The measurement should be the same at both ends of the rear rail. Adjust as needed.

3.Tighten the three screws with a 12mm wrench.

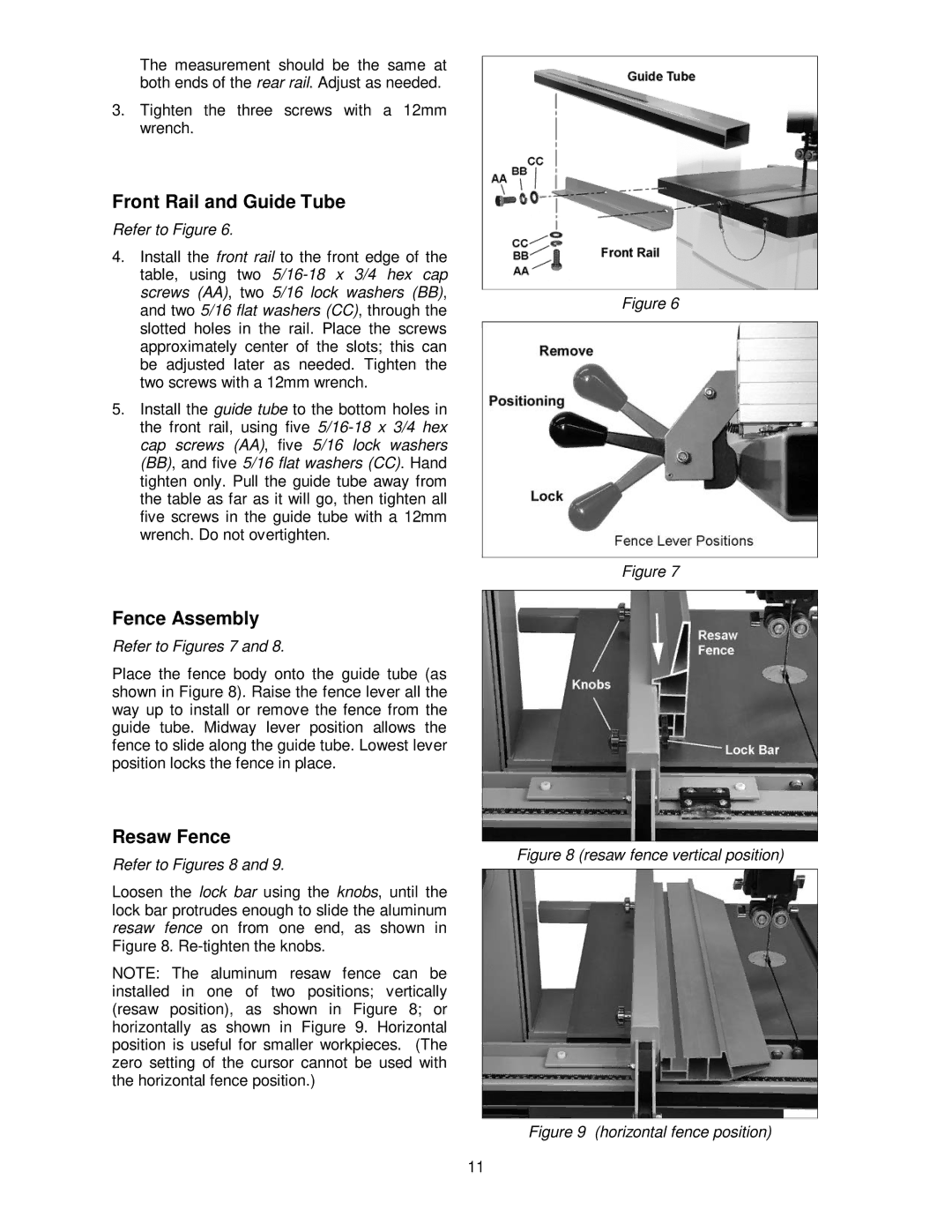

Front Rail and Guide Tube

Refer to Figure 6.

4.Install the front rail to the front edge of the table, using two

5.Install the guide tube to the bottom holes in the front rail, using five

Fence Assembly

Refer to Figures 7 and 8.

Place the fence body onto the guide tube (as shown in Figure 8). Raise the fence lever all the way up to install or remove the fence from the guide tube. Midway lever position allows the fence to slide along the guide tube. Lowest lever position locks the fence in place.

Resaw Fence

Refer to Figures 8 and 9.

Loosen the lock bar using the knobs, until the lock bar protrudes enough to slide the aluminum resaw fence on from one end, as shown in Figure 8.

NOTE: The aluminum resaw fence can be installed in one of two positions; vertically (resaw position), as shown in Figure 8; or horizontally as shown in Figure 9. Horizontal position is useful for smaller workpieces. (The zero setting of the cursor cannot be used with the horizontal fence position.)

Figure 6

Figure 7

Figure 8 (resaw fence vertical position)

Figure 9 (horizontal fence position)

11