Note: Full instructions are provided in the Filling Loop Kit pack.

| 10.0 Installation | ||

|

|

|

|

|

|

|

|

10.3 | Fitting the Filling Loop Kit | ||

1. The filling loop kit supplied with the boiler can be | |||

connected to the taps on the wall plate at this point. | |||

(Either one of two types of loop kit will be supplied - | |||

both function in the same way, differing only in detail). | |||

2. The filling loop is to be connected between the mains | |||

cold water inlet and central heating return isolation taps. | |||

3. The loop and valves must be connected as described | |||

in the instructions supplied with it. | |||

4. Note the orientation of the flow direction arrows on | |||

the stop valve and double check/stop valves. | |||

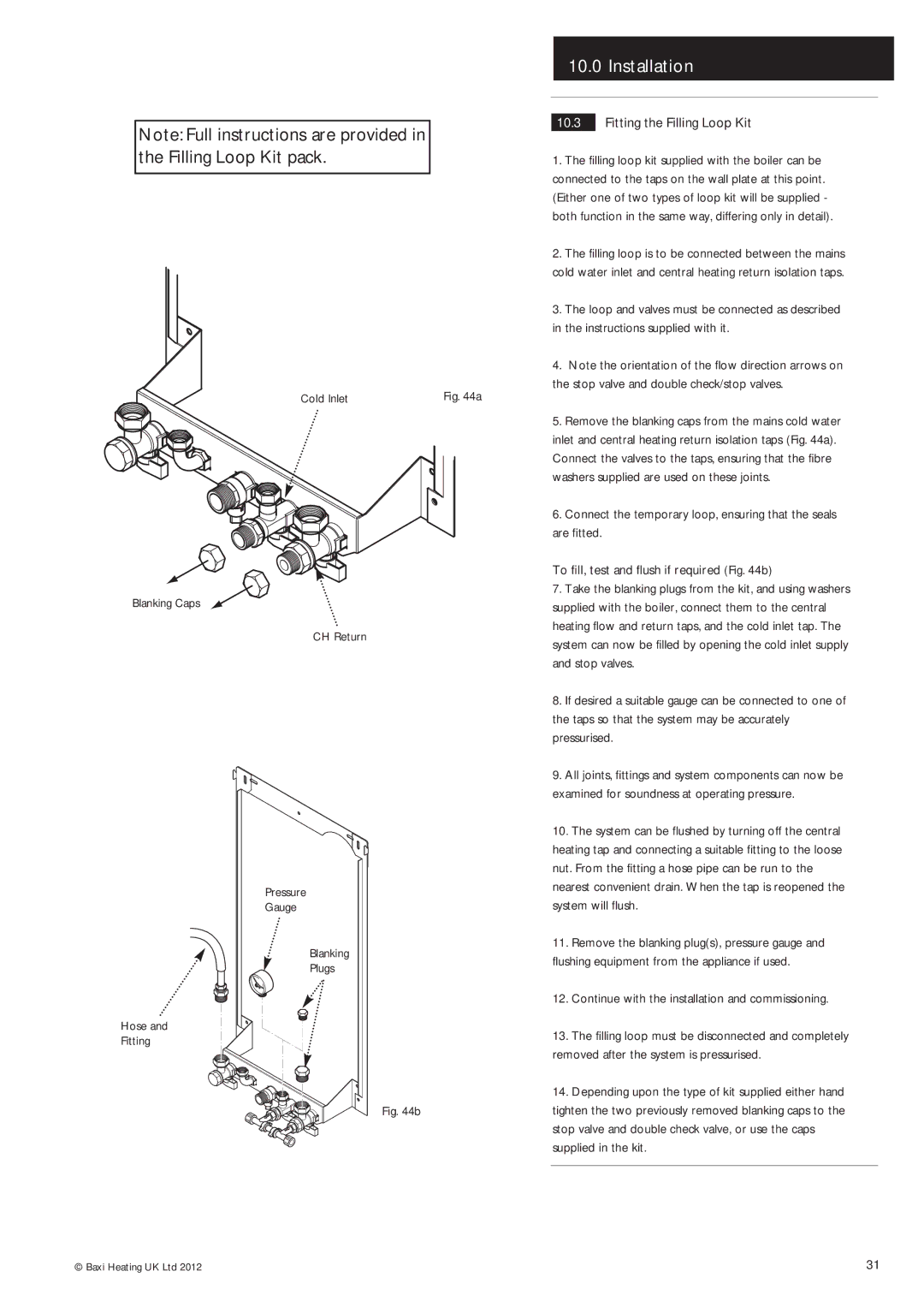

Blanking Caps

Hose and

Fitting

Cold Inlet | Fig. 44a |

CH Return

Pressure

Gauge

Blanking

Plugs

5. Remove the blanking caps from the mains cold water |

inlet and central heating return isolation taps (Fig. 44a). |

Connect the valves to the taps, ensuring that the fibre |

washers supplied are used on these joints. |

6. Connect the temporary loop, ensuring that the seals |

are fitted. |

To fill, test and flush if required (Fig. 44b)

7. Take the blanking plugs from the kit, and using washers | |

supplied with the boiler, connect them to the central | |

heating flow and return taps, and the cold inlet tap. The | |

system can now be filled by opening the cold inlet supply | |

and stop valves. | |

8. If desired a suitable gauge can be connected to one of | |

the taps so that the system may be accurately | |

pressurised. | |

9. All joints, fittings and system components can now be | |

examined for soundness at operating pressure. | |

10. | The system can be flushed by turning off the central |

heating tap and connecting a suitable fitting to the loose | |

nut. From the fitting a hose pipe can be run to the | |

nearest convenient drain. When the tap is reopened the | |

system will flush. | |

11. | Remove the blanking plug(s), pressure gauge and |

flushing equipment from the appliance if used. | |

12. | Continue with the installation and commissioning. |

13. | The filling loop must be disconnected and completely |

removed after the system is pressurised. | |

14. | Depending upon the type of kit supplied either hand |

Fig. 44b

tighten the two previously removed blanking caps to the |

stop valve and double check valve, or use the caps |

supplied in the kit. |

© Baxi Heating UK Ltd 2012 | 31 |