| . Complete Parts List available at www. MillerWelds.com | |

|

| |

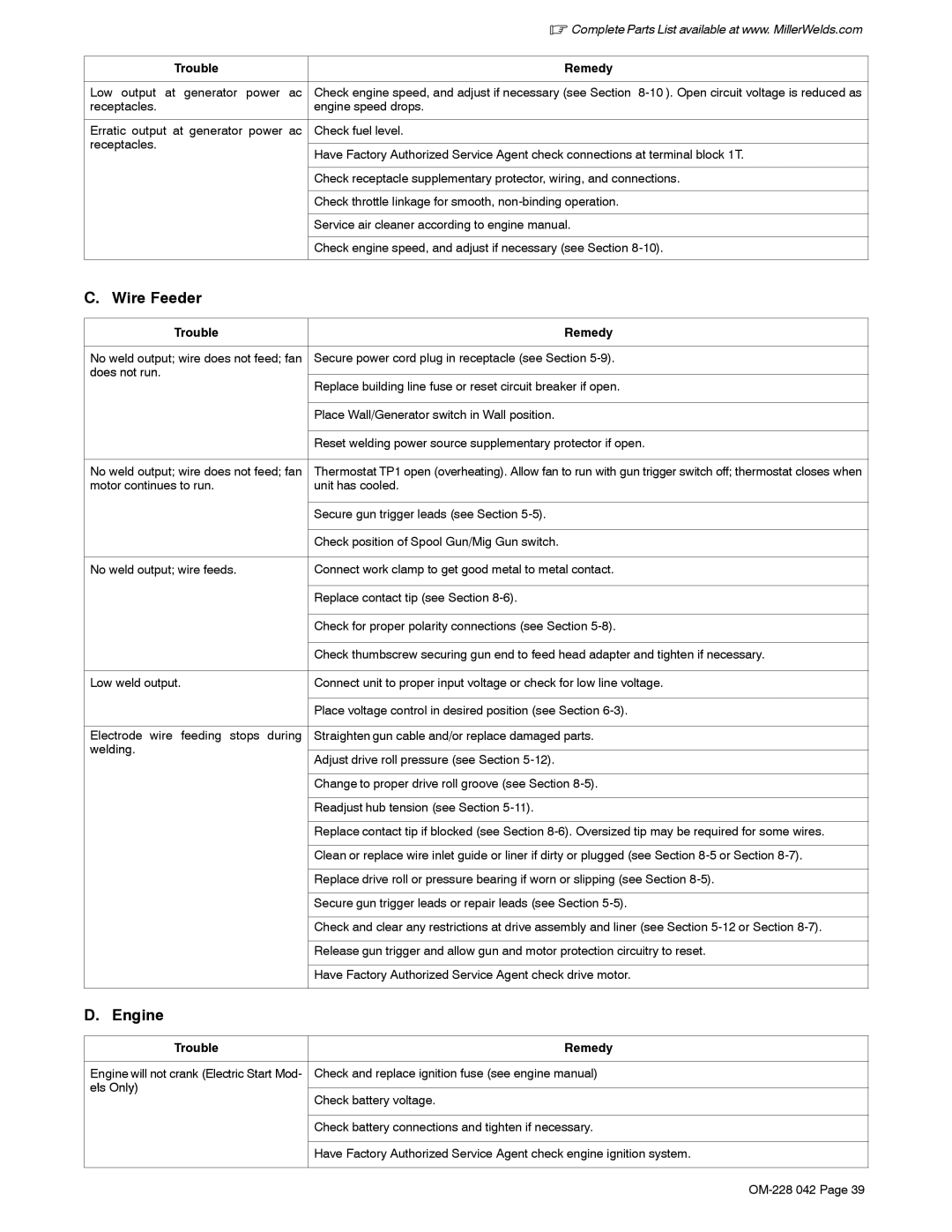

Trouble | Remedy | |

|

| |

Low output at generator power ac | Check engine speed, and adjust if necessary (see Section | |

receptacles. | engine speed drops. | |

|

| |

Erratic output at generator power ac | Check fuel level. | |

receptacles. |

| |

Have Factory Authorized Service Agent check connections at terminal block 1T. | ||

| ||

|

| |

| Check receptacle supplementary protector, wiring, and connections. | |

|

| |

| Check throttle linkage for smooth, | |

|

| |

| Service air cleaner according to engine manual. | |

|

| |

| Check engine speed, and adjust if necessary (see Section | |

|

| |

C. Wire Feeder |

| |

|

| |

Trouble | Remedy | |

|

| |

No weld output; wire does not feed; fan | Secure power cord plug in receptacle (see Section | |

does not run. |

| |

Replace building line fuse or reset circuit breaker if open. | ||

| ||

|

| |

| Place Wall/Generator switch in Wall position. | |

|

| |

| Reset welding power source supplementary protector if open. | |

|

| |

No weld output; wire does not feed; fan | Thermostat TP1 open (overheating). Allow fan to run with gun trigger switch off; thermostat closes when | |

motor continues to run. | unit has cooled. | |

|

| |

| Secure gun trigger leads (see Section | |

|

| |

| Check position of Spool Gun/Mig Gun switch. | |

|

| |

No weld output; wire feeds. | Connect work clamp to get good metal to metal contact. | |

|

| |

| Replace contact tip (see Section | |

|

| |

| Check for proper polarity connections (see Section | |

|

| |

| Check thumbscrew securing gun end to feed head adapter and tighten if necessary. | |

|

| |

Low weld output. | Connect unit to proper input voltage or check for low line voltage. | |

|

| |

| Place voltage control in desired position (see Section | |

|

| |

Electrode wire feeding stops during | Straighten gun cable and/or replace damaged parts. | |

welding. |

| |

Adjust drive roll pressure (see Section | ||

| ||

|

| |

| Change to proper drive roll groove (see Section | |

|

| |

| Readjust hub tension (see Section | |

|

| |

| Replace contact tip if blocked (see Section | |

|

| |

| Clean or replace wire inlet guide or liner if dirty or plugged (see Section | |

|

| |

| Replace drive roll or pressure bearing if worn or slipping (see Section | |

|

| |

| Secure gun trigger leads or repair leads (see Section | |

|

| |

| Check and clear any restrictions at drive assembly and liner (see Section | |

|

| |

| Release gun trigger and allow gun and motor protection circuitry to reset. | |

|

| |

| Have Factory Authorized Service Agent check drive motor. | |

|

| |

D. Engine |

| |

|

| |

Trouble | Remedy | |

|

| |

Engine will not crank (Electric Start Mod- | Check and replace ignition fuse (see engine manual) | |

els Only) |

| |

Check battery voltage. | ||

| ||

|

| |

| Check battery connections and tighten if necessary. | |

|

| |

| Have Factory Authorized Service Agent check engine ignition system. | |

|

| |

|

Page 43

Image 43