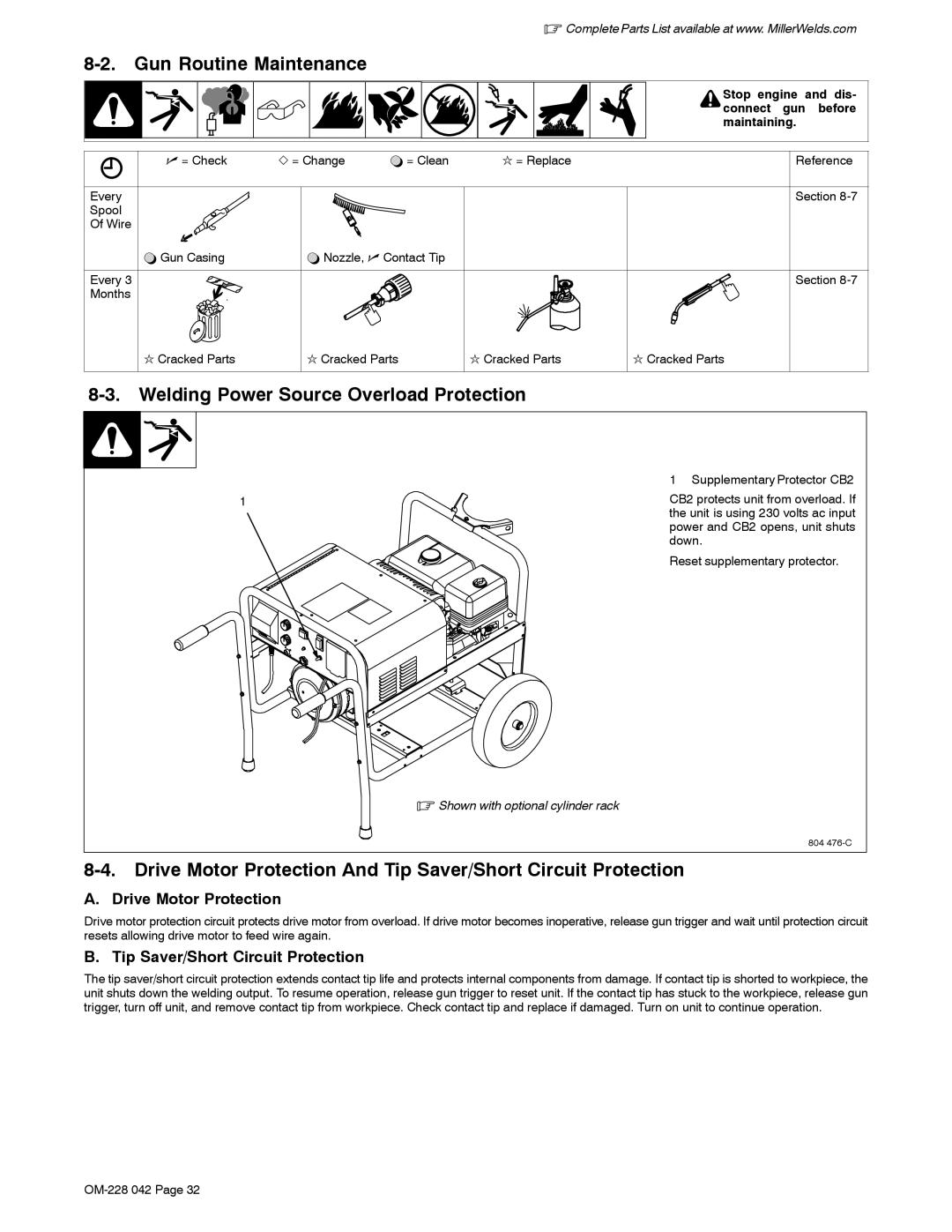

8-3. Welding Power Source Overload Protection

| 1 Supplementary Protector CB2 |

1 | CB2 protects unit from overload. If |

| the unit is using 230 volts ac input |

power and CB2 opens, unit shuts down.

Reset supplementary protector.

.Shown with optional cylinder rack

804

A. Drive Motor Protection

Drive motor protection circuit protects drive motor from overload. If drive motor becomes inoperative, release gun trigger and wait until protection circuit resets allowing drive motor to feed wire again.

B. Tip Saver/Short Circuit Protection

The tip saver/short circuit protection extends contact tip life and protects internal components from damage. If contact tip is shorted to workpiece, the unit shuts down the welding output. To resume operation, release gun trigger to reset unit. If the contact tip has stuck to the workpiece, release gun trigger, turn off unit, and remove contact tip from workpiece. Check contact tip and replace if damaged. Turn on unit to continue operation.