Installation

Tools required for assembly and set up:

7/32” hex (Allen) wrench 6mm hex (Allen) wrench 12mm

Hoist or forklift, with straps

Remove all crating and plastic from around the machine. Remove any screws or straps holding the band saw to the shipping pallet.

![]() Exercise care when removing the machine from the shipping pallet.

Exercise care when removing the machine from the shipping pallet.

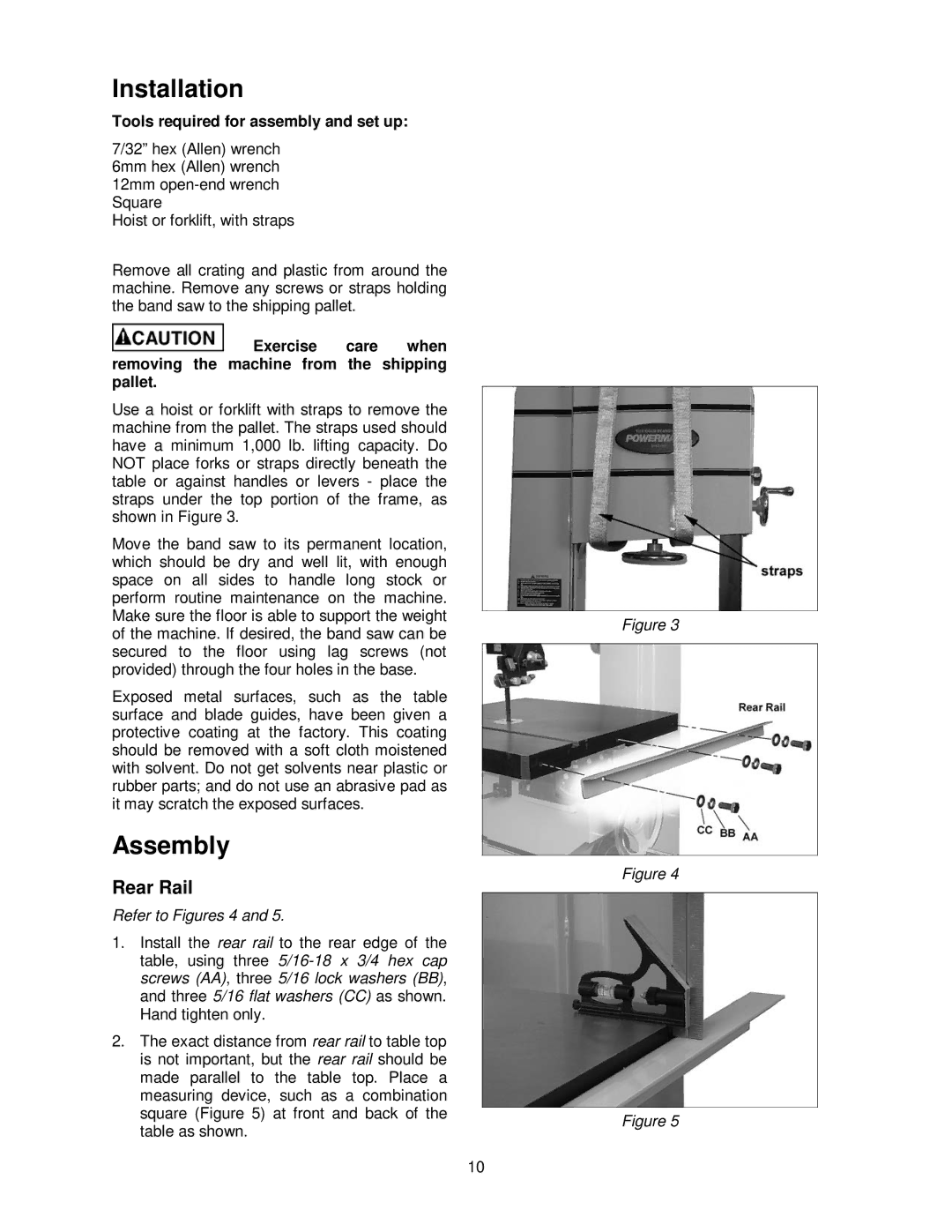

Use a hoist or forklift with straps to remove the machine from the pallet. The straps used should have a minimum 1,000 lb. lifting capacity. Do NOT place forks or straps directly beneath the table or against handles or levers - place the straps under the top portion of the frame, as shown in Figure 3.

Move the band saw to its permanent location, which should be dry and well lit, with enough space on all sides to handle long stock or perform routine maintenance on the machine. Make sure the floor is able to support the weight of the machine. If desired, the band saw can be secured to the floor using lag screws (not provided) through the four holes in the base.

Exposed metal surfaces, such as the table surface and blade guides, have been given a protective coating at the factory. This coating should be removed with a soft cloth moistened with solvent. Do not get solvents near plastic or rubber parts; and do not use an abrasive pad as it may scratch the exposed surfaces.

Assembly

Rear Rail

Refer to Figures 4 and 5.

1.Install the rear rail to the rear edge of the table, using three

2.The exact distance from rear rail to table top is not important, but the rear rail should be made parallel to the table top. Place a measuring device, such as a combination square (Figure 5) at front and back of the table as shown.

10

Figure 3

Figure 4

Figure 5