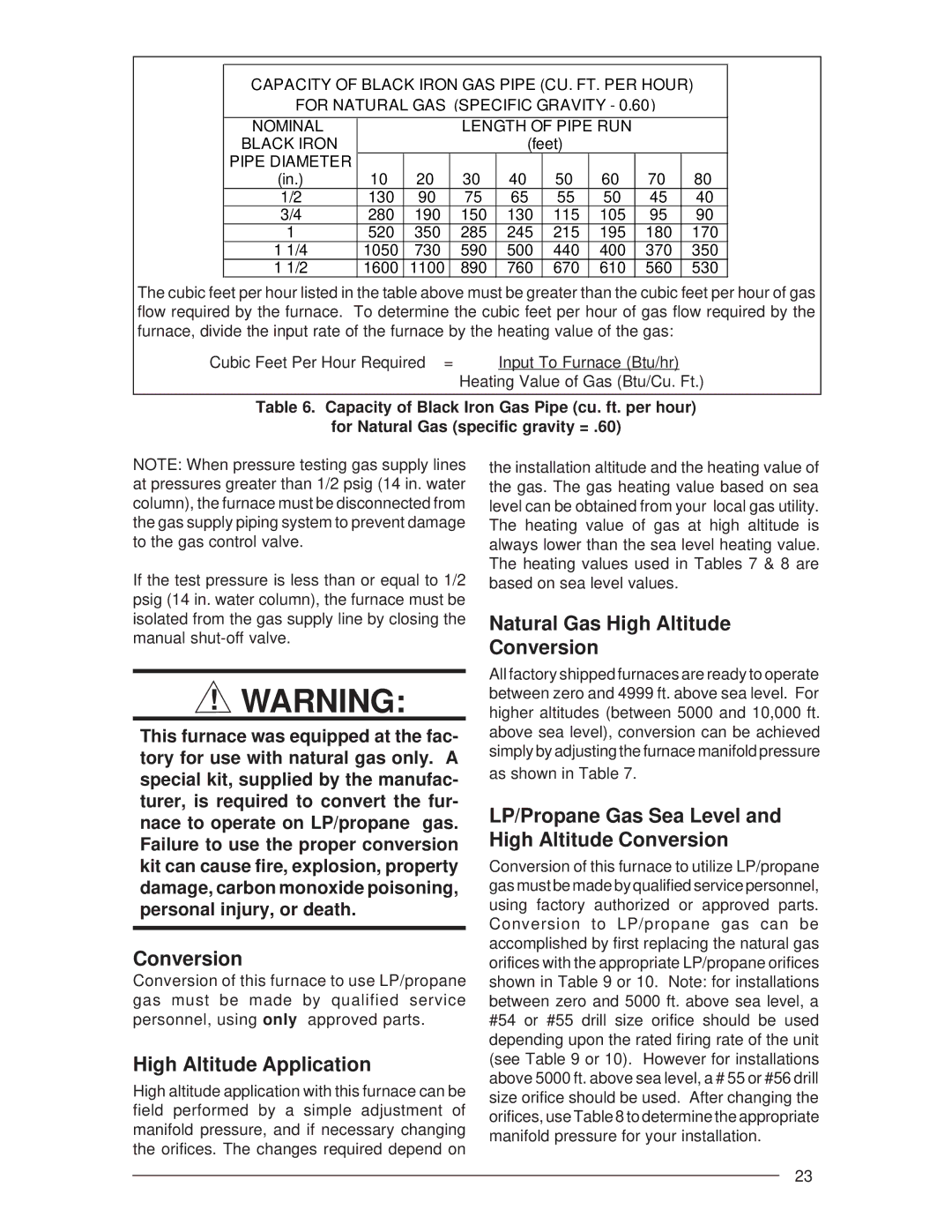

CAPACITY OF BLACK IRON GAS PIPE (CU. FT. PER HOUR)

FOR NATURAL GAS (SPECIFIC GRAVITY - 0.60)

| NOMINAL |

|

| LENGTH OF PIPE RUN |

|

| ||||

| BLACK IRON |

|

|

| (feet) |

|

|

| ||

| PIPE DIAMETER |

|

|

|

|

|

|

|

| |

| (in.) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | |

1/2 | 130 | 90 | 75 | 65 | 55 | 50 | 45 | 40 | ||

| 3/4 | 280 | 190 | 150 | 130 | 115 | 105 | 95 | 90 | |

|

| 1 | 520 | 350 | 285 | 245 | 215 | 195 | 180 | 170 |

| 1 | 1/4 | 1050 | 730 | 590 | 500 | 440 | 400 | 370 | 350 |

| 1 | 1/2 | 1600 | 1100 | 890 | 760 | 670 | 610 | 560 | 530 |

The cubic feet per hour listed in the table above must be greater than the cubic feet per hour of gas flow required by the furnace. To determine the cubic feet per hour of gas flow required by the furnace, divide the input rate of the furnace by the heating value of the gas:

Cubic Feet Per Hour Required = | Input To Furnace (Btu/hr) |

| Heating Value of Gas (Btu/Cu. Ft.) |

Table 6. Capacity of Black Iron Gas Pipe (cu. ft. per hour)

for Natural Gas (specific gravity = .60)

NOTE: When pressure testing gas supply lines at pressures greater than 1/2 psig (14 in. water column), the furnace must be disconnected from the gas supply piping system to prevent damage to the gas control valve.

If the test pressure is less than or equal to 1/2 psig (14 in. water column), the furnace must be isolated from the gas supply line by closing the manual

!WARNING:

This furnace was equipped at the fac- tory for use with natural gas only. A special kit, supplied by the manufac- turer, is required to convert the fur- nace to operate on LP/propane gas. Failure to use the proper conversion kit can cause fire, explosion, property damage, carbon monoxide poisoning, personal injury, or death.

Conversion

Conversion of this furnace to use LP/propane gas must be made by qualified service personnel, using only approved parts.

High Altitude Application

High altitude application with this furnace can be field performed by a simple adjustment of manifold pressure, and if necessary changing the orifices. The changes required depend on

the installation altitude and the heating value of the gas. The gas heating value based on sea level can be obtained from your local gas utility. The heating value of gas at high altitude is always lower than the sea level heating value. The heating values used in Tables 7 & 8 are based on sea level values.

Natural Gas High Altitude

Conversion

All factory shipped furnaces are ready to operate between zero and 4999 ft. above sea level. For higher altitudes (between 5000 and 10,000 ft. above sea level), conversion can be achieved simply by adjusting the furnace manifold pressure as shown in Table 7.

LP/Propane Gas Sea Level and High Altitude Conversion

Conversion of this furnace to utilize LP/propane gas must be made by qualified service personnel, using factory authorized or approved parts. Conversion to LP/propane gas can be accomplished by first replacing the natural gas orifices with the appropriate LP/propane orifices shown in Table 9 or 10. Note: for installations between zero and 5000 ft. above sea level, a #54 or #55 drill size orifice should be used depending upon the rated firing rate of the unit (see Table 9 or 10). However for installations above 5000 ft. above sea level, a # 55 or #56 drill size orifice should be used. After changing the orifices, use Table 8 to determine the appropriate manifold pressure for your installation.

23