EST150

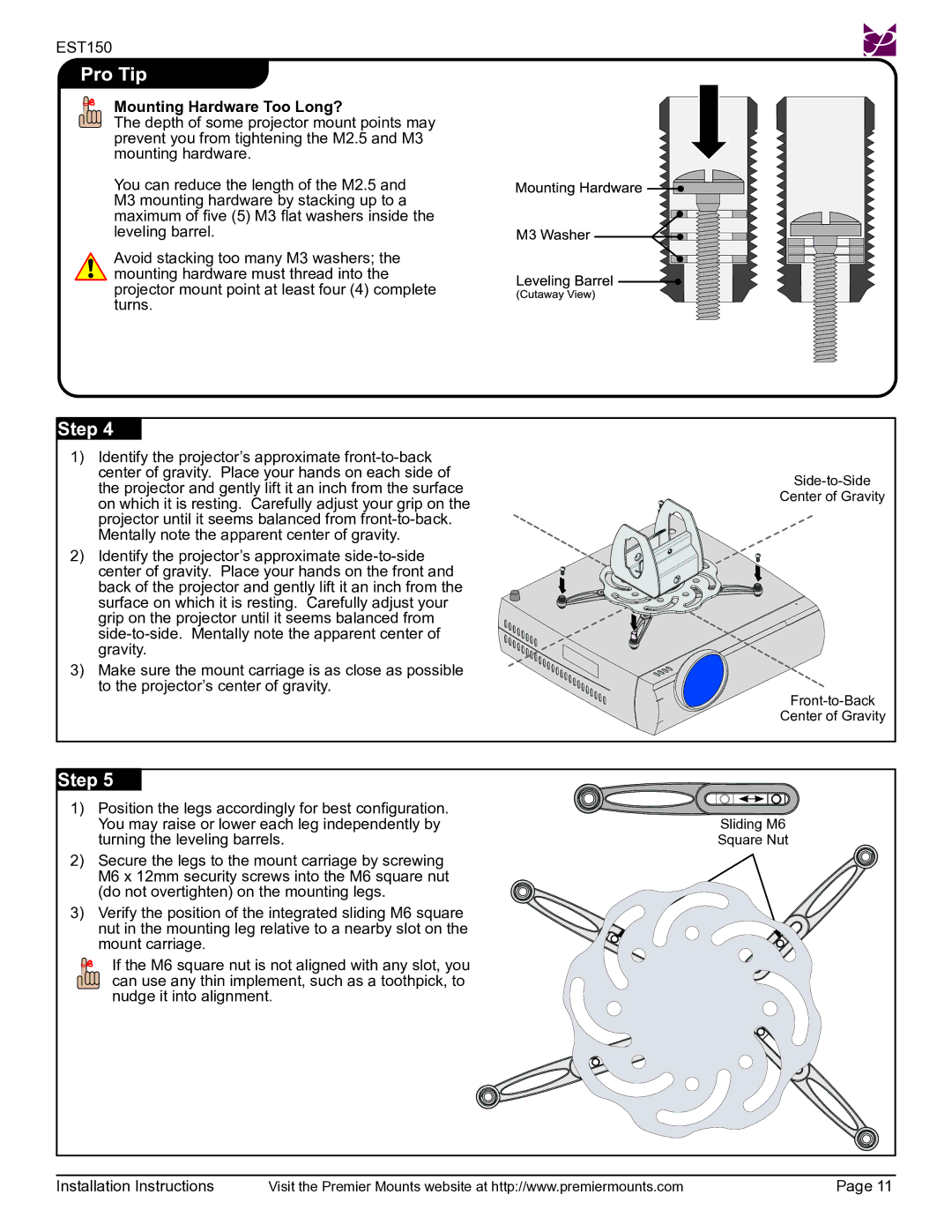

Mounting Hardware Too Long?

The depth of some projector mount points may prevent you from tightening the M2.5 and M3 mounting hardware.

You can reduce the length of the M2.5 and

M3 mounting hardware by stacking up to a maximum of five (5) M3 flat washers inside the leveling barrel.

Avoid stacking too many M3 washers; the mounting hardware must thread into the projector mount point at least four (4) complete turns.

Step 4

1)Identify the projector’s approximate

2)Identify the projector’s approximate

3)Make sure the mount carriage is as close as possible to the projector’s center of gravity.

Center of Gravity

Center of Gravity

Step 5

1) Position the legs accordingly for best configuration. |

|

You may raise or lower each leg independently by | Sliding M6 |

turning the leveling barrels. | Square Nut |

2)Secure the legs to the mount carriage by screwing

M6 x 12mm security screws into the M6 square nut (do not overtighten) on the mounting legs.

3)Verify the position of the integrated sliding M6 square nut in the mounting leg relative to a nearby slot on the mount carriage.

If the M6 square nut is not aligned with any slot, you can use any thin implement, such as a toothpick, to nudge it into alignment.

Installation Instructions | Visit the Premier Mounts website at http://www.premiermounts.com | Page 11 |