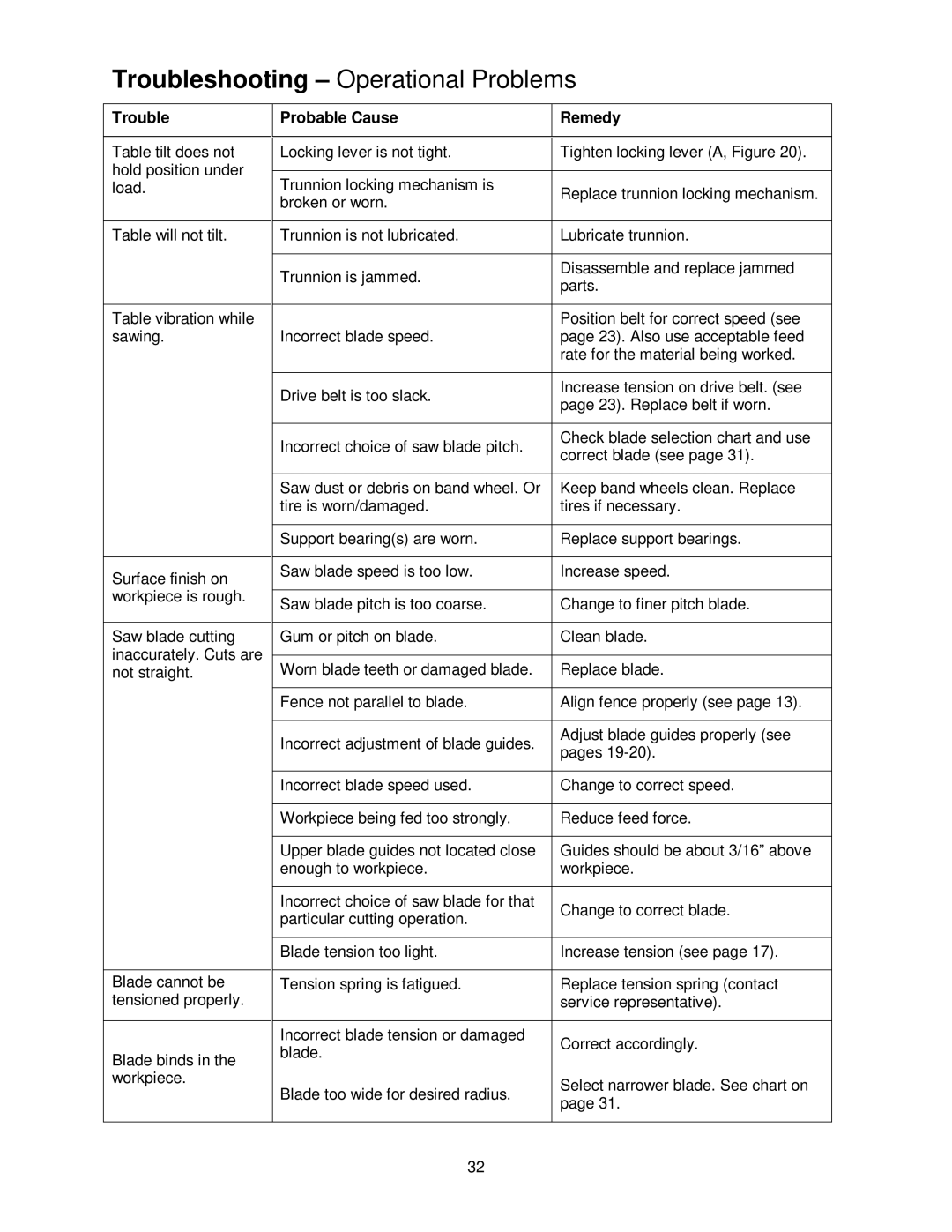

Troubleshooting – Operational Problems

Trouble

Table tilt does not hold position under load.

Table will not tilt.

Table vibration while sawing.

Surface finish on workpiece is rough.

Saw blade cutting inaccurately. Cuts are not straight.

Blade cannot be tensioned properly.

Blade binds in the workpiece.

Probable Cause | Remedy | |

|

| |

Locking lever is not tight. | Tighten locking lever (A, Figure 20). | |

|

| |

Trunnion locking mechanism is | Replace trunnion locking mechanism. | |

broken or worn. | ||

| ||

|

| |

Trunnion is not lubricated. | Lubricate trunnion. | |

|

| |

Trunnion is jammed. | Disassemble and replace jammed | |

parts. | ||

| ||

|

| |

| Position belt for correct speed (see | |

Incorrect blade speed. | page 23). Also use acceptable feed | |

| rate for the material being worked. | |

|

| |

Drive belt is too slack. | Increase tension on drive belt. (see | |

page 23). Replace belt if worn. | ||

| ||

|

| |

Incorrect choice of saw blade pitch. | Check blade selection chart and use | |

correct blade (see page 31). | ||

| ||

|

| |

Saw dust or debris on band wheel. Or | Keep band wheels clean. Replace | |

tire is worn/damaged. | tires if necessary. | |

|

| |

Support bearing(s) are worn. | Replace support bearings. | |

|

| |

Saw blade speed is too low. | Increase speed. | |

|

| |

Saw blade pitch is too coarse. | Change to finer pitch blade. | |

|

| |

Gum or pitch on blade. | Clean blade. | |

|

| |

Worn blade teeth or damaged blade. | Replace blade. | |

|

| |

Fence not parallel to blade. | Align fence properly (see page 13). | |

|

| |

Incorrect adjustment of blade guides. | Adjust blade guides properly (see | |

pages | ||

| ||

|

| |

Incorrect blade speed used. | Change to correct speed. | |

|

| |

Workpiece being fed too strongly. | Reduce feed force. | |

|

| |

Upper blade guides not located close | Guides should be about 3/16” above | |

enough to workpiece. | workpiece. | |

|

| |

Incorrect choice of saw blade for that | Change to correct blade. | |

particular cutting operation. | ||

| ||

|

| |

Blade tension too light. | Increase tension (see page 17). | |

|

| |

Tension spring is fatigued. | Replace tension spring (contact | |

| service representative). | |

|

| |

Incorrect blade tension or damaged | Correct accordingly. | |

blade. | ||

| ||

|

| |

Blade too wide for desired radius. | Select narrower blade. See chart on | |

page 31. | ||

| ||

|

|

32