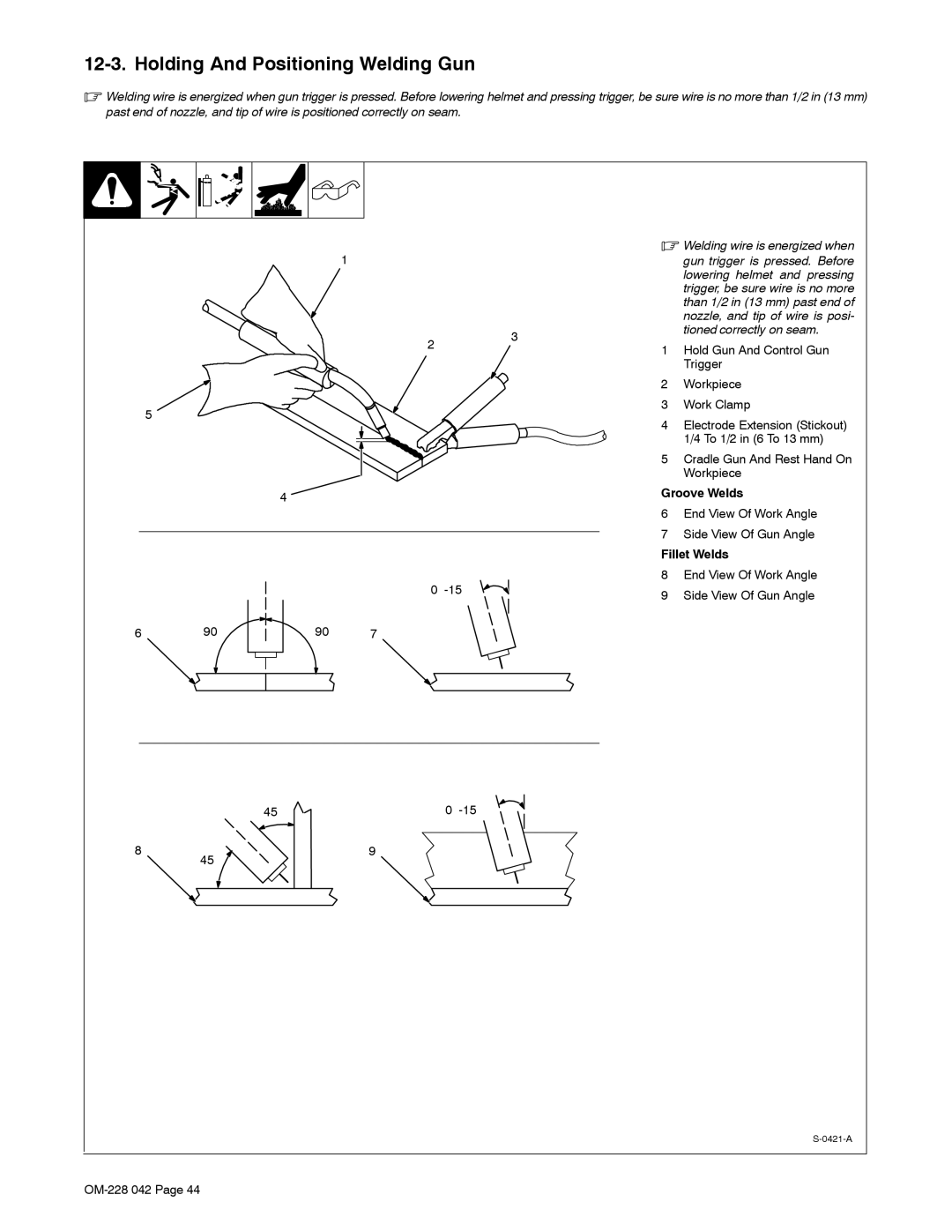

12-3. Holding And Positioning Welding Gun

.Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam.

|

| 1 | . Welding wire is energized when | |

|

|

| gun trigger is pressed. Before | |

|

|

|

| lowering helmet and pressing |

|

|

|

| trigger, be sure wire is no more |

|

|

|

| than 1/2 in (13 mm) past end of |

|

|

|

| nozzle, and tip of wire is posi- |

|

| 2 | 3 | tioned correctly on seam. |

|

|

| ||

|

| 1 | Hold Gun And Control Gun | |

|

|

| ||

|

|

|

| Trigger |

|

|

| 2 | Workpiece |

5 |

|

| 3 | Work Clamp |

|

| 4 | Electrode Extension (Stickout) | |

|

|

| ||

|

|

|

| 1/4 To 1/2 in (6 To 13 mm) |

|

|

| 5 | Cradle Gun And Rest Hand On |

|

|

|

| Workpiece |

| 4 |

| Groove Welds | |

|

|

|

| |

|

|

| 6 | End View Of Work Angle |

|

|

| 7 | Side View Of Gun Angle |

|

|

| Fillet Welds | |

6 90°

8 | End View Of Work Angle | ||

9 | Side View Of Gun Angle | ||

|

90° 7

| ° | |

| 45 |

|

8 | 45° | 9 |

|

|