Adjustment & Replacement of Components

Gas Valve Replacement

1.

2.Remove gas piping to gas valve inlet.

3.Disconnect wiring connections, pilot tubing (when present).

4.Remove screws (2) holding the burner tray.

5.Slide burner tray out.

6.Remove gas valve bracket screws and bracket.

7.Unscrew gas valve from gas pipe.

8.Reverse above procedure to

Pilot Burner Cleaning or Replacement (Standing Pilot)

1.

2.Disconnect gas piping to gas valve.

3.Disconnect wiring connections to gas valve.

4.Remove screws (2) holding the burner tray.

5.Slide burner tray out.

6.Remove screw holding pilot lighter tube.

7.Remove screws (2) holding pilot bracket on the burner tray.

8.Disconnect thermocouple and pilot tubing from the gas valve.

9.Remove pilot burner from pilot bracket.

10.Remove pilot orifice and blow away lint or dirt. Clean with wire or small brush. NOTE: Make sure pilot orifice is clear, but do not enlarge the hole.

11.Reverse above procedure to

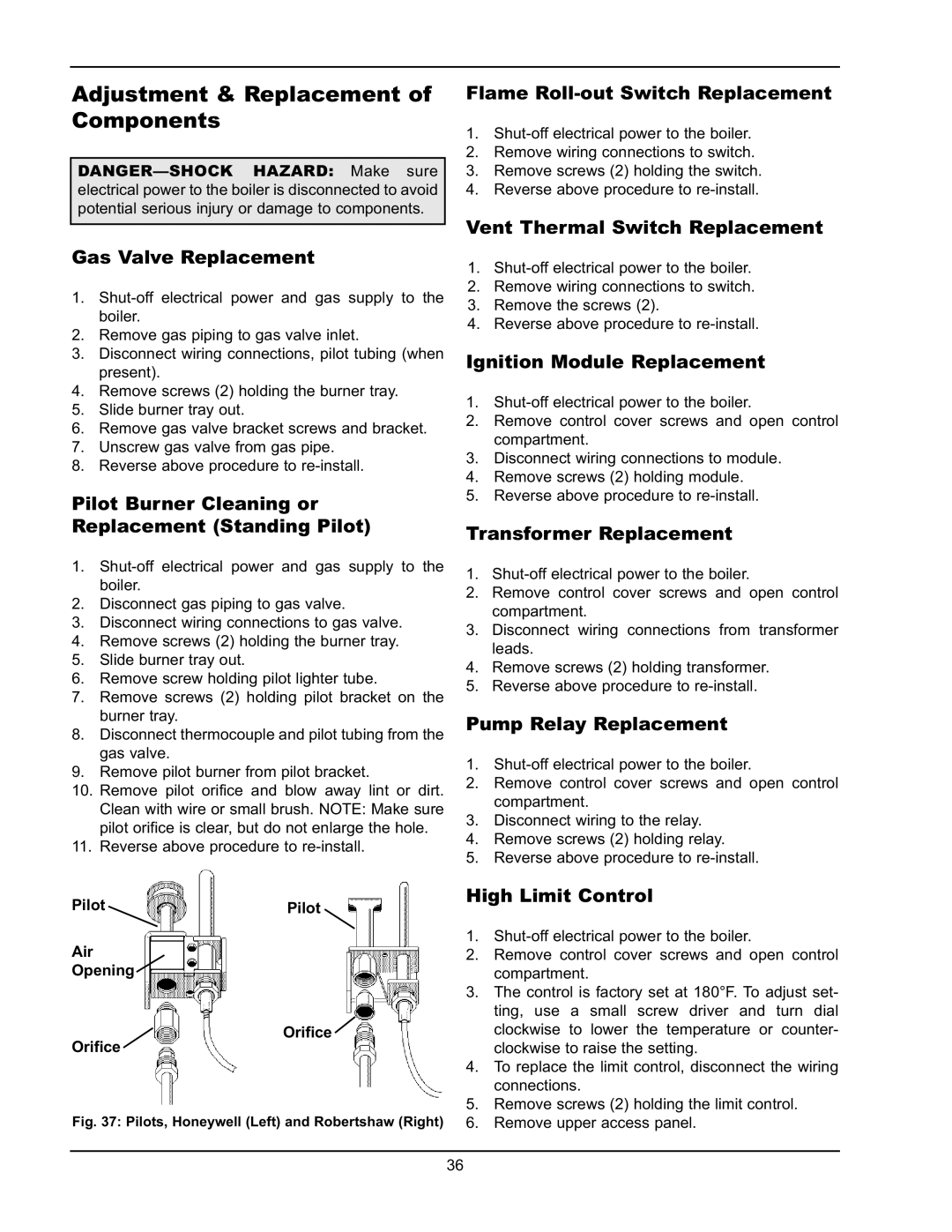

PilotPilot

Air

Opening

Orifice ![]() Orifice

Orifice ![]()

Fig. 37: Pilots, Honeywell (Left) and Robertshaw (Right)

Flame Roll-out Switch Replacement

1.

2.Remove wiring connections to switch.

3.Remove screws (2) holding the switch.

4.Reverse above procedure to

Vent Thermal Switch Replacement

1.

2.Remove wiring connections to switch.

3.Remove the screws (2).

4.Reverse above procedure to

Ignition Module Replacement

1.

2.Remove control cover screws and open control compartment.

3.Disconnect wiring connections to module.

4.Remove screws (2) holding module.

5.Reverse above procedure to

Transformer Replacement

1.

2.Remove control cover screws and open control compartment.

3.Disconnect wiring connections from transformer leads.

4.Remove screws (2) holding transformer.

5.Reverse above procedure to

Pump Relay Replacement

1.

2.Remove control cover screws and open control compartment.

3.Disconnect wiring to the relay.

4.Remove screws (2) holding relay.

5.Reverse above procedure to

High Limit Control

1.

2.Remove control cover screws and open control compartment.

3.The control is factory set at 180°F. To adjust set- ting, use a small screw driver and turn dial clockwise to lower the temperature or counter- clockwise to raise the setting.

4.To replace the limit control, disconnect the wiring connections.

5.Remove screws (2) holding the limit control.

6.Remove upper access panel.

36