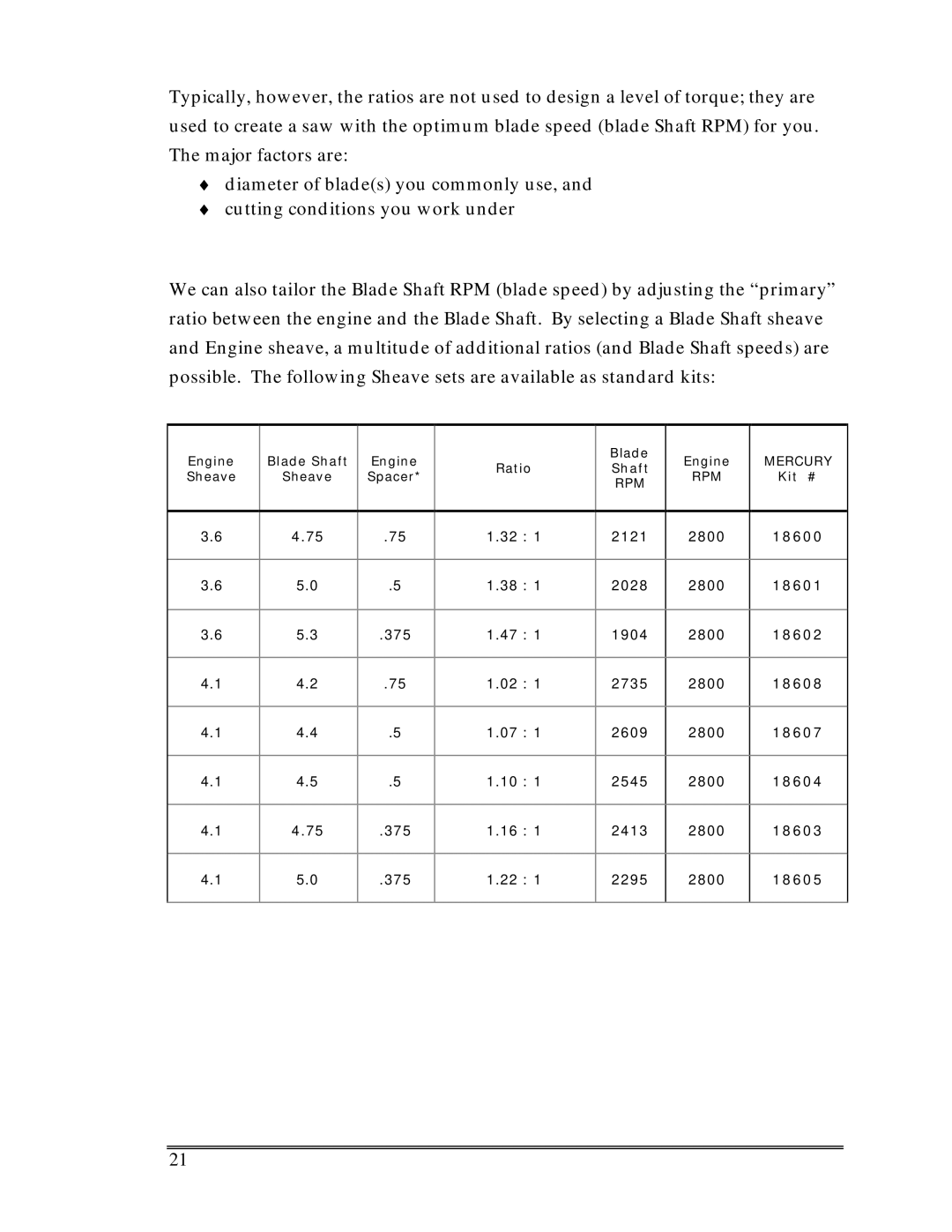

Typically, however, the ratios are not used to design a level of torque; they are used to create a saw with the optimum blade speed (blade Shaft RPM) for you. The major factors are:

♦diameter of blade(s) you commonly use, and

♦cutting conditions you work under

We can also tailor the Blade Shaft RPM (blade speed) by adjusting the “primary” ratio between the engine and the Blade Shaft. By selecting a Blade Shaft sheave and Engine sheave, a multitude of additional ratios (and Blade Shaft speeds) are possible. The following Sheave sets are available as standard kits:

Engine | Blade Shaft | Engine |

| Blade | Engine | MERCURY | |

Ratio | Shaft | ||||||

Sheave | Sheave | Spacer* | RPM | Kit # | |||

| RPM | ||||||

|

|

|

|

|

| ||

|

|

|

|

|

|

|

3.6 | 4.75 | .75 | 1.32 : 1 | 2121 | 2800 | 18600 |

|

|

|

|

|

|

|

3.6 | 5.0 | .5 | 1.38 : 1 | 2028 | 2800 | 18601 |

|

|

|

|

|

|

|

3.6 | 5.3 | .375 | 1.47 : 1 | 1904 | 2800 | 18602 |

|

|

|

|

|

|

|

4.1 | 4.2 | .75 | 1.02 : 1 | 2735 | 2800 | 18608 |

|

|

|

|

|

|

|

4.1 | 4.4 | .5 | 1.07 : 1 | 2609 | 2800 | 18607 |

|

|

|

|

|

|

|

4.1 | 4.5 | .5 | 1.10 : 1 | 2545 | 2800 | 18604 |

|

|

|

|

|

|

|

4.1 | 4.75 | .375 | 1.16 : 1 | 2413 | 2800 | 18603 |

|

|

|

|

|

|

|

4.1 | 5.0 | .375 | 1.22 : 1 | 2295 | 2800 | 18605 |

|

|

|

|

|

|

|

21